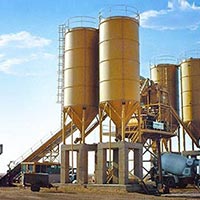

Ready Mix Concrete Batching Plant

4,500,000 Per Set

1 Set (MOQ)

ready mix concrete plant

Get Price Quote

1 Piece (MOQ)

Best Deals from Ready Mix Concrete Plant

ready mix concrete plant

1,900,000 - 2,500,000 Per Set

1 Set (MOQ)

ready mix concrete plant

Get Price Quote

1 Set (MOQ)

ready mix concrete plant

3,800 - 6,250 Per m 3

100 metrecube (MOQ)

ready mix concrete plant

Get Price Quote

We are counted among the top Suppliers of Ready Mix Concrete Plant. The best thing about our Ready Mix Concrete Plant is that it is well tested and has longer functional life. We make all arrangements for the proper installation of Concrete Plant at the clients’ end. Buyers prefer to obtain Concrete Plant from us as we make it available at the best market price.

Automatic Ready Mix Concrete Batching Plants

Get Price Quote

Concat - CTS Seris is a revolutionary designed model, in which we have used the design concept of very big capacity plants. The belt conveying system saves the time, reduces the maintenance and increases the output. This plant is suitable for RMC setup. Salient Features • Concrete Batching Mixing plant available in 456090 m3hr. capacity. • Aggregate stored by Inline Bins. • Aggregate weigh is suspended on Four “S” type load cells, gives higher accuracy. • Independent weighing system for AggregateCementWater & Additive. • Fully Automatic-Electronic operation with PLCPC Control. • Required installation time is very less, due to Modular design. • Available with Single Shaft Twin Shaft PANPlanetary type Mixers. • Reliable, Fast and Accurate Electronic Weighing System for major inputs. • Full service, technical support and spares back-up.

ready mix concrete plant

Get Price Quote

Jai Jawan Ready Mix Concrete Plant

Get Price Quote

Total Concrete Solutions Jai Jawan Business Group having established in the market of construction industries and we found a growth and need in the market for RMC, this motivated us to establish Jai Jawan RMC. The first unit was started in 2016. Quality of concrete: The quality of Mix Design is Certified Hitech Construction Material Testing Laboratory. rnTimeliness: Expertise planning of delivery and supported by adequate number of transit mixers. Material Management: Major of the material required for RMC is manufactured in-house and other required material is stored in ample. RMC Team: Our team has the best technical expertise in the Indian concrete and aggregate industries. The entire process is supported by latest technology. Modern Plant & Equipment: Fully automated plant with computerized control on the entire production process. Logistics: A large fleet of well maintained transit mixers with experienced drivers. Concrete Grades: We supply to the plants of some companies in the grades of M-7.5 to M - 60. All these products are available round the year. Training Programs: All team members are given safety measures on every half yearly basis under WOC policy.

ready mix concrete plant

4,500 - 6,000 Per

Ready mix concrete supply for only chennai. Minimum : M7.50 gread Maximum : M50 gread

ready mix concrete plant

Get Price Quote

The grade 43 and 53 in cement mainly corresponds to the average compressive strength attained after 28 days ( 6724 hours) in mega pascals (Mpa) of at least three mortar cubes ( area of face 50 cm squared) composed of one part cement, 3 parts of standard s and ( conforming to IS 650:1966) by mass and P/4 ( P is the ...May 22, 2013

ready mix concrete plant

Get Price Quote

AVP RMC is your premier destination for top-quality Ready mix concrete. As one of the trusted Ready mix concrete suppliers, AVP has firmly established itself as a significant name in the field of ready mix concrete with a commanding presence spanning many places across South India, including Tirupur, Trichy, Coimbatore, Chennai, and Chengalpattu. We have built a strong reputation for providing excellent concrete solutions and have never wavered in our commitment to quality throughout our journey.

Ready Mix Mortar

Get Price Quote

a1 quality ready mix plaster in wholesale price

ready mix concrete plant

2,450,000 Per Piece

1 Piece(s) (MOQ)

ready mix concrete plant

Get Price Quote

Produced at all project plants for use in the project, KMC Ready-Mix-Concrete is sourced for use at minimum notice with a division of the most current mobile volumetric batching plants.

ready mix concrete plant

Get Price Quote

ready mix concrete plant

2,200,000 Per Set

Stationary Ready Mix Concrete Plant

Get Price Quote

The Stationary Concrete Batching Plants are designed for ready-mix producers, contractors, precast Manufacturers and special applications. Furnished mainly with twin shaft mixers, also available with 0.5m3 and 1m3 planetary mixers. The plants are available in various capacities ranging from 50m3 to 240m3 per hour of compacted Concrete output and designed for operations under extreme conditions with highest performance. Special plant designs are available for dam construction and precast manufacturers. Ultimate modular design provides flexibility to adapt to site conditions and add on features as per Project requirements. Specially cast wear resistant parts keep maintenance time and cost at a very low Level. Turbo pan type mixer Imported planetary gear box Whole plant assembly on single chassis 2 x 2 Cross bin feeder Digital load cell based weighing Through inclined screw conveyor Turbine type flow meter based water feeding Auto admixture dozing system PLC based control panel with internal cabling

ready mix concrete plant

Get Price Quote

KAUSHIK Mobile Concrete Batch Mix Plant provides turnkey solution to ready mix Concrete BatchingMixing Plant. Our Concrete Batching Plant is one of the most efficient and versatile plants which is used on an international scale. KAUSHIK Mobile Concrete Batching plant is utilized in the construction of highways, bridges, canals, airports, industrial & multi-story buildings and ready mix concrete plant. Our mobile concrete batch plant not only makes concrete quickly but also ensure the high quality with no separation during discharge.

