Refractory Bed Material

Get Price Quote

1 Metric Ton (MOQ)

The Boiler Bed Material is a very critical product and is considered as the lifeline for fluidized bed boilers. We have carved a niche as one of the prime Manufacturers and Suppliers of Refractory Bed Material for both FBC & CFBC boilers.

Refractory Boiler Bed Material

Get Price Quote

25 Ton (MOQ)

Best Deals from Refractory Bed Material

Refractory Bed Material

Get Price Quote

Our company is an experienced name, which is counted among the top Manufacturers, Exporters and Suppliers of Refractory Bed Material from Haryana, India. It is perfect for obtaining smooth fluidization in the Boilers. Our Refractory Bed Material has high alumina content and dense texture. When it comes to delivering Refractory Bed Material, we use fast shipment modes that ensure its prompt and timely delivery at the customers� end.

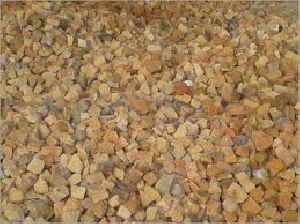

Crushed Refractory Bed Material

Get Price Quote

100 Kilogram (MOQ)

Refractory Boiler Bed Material

Get Price Quote

1 Ton (MOQ)

Refractory Bed Material

Get Price Quote

Refractory Bed Material

Get Price Quote

30 Ton (MOQ)

Refractory Bed Material

Get Price Quote

Due to the capacious and well-maintained storage unit, we keep a large stock in a safe place to ensure complete safety. This unit also helps us in maintaining high quality standards. Only after getting approval from the quality experts, we make use of the inputs sourced from the vendors. We make sure that our entire range is of excellent quality and faultless. Crushed Fire bricks castables IS8 grade or River silica sand.

Crushed Refractory Grog

Get Price Quote

If you are looking for a Crushed Refractory Grog manufacturer, you are in the right place. Kirti Mineral Works have the best products that meet everyone’s needs and requirements. Based in Raipur, we provide our products to customers all around the world. Crushed Refractory mortar Grog produced from fine-grained refractory aggregate, refractory powder, binder and other additives and used for building and bonding the refractory bricks, and also repairing of furnace lining, which is mainly used in glass furnaces, hot blast furnaces, coke ovens, soaking furnaces, heat exchangers, boilers and other industrial kilns. Why Choose Products From Us? Our refractory mortar is ready to use for the lining of firebricks and insulation bricks. Used for sealing and repairing furnaces, kilns, combustion chambers, boilers, fireboxes, flue pipes, stoves, ducts, chimneys, and many other furnaces and refractory applications. • Ready to use • Easy application • Wet Refractory Mortar • High-Temperature Refractoriness • Make sure mortar is completely dry before applying heat We being in this market for years understand the needs and requirements of our customers and clients and produce products accordingly. These products are tested on different parameters to ensure that it meets the needs and requirements of our customers and clients. Choose us and get our products without any delay. Call us and get our services. If you have questions or query call us or send us an email. We will give instant replies and will clear all your doubts.

Refractory Bed Materials

3,500 - 6,000 Per MT

5 Metric Ton (MOQ)

Refractory Bed Material

Get Price Quote

With us, payment transactions will always remain secured, as we have adopted modern payment procedures that guarantee instant and hassle-free transactions. We are counted amidst the well-known names based in Cuddalore(India) and cater to every nook and corner.

Refractory Boiler Bed Material

3 Per Kilogram

Refractory Bed Material

4,450 - 4,650 Per ton

30 ton (MOQ)

Crushed Refractory Bed Material

400 - 1,500 Per Bag

10 Metric Ton (MOQ)

refractory bed material of low ferric high temperature super quality is made out of high quality and super heat duty refractory aggregates of high alumina contents & dense texture. this very special bed material has many special characteristics that made it a perfect material for obtaining smooth and perfect fluidization use in fluidized bed combustion boilers (fbc) and circulating fluidized bed combustion boilers (cfbc). crushed refractory bed material for afbc ,cfbc and pfbc boilers

SS & MS Refractory Cassetter

Get Price Quote

PP cassettes, SS refractory cone and all type of nozzle items are manufactured here. Top Plate and Bottom plate both Centre and Off Centre.

