Fiberglass GFRP Rebar

Get Price Quote

8 Ton (MOQ)

Mild Steel Rebars

44,600 - 52,000 Per Metric Ton

25 Metric Ton (MOQ)

experience the strength of top-quality mild steel rebars with shree ji steel private limited, (formally shree ji steel corporation), your trusted steel dealer from kolkata, west bengal. our tmt bars, sourced from durgapur, west bengal, raipur, raigarh, chhattisgarh and jalna, maharashtra,promise robustness to your construction. at shree ji steel, we ensure that the might of steel reaches every corner of india, supporting your dreams and structures with unwavering stability. build with us, build with assurance! features: standardize new non rusted material. all materials are isi standard. all over india delivery. quick delivery. reasonable market price. accurate weight. weight chart: item diameter in mm tmt bar length in meters weight per meter in kg weight per 12 meter pcs (weight in kg) tmt bar 5.5mm 12 meter 0.154 1.848 tmt bar 8mm 12 meter 0.395 4.74 tmt bar 10mm 12 meter 0.617 7.404 tmt bar 12mm 12 meter 0.888 10.656 tmt bar 16mm 12 meter 1.580 18.96 tmt bar 20mm 12 meter 2.470 29.64 tmt bar 25mm 12 meter 3.850 46.2 tmt bar 28mm 12 meter 4.830 57.96 tmt bar 32mm 12 meter 6.310 75.72 *disclaimer* 1. rates: subject to change as per the hourly market situation and will be valid only after formal discussion. 2. grade: fe500, fe500d, fe550, fe550d, fe600 3. size available: 4.5 mm to 32mm 4. length: 12 meters. 5. tax: goods and service tax @ 18 % to be charged on the bill amount. 6. dispatch time: 1-7 working days. 7. transportation: to be charged extra.` 8. minimum order quantity: as per shree ji steel private limited our minimum order quantity is 25 metric ton. 9. dispatch location:durgapur, kolkata, west bengal, raipur, raigarh chhattisgarh& rourkela, odisha. jalna &mumbai, maharashtra. 10. packaging type: bundles /”u” bends. 11. payment modes: t/t (bank transfer), rtgs/neft, cheque. 12. payment 100% advance along with the order through bank transfer. 13. products are subject to availability.

Best Deals from Rebars

Hot Dip Galvanized Rebar

Get Price Quote

100 Piece (MOQ)

Industrial Rebar Bender

82,000 Per Piece

1 Piece (MOQ)

Glass Fiber Rebar

Get Price Quote

50 Meter (MOQ)

Fiberglass (Fiberglass Reinforced Plastic) rebar is made of high strength glass fibers along with an extremely durable resin. Non-corrosive: Will not corrode exposed to a wide variety of corrosive element including chloride ions. High Strength-to- Weight Ratio: - Provides good reinforcement in weight sensitive applications. Non-conductive:- Provides excellent electrical and thermal insulation. Excellent Fatigue Resistance:-Performs very well in cyclic loading situation. Good Impact Resistance: - resists sudden and severe point loading Magnetic Transparency:-not affected by electromagnetic fields: excellent for use in MRI and other types of electronic testing facilities. Light Weight: - easy to be transported, no need of lifting equipment, saving high machine and manual cost.

Steel Rebars

34,000 - 35,000 Per Ton

30000 Ton (MOQ)

Rebars

Get Price Quote

• We stuff 11.8 meter long Rebars with a U-fold inside 20’ FCL up to 16mm.• We stuff 5.8 meter long Rebars in all sizes inside 20’ FCL.• We can also supply 11.8 meters without a U Fold in 40’ FCL

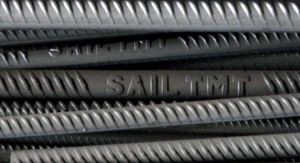

Shyam Steel TMT Rebar

61,000 Per Metric Ton

20 Metric Ton (MOQ)

B I U

FRP Rebars

Get Price Quote

20 Kilogram (MOQ)

Gfrp Rebar

Get Price Quote

ARC GFRP Rebars are being made as per ACI 440 guidelines and stringent quality measures undertaken at every stage, enabling it to deliver impeccable end products. For many years, there have been many studies on the corrosion issue with steel rebars, and the interest in FRP (Fiber Reinforced Polymer) has arisen recently as prospective substitute for steel. Careful consideration on potential of FRP rebar to fill the cost and performance needs may suggest appropriate solutions. Glass fiber-reinforced polymer rebar is one of the new products on the market that could offer a number of benefits to the construction and tunneling industry. Applications Fiberglass rebar may be a suitable alternative to steel reinforcing in: Architectural Concrete: column facades, window lentils, architectural precast elements, hand railing, and fountains, etc. Concrete exposed to de-icing salts in: bridge decks, railroad grade crossings, median barriers, parking garage elements, and salt storage facilities, etc. Concrete exposed to marine salts in: seawalls, water breaks, buildings & structures near waterfront, aquaculture operations, and floating marine docks, etc. Concrete used near electromagnetic equipment such as: MRI rooms in hospitals, airport radio & compass calibration pads, and concrete near high voltage cables, transformers, substations, etc.

