Single Roll Crushers

Get Price Quote

Being a reliable name in this arena, we make sure that the payment procedures remain secured with us. In addition, we issue invoice to the clients stating all the relevant information of the products. Our complete range of product is wrapped in strong, nontoxic, and superior-grade packs that protect the contents inside from damage, moisture, logistic movement, etc. Furthermore, the packaging has product details printed on it. Function Ajmani manufacturers the single roller crushes separate the field material with high pressure in the wedge-shaped crushing space between the toothed roller and the adjustable crushing balancer The driven toothed roller draws the material into the crushing gap. Due to the high impact rate of the circulating crushing tooth segments the effective crushing action starts already above the toothed roller. Design Welded robust housing Roller core shaped as a polygon with surface –ground supports for the crushing tooth segments. Locking of the segments by means of dovetail guides and fastening by screwed bolts Tooth shape and tooth pitch are adapted to the respective application Crushing tooth segments individually replaceable without lifting the crushing roller out. Crushing roller alternatively available with crushing rings. Crushing roller with dust-tighy encapsulated anti-friction bearing Stepless setting of crushing gap with optional mechanical or hydraulic overload protection Parallel evasion of crushing balancers on the occurrance of uncrushed components of the material Fields of application Cement, gypsum, and limestone Coal and Patash Mining Building, glass and chemical industries Metallugical plants Advantages Compact design Simple Maintenance High throughput Preserving crushing action Low undersize shares Scarcely any dust accurrence To enable our experienced engineering staff to recommend the installation best suited to specific applications,answers to as many of the following questions as possible will result in a prompt and accurate solution to your screening requirements Material to be crushed Maximum feed dimension Approximate feed size analysis Moisture content Stickiness Bulk Density Product sizes required Friability Abrasive Characteristics Do you intend close circuit operation Capacity desired in tons per hour

Roll Crusher

Get Price Quote

1 Piece (MOQ)

Ubh industries deal in high quality stone crushing plants and equipment and its spares to the entire satisfaction of our clients. Our products include jaw Crusher (Primary Crusher), Granulator (secondary crusher), roll crusher (bush type), belt conveyors and loaders in different sizes and designs according to the specifics requirements of customers. Our stone crushing plants range production from 20TPH to I50TPH according to the requirement of customer.Ubh industries always supplies replacement parts, as well as regular services to our customer crushing plants in most states of India, but enjoy strong equity in Sikkim, North Bengal, Bhutan, Nepal and Assam. stone crusher machine can be used in crushing of wide range of material such as BAUXITE, CARBORUNDUM, (Silicon Carbide), GRANITE, CALCUIM, IRON ORE, MANGANESE, RIVER GRAVEL, LIME STONE, BLACK ROCK, COAL, COKE, QUARTZ.Research and Development We under stand the fact that to survive the stiff market competition, it is imperative for us to constantly upgrade the technology used by us for manufacturing our material handling equipment. To help us in this, we have established a modern R&D unit within our organization, which is equipped with the latest technology based instruments and equipment. These help our R&D professionals in carrying out various research projects in an effective and competitive manner. After Sale ServicesWe provide efficient after sale services that is provided by our trained staff. We not only install the machines but also assist our clients with their first use. We ensure that our crusher's function properly and hence our team timely visits sites and attends to the complains, as well as provide timely servicing to the crushers. We also have in-store spare parts of each model and hence ensure perfect replacement of parts, if required. Parts List Main Body Liver Pin Jaw stock (Lever) Jaw Plates (Reversible) Toggle Bearing Toggle Plates Fixed Plate (Reversible) Slide Plate Fly wheel (Flat) Brackets cover Bearing Brackets Eccentric shaft Pitman fitted roll brg. Fly wheel (V-grove) Pull back rod Spring Washer Fly Nut Wedge block & Toggle Block

Best Deals from Roll Crusher

Roll Crusher

125,000 - 450,000 Per Piece

1 Piece(s) (MOQ)

We are offering roll crusher. the crusher is mounted on a very heavy base plate. The crusher is made of hardened alloy steel rollers. The rollers are fitted to a steel shaft and are mounted on heavy duty gun metal bearings. The drive is by a 3phase ,3 kw heavy duty motor with the help of v belts. A hopper is also provided for feeding the material in the crusher. size feed size discharge 4x8” 10mm 2mm and above 4x10” 12mm 2mm and above 6x10” 15mm 2mm and above

Roll Crusher

Get Price Quote

Details Most suitable machine for getting granules out of the brittle and hard material with very low fines generation. We offer a robustly constructed machine having roll with various metals like MS, En, SS, Mn Steel, etc. for better result & best life of wear & tear part. We offer roll with different design like tooth type (corrugated type) & plain type.