Refractory Bed Material

3 - 6 Per Kilogram

21000 Kilogram (MOQ)

All type of boiler refractory bed material supplied,size of 0.86 to 2.36mm AFBC,CFBC,Incinerator boiler used

Refractory Bed Material

3,000 - 5,000 Per Ton

100 Ton (MOQ)

Operating from Wankaner (Gujarat, India), we are offering refractory bed material in different grain sizes varying from 0.5-2.36 mm And as per client requirement. Besides, clients can place bulk orders; we assure on time shipments.

Refractory Bed Material

Get Price Quote

We offer refractory bed material. We are recognized amongst the midst the most reliable refractory material manufacturers in india. The refractory bed material is used for smooth and perfect working of circulating fluidized bed combustion boilers (cfbc) and fluidized bed combustion boilers (fbc). Additionally, the unmatched quality and exhibition inexplicable performance in respective application has attracted clients from all over india to place huge and repeated orders. Customers are also eased with the delivery of the refractory bed material fire bricks within the stipulated time frame. brand alumin % min. silica % max. alkali % max. grading range (mm) average particl size mm bd gm/cc intical def. Deg. Cent. Bcpl bm (c) 32-35 52-55 0.5-1.0 0.9-2.8 0.9 1.1 1400 bcpl bm 27-29 67-69 1.5 0.8-3.0 0.9 1.1 1400

Refractory Boiler Bed Materials

Get Price Quote

SPECIFICATION FOR REFRACTORY BED MATERIALS I S 06 1) 100% WILL PASS THROUGH 8 MESH AND RETAIN OVER 20 MESH2) BULK DENSITY 1050 TO 1100 Kgs/m33) fusion temp 1400 *

Refractory Bed Material

Get Price Quote

Enlisted below are the noteworthy quality attributes of low cement castables : Fully resistant against clinker formation Accurate particle size distribution Low alkali low iron contents Perfectly controlled density Exceptional chemical purity Perfect product for obtaining fluidized action High I.D.T. (initial deformation temperature) Fully screened material free from fine particles No free iron particles - passed through iron separators Features : Research & Development - The Bed Material has been developed is a result of our own constant in-house research and development work and field experience for over 25 years; and also in accordance with the technical support / guidance from time to time extended by the leading manufacturers of FBC and CFBC Boilers like BHEL, TBW. The technical criteria and particle size distribution of the material is predetermined for practicality as well as economy of the product on the basis of technical requirement with specific fuel and boiler design. Special Characteristics – Refractory Udhyog Bed Material has many special attributes that makes it a transcendent material for FBC and CFBC Boilers with greater scale of economy. Zero wastage - Low consumption – Fully Screened Material - Perfect Size: Free from Fines & dust and over size particles separated through Air Classifiers. This subsequently eliminates wastage of material through air while in operation. Perfect Material and Particle Density gives perfect and smooth fluidizing action and enhances its Low Consumption properties. Uniform Heat - Accurate Intermediate Particle Size Distribution in required percentage of our product gives uniform distribution of heat / temperature in boiler bed area. ultra-responsive Particles Grain size : Min - 0.85 mm to Max - 1.5 mm Min - 1.00 mm to Max - 2.00 mm Min - 1.50 mm to Max - 2.5 mm Min - 2.5 mm to Max - 3.5 mm Micron Min - 650 mm to Max - 850 mm Note : Particles Variation Will Be 5/10% Allowed. Resistant against Clinker Formation The Low ferric chemical property and High Initial Deformation Temperature (PCE value) makes it highly resistant to abrasion and an ideal product against clinker formation at high temperatures. Safest product for boiler tubes Highly Exceptional Chemical Purity and low alkalis makes it neutral in chemical nature that gives longer life to boiler tubes and refractory lining as it has no chemical reaction with boiler tubes and carbon fuel. Due to its smooth operational properties and long particle life it results in low down time and maintenance cost. Economy of Product It has been observed that our Refractory Bed Material gives a saving of over 45% on its use on account of perfect size, low wastage, better quality and chemical properties, high refractoriness, high temperature properties, low operating consumption and minimal down time in comparison to other similar local products. The product has wide acceptance all over India and Overseas and is being regularly used by almost all FBC and CFBC Boilers of BHEL, Thermax etc. The product has no match and none to second, as it is excellent in operational properties and performance.