TMT Rebar

55,000 - 60,000 Per MT

500 Metric Ton (MOQ)

Mild Steel Rebar

Get Price Quote

Produced out of premium grade supplies, our entire range is quality assured and conforms to global industry standards. The company shares glorious credentials with the leading suppliers of mild steel rebar and offers the best deal.

Steel Rebars

1,700 - 1,950 Per Kilogram

1 Kilogram (MOQ)

Glass Fibre Reinforced Polymer Rebar (GFRP Rebars)

100 - 200 Per kgs

100 kgs (MOQ)

JB Engineering Glass Fibre Reinforced Polymer (GFRP) Rebars (8mm,10mm,12mm,16mm,20mm,25mm,28mm,32mm, 36mm) tensile strength and twice stronger and four times lighter than TMT bars. These offers several advantages like corrosion resistance, stronger, lighter, cheaper are the important advantages of GFRP Rebars for Construction. JB Engineering Glass Fibre Reinforced Polymer (GFRP) Rebars offers several Advantages for Construction which can contribute to cost savings, improved sustainability, and enhanced construction efficiency and can be narrated as under: 1. Structural Integrity & Load-Bearing Capacity: GFRP Rebars provides the Strength which is necessary to support various loads, including dead loads , live loads , and environmental loads. 2. Durability: GFRP REBARS being a Strong materials and well-constructed structures are more durable and can withstand weather, aging, and wear and tear. GFRP Rebar is a corrosion-resistant material and increases the lifespan of construction. 3. Lower Transportation Cost: GFRP Rebars Being a Lighter material, is easier to transport and cost-effective. 4. Faster Construction: GFRP Rebars Being a Lightweight material, are easy to install and carry from one location to another. This can result in a faster construction process and reduce labour costs. 5. Design Flexibility: GFRP Rebars being a Lightweight material offers flexible design, allowing architects and builders to explore innovative and unconventional design options. 6. Non-metallic Composition: GFRP Rebar comprises Glass Fiber embedded with polymer resin. It lacks metal components and does not rust when exposed to moisture, oxygen, chemicals. These are resistant to a wide range of chemicals, including acids and alkalis, often present in corrosive environments. 7. Moisture resistance: GFRP rebar does not absorb water or moisture, a critical factor in preventing Corrosion. GFRP Rebar is highly resistant to saltwater, making it an ideal choice for marine and coastal construction projects. 8. Durability in Aggressive Environments: GFRP rebar excels in aggressive environments, such as wastewater treatment facilities, chemical plants, and structures exposed to de-icing salts or corrosive gasses. It maintains its structural integrity and does not corrode under these conditions. 9. Cost-effective: GFRP Rebar is a cost-effective material. It is a more robust, lighter, cheaper, Corrosion resistant, non- conductive material. It increases the life span of construction. It decreases the maintenance and replacement of construction. It is a cost-effective material. It is an ideal choice for construction.

Steel Rebars

Get Price Quote

Steel rebars, Based on the varied industrial applications, we make available wide range of Dowel Bars that are manufactured in different possible specifications Dowels Bars are Hot Rolled Plain Round steel bars conforming to ASTM A615A615M-09b Grade 60.

FRP Rebar

110 - 150 Per kg

TMT Rebars

Get Price Quote

Hailing from Tirupati(India), we are engaged in catering to all the customers by reaching their preferred destination. With us, clients can stay rest assured for the security of the payment. For the convenience of the clients, we accept cash payments along with bank transfers.

TMT Rebars

52,000 - 55,000 Per Per Ton

10 Ton (MOQ)

Note- Price will be change according to market Price.

Mild Steel Rebars

Get Price Quote

Mild Steel Rebars have a sturdy metal body with variable thickness and high durability. We have a well-developed all the in-house storage facility, laced with all the modern facilities. Also, we have hired a team of professionals who efficiently manage and maintain it. Obtain quality-grade Mild Steel Rebars from us at reasonable prices, as we are reckoned among renowned suppliers of the product.

Steel Rebars

30,000 Per Ton

20 Metric Ton (MOQ)