High Alumina Refractory Castable

750 - 3,500 Per Bag

1 Bag(s) (MOQ)

Our Special range of Monolithic Castable Refractory Products are manufactured from a homogeneous mix of different fractions of special aluminous materials, fused alumina, and calcined bauxite etc. in different grades, types and temperature applications at different temperature.The entire range of High temperature Refractory Castables aand Monolithic refractory products are offered off-the-shelf for various immediate needs of industrial refractory management Solutions.Products offered DS Cast-135N / Fire Crete Normal DS Cast-140N / Fire Crete Super DS Cast-170N / Whytheat 'A' DS Cast-160N / Whytheat 'K' DS Cast-150N / Whytheat 'C' Dalset-50 HSM/Accoset-50 DS Cast 11 LW / Insulyte-11 Acid Proof Cement

Refractory Castable

Get Price Quote

100 Kilogram (MOQ)

Best Deals from Refractory Castables

Refractory Castables

Get Price Quote

We provide a wide range of high quality Refractory Castables that is widely used in the power plants, sugar plants and various other sectors. Our High Alumina Refractory Castables are perfect for the back-up and hot face linings. Our High Alumina Refractory Castables are comprised of high quality raw materials that ensure their excellent performance. Low thermal conductivity as well as low density of our High Alumina Refractory Castables assures conservation of heat energy. Moreover, to keep the properties intact for a longer period of time, our High Alumina Refractory Castables are available in quality packing. We are counted among the prominent High Alumina Refractory Castables Suppliers based in India. Special Features Perfect for backup and hot face liningsMade from optimum quality materialsLow thermal conductivityConservation of heat energy Widely Used In Steel industriesGlass IndustriesFurnacesMachine manufacturing units

Conventional Refractory Castables

10,000 Per Metric Ton

Raw materials that we source from the trusted vendors are used as input in the production procedure and thus we check them against varied quality parameters before procurement.These castables are widely appreciated among the patrons for their brilliant attributes such as purity, effectiveness and accurate composition.

castable mortar

300 - 2,000 Per Bag

25 Ton (MOQ)

Thermocoat-M - Refractory Castables

Get Price Quote

100 Kilogram (MOQ)

Our company is a reputed Manufacturer, Supplier and Exporter of Thermocoat-M from Gujarat, India. Customers from all over the world prefer our product because of their easy & multiple application methods, great adhesion power and low maintenance. We are proficient in handling bulk orders of Thermocoat-M and ensuring their timely delivery. Thermocoat-M Zirconia rich refractory coating compound, is developed specially to Protect Refractory linings, Monolithic, Ceramic Fiber Modules, Castables, Kiln/Furnace Steel Shells, Chimneys, Boilers, Kiln Furniture, Ferrous – nonferrous metals, melting crucibles, etc. against severe attacks and sandblasting effect of fumes, chemicals and molten metals at low/high temperature. The use of Thermocoat-M is highly advantageous in industries where continuous high temperature heating, burning- oil – erosion/corrosion is a chronic problem.Thermocoat-M is zircon rich refractory coating compound containing high percentage (63%) Zirconia and is most ideal for ferrous and non ferrous metals and refectories except Aluminum metal. Thermocoat-M protects from corrosion erosion, chemical fumes and flue gases escaping from heating chambers and severely affecting metals and refractory and reducing their service life.Applicatios – Procedurer : Mixing : Dry mix thoroughly Thermocoat-M powder, add clean tap water to it approx. 300ml to 1kg Powder. Mix them till homogenous slurry like consistency is achieved. Adjust the water amount to suit your application need. Consume the mix within 2-3Hours. Application : Apply Thermocoat-M by brushing / spraying / toweling on the surface to a thickness of around 1mm as per the need arises. Coverage : 03.0 kg Thermocoat-M covers around 1 mm thick one Sq.Mtr area however coverage of Thermocoat coating depends upon surface conditions. Main Chracateristics And Advantages Of Thermocoat-M : Easy to mix. Easy to apply by trowel ling, brushing or spraying. Good adhesion to metal, refractory bricks, monolithic, castable and ceramic fiber modules. Excellent dry strength, resistance to powdering. Good chemical resistance. Gas-tight surface without spelling or cracking. Considerable increase in service life of refractory lining and heating systems. Reduction in slag adhesion. Protects metals and refractory from destructive heat escaping from the heating ducts and combustion chamber, creating corrosion and cavitations etc. Thermocoat-M coating will be great benefit to use in Rotary, Roller Kiln, Chimneys, Boilers, Ducts, Kiln Furniture. Reduces expensive maintenance and plant shut down cost considerably.

