Product Reverse Engineering Services

Get Price Quote

Unlock the secrets of your competitor's products with our expert Product Reverse Engineering Services. We meticulously deconstruct and analyze products to reveal their materials, components, and manufacturing processes. This valuable insight allows you to innovate and improve upon existing designs, optimize production costs, and enhance product performance. Whether you're looking to replicate, innovate, or enhance, our team provides detailed reports and recommendations tailored to your needs. Partner with us to gain a competitive edge and drive your business forward with superior products.

Reverse Engineering and Design Services

Get Price Quote

1 Piece (MOQ)

With the sincere efforts of our experienced professionals, we have been able to provide our clients superior quality Reverse Engineering Service. The provided service is rendered using excellent quality inputs. Apart from this, owing to its flawless execution, and promptness, this service is valued by our clients.Other Details: Perfect work On-time completion Quick service Execution in tandem with clients detailed guidelines

Looking for Reverse Engineering Services Providers

Reverse Engineering Services

Get Price Quote

Our reverse engineering services unlock the secrets of existing products or systems, offering valuable insights for innovation, improvement, or replication. Using state-of-the-art technologies and methodologies, we meticulously analyze and deconstruct components, structures, or processes to understand their functionality, materials, and design principles. Key Features: 1. Comprehensive Analysis: With a keen eye for detail and engineering expertise, we conduct thorough analysis and documentation of existing products or systems. This includes examining components, materials, and design intricacies to uncover hidden insights. 2. Precision Documentation: We utilize advanced tools and techniques to create precise CAD models, schematics, or prototypes based on our findings. This enables us to accurately replicate or enhance existing designs for various purposes. 3. Innovation and Improvement: Whether it's for product enhancement, troubleshooting, or competitive analysis, our reverse engineering solutions empower businesses to drive innovation and stay ahead in today's dynamic market. By understanding the inner workings of existing products, we provide opportunities for improvement and differentiation. 4. Collaborative Partnership: Partner with us to unravel complexities, optimize performance, and drive innovation in your projects. We work closely with clients to understand their specific needs and goals, delivering customized solutions that meet and exceed expectations. With our reverse engineering expertise, businesses can gain valuable insights, optimize performance, and drive innovation in their projects. Let us help you unlock the full potential of your products or systems.

Reverse Engineering Design Services

2,000 Per hours

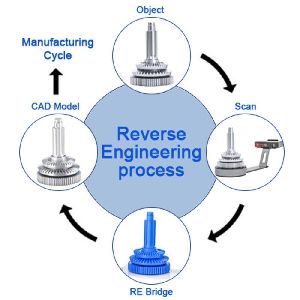

These are the most common uses cases of reverse engineering with a 3D scanner : Making a new part from an existing design Making a new part in interface with an existing part Understanding a competitor’s design Optimizing an existing design A crucial step for bringing any product to reality is getting an accurate manufacturable CAD file. Hence converting an STL file output from the 3D scanner to a parametric CAD file is very important. At Solid Vision, we have an expert team and an experience of more tha 2 decades in the field of Reverse Engineering. Why Us? More than 2 Decades of experience. State of the art technology. Competitive pricing Customized solutions based on your exact requirement.

Reverse Engineering Services

Get Price Quote

Aero Track Circuit has become a prominent name in the service sector of Surat (Gujarat, India). We are in the business of providing top-class reverse engineering services to the clients. Ours is a group of meticulous professionals, who are proficient in deconstructing a man-made object to reveal its designs, architecture, or to extract knowledge from the object. Our professionals are widely known for accomplishing their assigned tasks in the stipulated timeframe. Connect with us now by dialing our numbers to avail our services.

Reverse Engineering Services

Get Price Quote

We provide reverse engineering services. We make 3d model on cad by measuring actual part. We convert 2d drawing to 3d model.

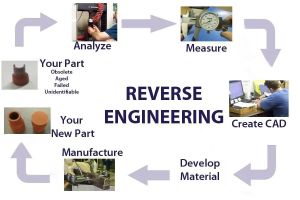

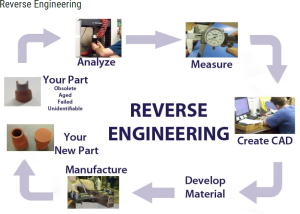

Reverse Engineering Process

Get Price Quote

SIMTEK, a leading SOLIDWORKS reseller in Chennai, Coimbatore, Kolhapur & the rest of Tamilnadu, and India brings inspiring capabilities to reverse engineering. In the highly competitive global marketplace, manufacturers are constantly looking for ways to shorten the time to market a new product. More and more manufacturers are opting for reverse engineering services because: The original manufacturer of a product no longer produces a product. There is inadequate documentation of the original design. The original manufacturer no longer exists, but a customer needs the product. The original design document was lost or never existed. Some bad features of a product need to be designed out. New avenues need to be explored to improve product performance and functionality.

Reverse Engineering

15,000 - 25,000 Per Unit

Leveraging cutting-edge DevOps software, our Engineering Services for streamline development cycles, ensuring rapid, error-free deployments. From code creation to continuous integration and delivery, our approach integrates seamless collaboration across teams, fostering agility and innovation. Automated testing and deployment pipelines enhance efficiency, while monitoring tools provide real-time insights, enabling proactive adjustments. With our DevOps-driven methodology, we empower businesses to accelerate time-to-market, reduce costs, and deliver high-quality products that meet evolving market demands. Design and Development services (3D model /2d drawings) Customised Prodcuts / Parts /Assemblies /Testig setups Anodizing for aluminium (Soft /Hard) High wear resistance coatings Casting / forging products can be supplied as per drawing

Reverse Engineering Services

Get Price Quote

We are providing reverse engineering services. As we have combined our extensive experience in reverse engineering & industrial designing to create a multi disciplinary product development group dedicated to offering the best possible services for small as well as large companies. We have facilities to capture data from smallest components to a complete aircraft, vehicle or the entire wind mill blade. So, if you are thinking about reverse engineering, just give us chance to help you out for your project, we are sure that you will have delighted experience with engineering cad cam solutions services.

