E Waste Processing Plant

Get Price Quote

1 Plant (MOQ)

Plastic Waste Recycling Machine

Get Price Quote

Specifications PE/PP film recycling PE/PP bottle recycling PET bottle recycling Other plastic The main components of the machine Crusher Hot washing machine (can be chased according the customer’s request) Washing machine Drying system

Best Deals from Recycling Plant

Construction And Demolition Waste Recycling Plant

Get Price Quote

1 Unit (MOQ)

tyre recycling machine

2,500,000 - 4,800,000 Per Unit

Water Recycling Plant

Get Price Quote

We Have An Entier Range Of Plant And Machienry For The Soap Industry. Starts From The Storage Tank To The Cartooning Machine;

Plastic Granule Recycling Plant Without Agglomeration

Get Price Quote

1 Piece (MOQ)

waste tyre recycle plant

Get Price Quote

We are manufacturer & exporter of waste tyre pyrolysis plants with 5 - 10TPD processing capacity. Pyrolysis plant is an industry that converts scrap tyres into Pyrolysis Oil, Carbon Black, Scrap Steel and Hydrocarbon Gas. The plant is manufactured using high quality material, is highly durable and has high performance level. To manufacture these plants, we make use of quality-approved components that are source from certified vendors. Features : 100% of waste tyre recycling is achieved ( no waste left after the process ) No chemical ingredients are used in process ( environment friendly ) During and after the process, No soil, water or air pollution is observed Creates economically valuable products out of waste ( all of the products are industrial raw materials that have a market value ) The most cost - effective waste tire recycling technology in the world Raw material ( waste tyre ) is cheap and easy to provide. These are the by-products of tire production Each recycled ton of tyre preserves 10 tons of Co2 that is a major green house gas The process can be applied to all rubber based materials The system creates an alternative source of energy to replace petroleum products and natural gas System gives the opportunity to governments and local administrations to deal with the waste tire problem to a great extent System prevents the spread of diseases caused by the waste tires We deliver plants with capacities of 10 ton per day and its multiples The process of pyrolysis has duration of 4 to 12 hours, depending on the amounts and the type of tire ( car tires, truck tires etc) During the process different vacuum values are applied in pre determined temperatures and in different phases, different gases are obtained and the condensed gas is stored as fuel - oil in tanks.

ac recycling machine

Get Price Quote

We are identified as one of the prime AC Recycling Machine Manufacturers in India. The Automatic AC Recycling Machine is manufactured using optimum quality materials ensuring high durability, robust structure and resistivity to adverse conditions. The components available with the AC Recovery Recycling Machine also ensure fast and efficient recharging, recovery and recycling of AC gas. Additionally, customers are also eased with the availability of the AC Recycling Machines loaded with all the advanced facilities.

scrap metal recycling Shredder Machine

500,000 - 1,000,000 Per Piece

1 Piece (MOQ)

The SHREDALL Scrap Metal Recycling Shredder Machine is a robust and efficient solution designed for shredding various types of metal scrap. It reduces large, bulky materials into smaller, manageable pieces, facilitating easier recycling and disposal. Our Manufacturer Unit is In Mumbai India, Our Shredder Machine is made of Hardened Metal and high-quality robust Blades. We deliver all over India and worldwide with full support and a warranty. Contact Us Now. The Working and Benefits of Scrap Metal Recycling Shredder Machine The shredder works by using powerful rotating blades to cut through metal scraps, transforming them into smaller fragments. This process not only simplifies storage and transportation but also enhances recycling efficiency by ensuring consistent material size. Benefits include reduced waste volume, lower transportation costs, and increased recycling rates. The machine operates by feeding scrap metal into the shredder, where rotating blades shred the material into smaller pieces, which are then collected for recycling or disposal. Key Features High-efficiency motor for powerful shredding Durable blades for long-lasting performance User-friendly control panel for easy operation Safety features to protect operators Shredding Material The machine is designed to handle a various metals, including aluminum, steel, and copper. Shredding Machine Type The Shredder Machine is a double shaft cross-cut type, which means it can shred waste materials into small, manageable pieces for further processing and recycling Usage/Application Ideal for recycling plants, metal processing facilities, and waste management companies. It helps in efficiently processing scrap metal for reuse and recycling. Capacity With shredder from 500 kgs/hr to 1000 kgs/hr , the machine is available for small , medium to large-scale operations. Automation Grade The Shredder Machine is fully automatic, which makes it easy to operate. Motor Power The machine runs on a 3 Phase power supply, ensuring efficient and reliable performance. Country of Origin Proudly made in India, SHREDALL industrial Shredder Machine is a testament to the country's manufacturing prowess. High Performance and Easy Installation The SHREDALL shredder offers high performance with its robust motor and efficient design. Installation is straightforward, with a user-friendly setup that ensures quick deployment and minimal downtime.. Product Description The SHREDALL Scrap Metal Recycling Shredder Machine provides efficient metal shredding, reducing bulk materials for easier recycling. It features durable blades, high-efficiency performance, and easy installation.

battery recycling machines

Get Price Quote

WE PROVIDE FULL TURN KEY PROJECT FOR LEAD RECYCLING PLANT INCLUDING FROM SHED MAKING, PLANT SETUP, ERRECTION INSTALLATIONS, TRAINING, MANPOWER, TECHNICAL SUPPORT, CONULTANCY, AFTER WARRANTY SERVICES, AMC CONTRACTS WORLDWIDE, PLANT CARE TAKING, WE HAVE PLANT FOR 2MT LEAD PRODUCTION TO 100MT PRODUCTION PER DAY.

Plastic Recycling Machine

Get Price Quote

We are the exporter and supplier of this products.

Plastic Recycling Machine

Get Price Quote

organic waste compost machine

800,000 Per Piece

1 Piece (MOQ)

Industrial Waste Paper Recycling Machine

30,000,000 Per Piece

1 Piece (MOQ)

waste paper recycling machine

1,250,000 - 1,300,000 Per Piece

1 Piece(s) (MOQ)

Mini Recycling Granulators Machine

Get Price Quote

1 Unit (MOQ)

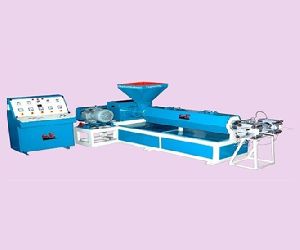

Trim Recycling Machine

Get Price Quote

1 Piece (MOQ)

TRIM RECYCLING MACHINE Edge trim unit was introduced on the basis to the subject of “Green Eco Friendly” awareness to the Plastic Film production industry. The unit cleverly integrated advanced structural design with Innovative concept for reclaim trimmed film edge uninterruptedly within the system. The process starting from edge trim feeding, cutting and feeding in the extruder, all in one complete process promised to save labor cost, power consumption and process time.

Plastic Recycling Machine

350,000 Per Piece

1 piece (MOQ)

Lead Recycling Air Pollution Control Plant

2,000,000 Per Set

1 Set (MOQ)

Aluminum Recycling Plant

100,000 Per Piece

1 Piece (MOQ)

We Supply Crucible Melting Furnace Our Product Range Includes Melting Furnaces, Holding Furnaces And Melting Cum Holding Furnaces.Furnaces Are Available In The Following Fuel Options1. Electric Furnace With Plc Panel And Auto Temperature Cutt Off2. Diesel Fired Furnace3. Furnace Oil Fired Furnace4. Gas Fired Furnace5. Petcoke Furnace6. Wood Fired Furnace