Refractory Gating System

10 - 100 Per Piece

1000 Piece (MOQ)

Shaped Acid Resistance Bricks

Get Price Quote

1000 Piece (MOQ)

Best Deals from Refractory Bricks

HFK Insulation Bricks

Get Price Quote

Acid Proof Bricks

Get Price Quote

By making use of premium packaging material, we can guarantee zero damage during transit. Moreover, our packaging experts stringently check the entire lot prior to final dispatch. Our fast and modern transit facilities enable us to deliver the orders within the stipulated time frame.

Fire Bricks

Get Price Quote

100 Kilogram (MOQ)

We offer superior quality Fire Bricks in the market. We are efficiently manufacturing every type of refractory products like Fire Bricks, Mortar, Castables etc. We have links with prominent and recognized manufacturers of refractory materials. We provide Fire Bricks to you as per your requirement within stipulated time frame.Specifications IS6 IS8 AL2O3-40% AL2O3-60% AL2O3-80% FIRE BRICKS BLOCKS -40% 60% Applications of Fire BricksWe have dd klin as well as Rotary Klin. We use Calcined Bauxite for manufacturing of Fire Bricks. For Chimney flue, Boiler, cupola, steel foundry. For cement preheater cyclone, silicate furnace & others moderate heat duty applications. For cement preheater cyclone, silicate furnace & others moderate heat duty applications. Special purpose low iron high duty bricks for cement preheater cyclone Special purpose low iron high duty bricks for cement preheater cyclone chemical plant sulphur furnace Low porosity dense bricks for anode baking furnace & blast furnace. For cement kiln, preheating zone, preheating furnace wall For cement kiln, preheating zone, reheating furnace wall. Calcination zone of cement rotary kiln, copper melting furnace. Reheating furnace wall, burning zone of cement rotary kiln, ladle backup. EAF roof, ladle lining & other high heat duty special application Dense bricks for petroleum, fertilizer, Aluminum industry. Dense volume stable bricks for reheating furnace roof, petroleum plant For glass industry & frit furnace application. For CS2 furnace sulphur furnace, Alkali resistant bricks for cement rotary kiln, Low porosity dense bricks for blast furnace, glass tank furnace, glass tank furnace & frit furnace. For burning zone of cement rotary kiln For burning zone of cement rotary kiln Lime kiln & burning zone of cement rotary kiln.

Zirmul Bricks

20 - 450 Per Piece

25 Ton (MOQ)

Refractory Bricks

Get Price Quote

We are a Manufacturer, Supplier and Exporter of Refractory Bricks. These Refractory Bricks can withstand high temperature and have low thermal conductivity thus, ensure great energy efficiency. Owing these attributes, Refractory Bricks can be used for lining the furnaces of Steel, Cement and Glass, where mechanical, chemical, or thermal stresses are involved. We offer Refractory Bricks in different specifications to cater diverse demands of the clients.

Fire Brick Refractory

Get Price Quote

Refractory Fire Bricks IS8

32 Per Piece

500 Piece (MOQ)

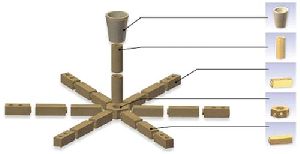

ARPL Bottom Pouring Set

Get Price Quote

The Bottom Pouring Set is made up of materials such as Fire Clay , Refractory Grog and Non Plastic Clay mixed up in fraction and then are pressed under hydraulic pressure so that desired shapes can be offered . The sets are highly resistant towards Thermal pressure and are known to offer the perfect shape and dimensions to the moulds. Sets can tolerate a temperature that is higher than 1350 Degree Celsius . Sets can Eliminate the refractory contamination such as carbon .

Fire Clay Bricks

Get Price Quote

We are listed as one of the most eminent Fire Clay Bricks Suppliers in India. The countable features of Fire Clay Refractory Bricks i.e. high durability and resistivity to various temperatures have attracted various clients from every nook and corner of India. Additionally, we also provide Wholesale Fireclay Bricks at the most profitable deals.

Clay Bricks

Get Price Quote

1 Container (MOQ)

Magnesia Carbon Bricks for Ladle

Get Price Quote

100 Piece (MOQ)

We stand tall as a reliable Manufacturer, Exporter and Supplier of Magnesia Carbon Bricks for Ladle from Gujarat, India. Perfect dimensions, sturdy construction and superb strength are the highlights of our Magnesia Carbon Bricks for Ladle, which is why they are the primary choice of the buyers. Whether it is a small order or bulk one, we will deliver the order within the promised time frame for sure!

HFK Insulation Bricks

40 Per Piece

1250 dig.

Rectangular Refractory Fire Brick

25 Per Piece

Insulation Bricks

Get Price Quote

5000 Piece(s) (MOQ)

Acid Resistant Bricks

Get Price Quote

Globe Carbon Industries is the name that is always recommended for prevention from corrosion problem such as acid, alkali and solvent often related to floor, tanks, platforms surface acid pits and other process equipments. To overcome these types of repeated problems, we have developed Acid Resistant Bricks. Our Acid & Alkalis Resistant Bricks and Tiles can withstand the most corrosive chemicals typically prevailing in majority of chemicals industries. We produce Acid Resistant Bricks in different thicknesses, sizes and weights to meet the specific construction requirements. And it is because of our capability to come up with a large variety that we have enlisted ourselves amid the leading Acid Resistant Bricks Manufacturers, Exporters and Suppliers in Maharashtra, India. Suitable For Chemicals process industriesSteel millsElectrolytic plantsOil refineriesRayon millsDyes & pigment plantChlorination plant Purely in acidic conditions Lining Procedure Total surface preparation is required to clean the surface neat, clean & free fromoil & grease. Application of impervious mastic memberance as a primer; to be applied between the surface & brick lining. Bedding with K-Silicate / Sodium silicate mortars. Potrassium silicate base cement which resists against wide variety of acids & entire range of temperature upto 800oC. Two part mixture, powder to Liquid 3 : 1 ratio.Sodium silicate Base cement which resists temperature upto 650oC can be use as bedding materials of A.R. Brick lining. Two part mixture, powder to liquid 3 : 1 ratio. Joining will be done with silica furan base cement from top & nearly 5mm deep inside to protect the surface from corrosion. Two part mixture, powder to furan syrup 3 : 1 ratio.

Rotary Kiln Bricks

Get Price Quote

3000 Piece (MOQ)

Refractory Alumina Bricks

39 Per Piece

1000 Piece (MOQ)

High Alumina Bricks

24 - 100 Per Piece

20 Metric Ton (MOQ)