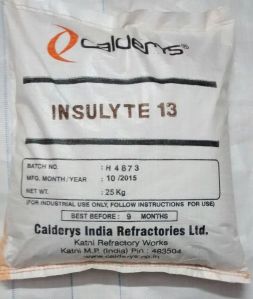

Insulyte 13 Refactory Castable

Get Price Quote

10 Piece (MOQ)

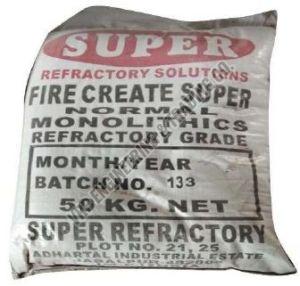

monolithic refractory castable

Get Price Quote

100 Bag (MOQ)

SR Cast 90 Refractory Castables

36 Per Kilogram

50 Kilogram (MOQ)

Whytheat K Refractory Castable

27 Per Kilogram

1 Ton (MOQ)

refractory insulating castables

Get Price Quote

30 Ton (MOQ)

Refractory Castables

6,500 Per Metric Ton

0.050 Ton (MOQ)

We provide a wide range of high quality Refractory Castables that is highly appreciated in the national and international markets. Today, we have carved a niche as one of the leading Manufacturers of Darley Refractory Castables. Our Refractory Castables are manufactured from the optimum quality raw materials to add durability and strength. Highly valued in the quality cautious markets, our Refractory Castables are in compliance with the national and international quality standards. To meet the different needs of the clients, our Refractory Castables are available in various specifications.

Refractory Castable Cement

300 - 600 Per Kilogram

1 Metric Ton (MOQ)

Refractory Castables

Get Price Quote

We are one of the eminent Manufacturers & Suppliers of Refractory Castables from Gujarat, India. Our range of Castables is widely used in furnaces, kilns, chimneys, etc. We use premium quality chemicals and the cutting-edge technology for fabricating the Castables in accordance to set industrial standards. To ensure its longer life span, we check the Refractory Castables on stringent quality parameters before approval for the final delivery. Features : Precise composition Long shelf life Optimum quality

Refractory Castables

Get Price Quote

Conventional Refractory Castables

Get Price Quote

Medium purity Conventional Refractory Castables are mainly our BC cast brand refractory castables, which are suitable for use in medium temperature application. This group of Dense Refractory Castables contains medium purity cement as the refractory binder. All these castables are used in oxidizing atmospheres only. We are renowned among the most dependable Alumina Conventional Refractory Castables Manufacturers in India. The dense refractory castables are of hydraulic setting that further assist in casting or moulding in any shape and are also modified for gunning of furnace linings.

Whytheat-K

60 Per Kilogram

100 Kilogram (MOQ)

Refractory Castables

Get Price Quote

Refractory Castables are used as protective of lining material in building of heat treatment furnaces, ovens, boilers, cupola etc. It is used along with Fire Bricks for better castability and strength. Based of the temperature, time and kind of heat to which lining material is exposed, various grades refractory castables can be selected. We supply Refractory Castables of Following Make Ace Caldreys Ltd. Orient Abrasive Ltd (Ashapura Group)

Refractory Castable

500 - 600 Per Bag

100 Kilogram (MOQ)

Refractory Castables

Get Price Quote