Reverse Engineering Services

Get Price Quote

reverse engineering services is taking apart a product/part to see how it works in order to duplicate or enhance the object. With an increasing demand for superior products, companies analyze the existing products and benchmark them for possible design improvements. One of the ways to achieve this is ‘reverse engineering’. digital dynamics offers customized reverse engineering services. Our engineers have years of experience analyzing and designing products, parts and assemblies from simple to complex. Reverse engineering a product is an efficient and cost-effective way to apply for and protect patents, design future product upgrades, find ways to lower production costs or improve product performance or comply with third-party audits.our product development team, leverage years of industry experience, access to sophisticated computer-aided design (cad) technologies, coordinate measuring machines (cmm), laser scanners, and cutting-edge production facilities to provide reverse engineering. As part of this service, we can provide documentation, design specifications, materials analysis, cost projections and prototyping. we have the expertise in utilizing the latest technology components and incorporating them into existing machine tools to increase the overall output. Complete re-engineering of a machine can be undertaken in which new features are included. Machine can be rebuilt to the original specification. For many years we have looked after the rebuilding and re-engineering of a wide variety of machines. We offer engineered solutions in order to meet a range of customer's business challenges, including the need for increased capacity and providing upgrades to their existing machinery.our capabilities include tear-down analysis physical characterization material characterization cad modeling of the parts and assemblies creation of preliminary drawings and assembly layout drawings tolerance allocation & tolerance analysis creation of manufacturing drawings creating prototype .

Reverse Engineering Services

Get Price Quote

Nikita CAD/ CAM Solutions is a New Delhi, India based company, involved in providing reverse engineering services to the clients since 2004. We are providing services for components like plastics, aluminium, sheet metal, rubber, brass, die casting, etc. or as per clients’ requirements. We make use of freeform image ware and I-DEAS software for completing the undertaken task. The assigned task is executed by our industrious professionals. Over the years, we have acquired a remarkable space in this sphere. Contact us for availing our services at economical rates. Details : Plastics Rubber Brass Aluminum Sheet Metal Die casting

Reverse Engineering Design Services

Get Price Quote

Reverse Engineering is defined as the process of evaluating physical properties of an object to determine its structure, size, shape or utility. Earlier methods of reverse engineering involved manual measurement of the part’s dimensions and then utilize these details in CAD. Now CMMs and scanners are available to quickly capture the sample product shape and convert into a 3D model for further refinement. Sree Varahhas has executed several Reverse Engineering projects for various products to ensure that proper CAD models are created for handmade prototypes or existing samples.

Reverse Engineering Services

Get Price Quote

Determination of component product characteristics, dimensional measurements, materials testing, manufacturing process identification, drawing & specification development, prototype development, validation etc.

Reverse Engineering Services

500 - 5,000 Per no

1 no (MOQ)

3D Scanning, Reverse Engineering Services Creative Tools has rich experience of 3D Scanning, Reverse Engg, Class A Surfacing, Mold Flow, 3D Printing Services.

Reverse Engineering Services

Get Price Quote

Reverse Engineering

Get Price Quote

A growing number of clients are taking advantage of our full range of reverse engineering expertise which extends much further than simply the production of the pattern to include the actual casting, machining and shipping. The turnkey solution has also proved to be extremely attractive to clients in the prototype stage and by working closely together from the initial stage of design, our experts are able to save cost, avoid over engineering and ultimately reducing lead time from prototype to production.

Reverse Engineering Services

1,000 - 20,000 Per Unit

1 Piece (MOQ)

3D scanning for Reverse Engineering is a quick shortcut in the development process, as you receive a complete digital 3D model of your part in a very short time. In addition to forming the basis for CAD construction, the scanned data can be scaled, copied, and inverted. Kayra Global assists you in altering an existing Part design into an innovative Product Design as per your direct inputs.

Reverse Engineering Services

Get Price Quote

Are you on the lookout for a company that provides reliable Reverse Engineering Services in Ghaziabad? If your answer is a yes, we are the right choice to opt for. We have years of experience in machining component for aerospace industry and Defense Sector, which requires high degree of precision. Our team of diligent professionals uses the latest techniques and tools to render Reverse Engineering Services. Thousands of clients have benefitted by our Reverse Engineering Services and the next one could be you.

Reverse Engineering Services

Get Price Quote

Reverse engineering as the name suggests is to understand how a device work by deductive reasoning so that they can understand the components, software and other things in detail. This has been proved very useful in many businesses and a lot of companies are opting for it. We at Techinova Engineering Analysis Services LLP have been providing reverse engineering services to numerous clients since 2015 and have earned a name and reputation in the market. Our services are top-notch and we make sure that our clients are satisfied with them. What makes us different is that we understand your requirements and make sure to deliver them in the best possible manner.

Reverse Engineering Services

Get Price Quote

Reverse Engineering Services for a variety of components like plastics, aluminium, sheet metal, rubber, brass, die casting, etc are provided by us. Cad engineering services with a lot of heed to the trivia are proffered. Freeform imageware and I-DEAS software are used for 3D reverse engineering. Data so interpreted is used for the success of the client's project(s). Reverse engineering can be availed for any types of components such as : Plastics Rubber Brass Aluminum Sheet Metal Die casting