ready mix concrete plant

Get Price Quote

We installed our Ready Mix Concrete Plant in Pune in the year 2012 with the primary objective to save time and ensure satisfaction to our customers by providing superior quality as we manufacture all aggregate with our own crusher. We installed our Ready Mix Concrete Plant in Pune in the year 2012 with the primary objective to save time and ensure satisfaction to our customers by providing superior quality as we manufacture all aggregate with our own crushe Wide Range Concrete from M-10 Grade to M-50 Grade High grade concrete using silica and polypropylene fibre Dry Lean Concrete (DLC) Pavement Quality Concrete Colored Concrete Recently we have completed all the UTWT (Ultra Thin White Topping) concrete at Dahanukar Colony, Bhusari Colony, Gokhale Nagar, Rasta Peth, Sahkar Nagar etc. We are already into Concrete Road Projects from Excavation to PQC, with a vision to do Turnkey projects. Our Infrastructure:- Fully Automatic Plant of Schwing Stetter with computerized control. MCI 300 is a latest control system for batching plant. The batching process is controlled by the SIMATIC – 57 PLC and SCAOA Airtight Silos for cement and fly – Ash. Self own crusher for raw material like metal 10mm, 20 mm and Crushed sand. Transit Mixers for transportation Concrete pump of Schwing Stetter for pouring concrete. Our Quality Assurance Concrete Design Done By DOE Method Conforming IS 456-2000 & IS 10262-1982 Aggregates are confirming to IS 383-1970 and produced in total Quality at our Crusher of the art VSI Plant. Exclusive usage of OPC 43 Grade Cement Well equipped and well operated Lab Mix Designs from well known Organizations like CSRL- Structwel, Durocrete and COEP Our Technical Associates CSRL Structwel, Durocrete, COEP, Construction Excellence & Sharp Concrete Recent Completed Projects:-- Recently we have completed all the UTWT (Ultra Thin White Topping) concrete at Viman Nagar, Kharadi, Band Garden- Tadiwala Road, Gilding Center Helipad Work Hadapasar etc. We are already into Concrete Road Projects from Excavation to PQC, with a vision to do Turnkey projects.

ready mix concrete plant

Get Price Quote

Concrete Batching plant capacity 30m3hr with 4nos In-Line Bins and most advanced newly designed Planetary mixer and PLC based Panel of Command Alkon (USA) software. This ready mix concrete plant ensures complete homogeneous concrete quality with shorter cycle time. MEW 30 is most versatile cement concrete making plant for residential, commercial, Industrial, , Bridges, Road construction projects with many distinct features.

ready mix concrete plant

Get Price Quote

Concrete Batching plant capacity 90m3hr to 120m3hr with 4nos In-line Bins along with newly designed Twin shaft mixer and Planetary Mixer for low operating cost and Advanced SCADA with PLC based Panel of Command Alkon (USA) software, suitable for manufacturing Ready Mix Concrete and Dam works site.Apollo ATP 90 is robust plant serves majority industry needs for Ready-mix concrete. Used in infrastructure development projects where timely execution of project is a major challenge with consistent quality and flexibility.Option of Planetary Mixer or Twin shaft mixer, Consistency and uniform mixing in all batches.

ready mix concrete plant

1,400,000 Per Piece

ready mix concrete plant

Get Price Quote

Atlas asphalt concrete plant is also called as batching plant or batch plant. Available categories like portable concrete mixer, rmc (ready mix plant suppliers), small mobile mixing and stationary plant manufacturer in India.

Stationary Ready Mix Concrete Plant

Get Price Quote

The Stationary Concrete Batching Plants are designed for ready-mix producers, contractors, precast Manufacturers and special applications. Furnished mainly with twin shaft mixers, also available with 0.5m3 and 1m3 planetary mixers. The plants are available in various capacities ranging from 50m3 to 240m3 per hour of compacted Concrete output and designed for operations under extreme conditions with highest performance. Special plant designs are available for dam construction and precast manufacturers. Ultimate modular design provides flexibility to adapt to site conditions and add on features as per Project requirements. Specially cast wear resistant parts keep maintenance time and cost at a very low Level. Turbo pan type mixer Imported planetary gear box Whole plant assembly on single chassis 2 x 2 Cross bin feeder Digital load cell based weighing Through inclined screw conveyor Turbine type flow meter based water feeding Auto admixture dozing system PLC based control panel with internal cabling

ready mix concrete plant

Get Price Quote

ready mix concrete plant

Get Price Quote

This unit is suitable for a medium scale requirement and is available for 10 to 25 M3 capacities. Its design eliminates the need for foundation for the unit. Minimum power requirement and automatic control – PLC and SCADA – are salient features of this series. The specifications mentioned below are for 30 and 60 Cu.Mt./Hr respectively. This is one of the most compact batching units that Brickvision offers and is suitable for small scale concreting needs. The automatically operated and digitally controlled water and admixture feeding system ensures correct proportions every time and also increases operating efficiency of this unit. The specifications mentioned below are for 18 and 25 Cu.Mt./Hr respectively.

ready mix concrete plant

Get Price Quote

ready mix concrete plant, concrete block, Concrete Block Making Machine

ready mix concrete plant

Get Price Quote

ready mix concrete plant, Screw Conveyors, Belt Conveyor, Conveyors, Mortar

Ready Mix Concrete Plant (RMC Plant)

Get Price Quote

Ready Mix Concrete Plant (RMC Plant), Mini Crane Machine (150 & 2300 kg)