Roll Crusher

Get Price Quote

Double Roll Crusher

305,000 Per Set

1 Set (MOQ)

Double Roll Sand Crusher

850,000 Per Piece

1 Piece (MOQ)

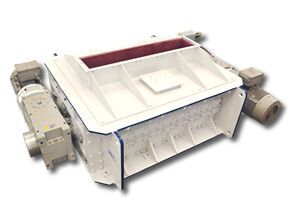

double roll crushers

Get Price Quote

ecoman is one of the principal industrial equipment manufacturer which has been making, selling and distributing, an array of high-end industrial machines especially the crushers of all types and profoundly the roll crushers to the indian and international markets. being widely accepted among the industrial applicators across the globe, with specific reference to industrial genres like metallurgy, building material, mining and energy our product range is inclusive of smooth double roll crushers, biomass and briquette crushers, and sinter crushers respectively. being the prime maker of double roll crushers, we believe in quality and fine performance. productive performance in the industrial machine making arena, we are best known for our powerful double roll crusher machines and here is an insight on them. double roll crushers the double roll crushers are strength wise great and best suitable for crushing any type of ores and rocks whose utility is more in chemical, mining and cement industries. prominent features of the double roll crushers reliable rolls perfect housing durable double motors distinguishing deep tooth gear decent double belts splendid safety spring facilitating the fertilizer industry with eminent crushers expanding into the fertilizer industry machine making, ecoman makes distinguishing biomass and briquette crushing equipment and also the double roll crusher machines which have a greater demand in sectors where fertilizers are to be used. hand pump for safety simple crushing rolls hydraulic adjustment maximum protection assurance through relief springs fixed on either of the sides ecoman has a widespread reputation for the kind of products it makes with exemplary design, inimitable performance and exclusive capacity, making the machines just unmatched products. With reliable and completely dependable product longevity coupled with error free working as well as hassle-free processing, ecoman stands as the best solution for all industrial equipment requirements.

Double Stage Roll Crusher

365,000 Per Piece

Double Roll Crusher

Get Price Quote

Roll Crusher

600,000 Per Set

1 Set(s) (MOQ)

Product Details: Minimum Order Quantity 1 Unit Roller Speed (r/min) 84 Drive Electric Capacity 30-120(t/h) The processing system of the double-toothed roller crusher makes it possible to crush any type of raw material from hard (limestone and rock) .

Double Roll Crusher

685,000 Per piece

1 piece (MOQ)

Roll Crusher

Get Price Quote

we are offering roll crusher in order to get the best results, material should be feed centrally into the valley formed by rolls, uniformly, continuously throughout the width of rolls, at a velocity very near to surface velocity of rolls. One roll is fixed and other roll is floating. Spring loaded in the case of overload or uncrushed coming into crushing zone and same roll can be moved closer or away to get the desired gap. Usually, these crushers will have teeth or raised forms on the face of the roll. Advantage: crushtech, double roll crusher gives a very fine product size distribution and they produce very little dust or fines. The roll surface is made of mn steel for heavy duty crushing. Rolls crushers are effectively used in minerals crushing where the ores are not too abrasive and they are also used in smaller scale production mining of more abrasive metal ores, application: grinding for quartz, salt, lime stone, marble chips, clinker & etc.

Roll Crusher

Get Price Quote

Royal Engineering is the prominent Manufacturer and Supplier of the Roll Crushers, which are precisely designed by the our skilled engineers to provide a helping hand in the varied industries & Quarries. To completely satisfy the clients, we make sure that our Roll Crushers do perform well in all adverse or non adverse conditions. Specifications : M.S. Steel fabricated bodyTwo MN Steel Rolls are provided moving in the opposite direction Two MN Steel Rolls mounted on two nos. shafts of adequate grade tested steelOne roll is mounted on the slide frameGap adjustment between two rollers is set for the different design requiredOne roll is spring loaded which provides safety precaution when non crushable material enters through the set of rollersMaterial grade of roller confirms to I.S.276 grade-II Fly wheels used are statically balanced Self aligning double cylindrical roller bearings sealed with labyrinths are recommendedSquirrel cage industrial motors drive is usedRoll crushers are bearings types & gear typesRoll crushers are double plain, double corrugated or single plain & single corrugated normal feed reduction ratio is 4:1 Applications : Railways Construction Sites Crushing Stone Zone

Smooth Roll Crusher

Get Price Quote

We are offering smooth roll crusher. With our cutting-edge technology, we make available to the esteemed clients smooth roll crushers. They are widely used for grinding process and results in less dust formation. The smooth roll crushers provided by us are widely acknowledged for their unmatched quality, reliable performance and easy functioning. used for crushing of : oresrock applications : mineral processing industrycement industrychemical industrybuilding material

Roll Crusher

1,000,000 Per Pack

Roll crusher is dust making machine That have various size for various production

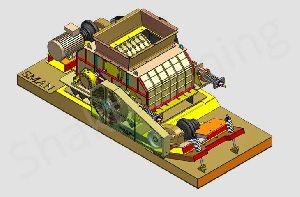

SMAN COAL DOUBLE ROLL CRUSHERS

Get Price Quote

COAL DOUBLE ROLL CRUSHER SMAN’s heavy-duty fabricated steel frame design, abrasion-resistant steel plate liners and easy-to-maintain parts means extended productive service. For maximum wear life, SMAN provides weld-on carbide teeth and can apply overlay hard facing to any applicable surface. Driven by electric motors and V-belts, all SMAN Roll Crushers have increased efficiency, high through-put for increased production and low roll speeds that minimize dust and fines. MAIN CUSTOMER BENEFITS OF DOUBLE ROLLER CRUSHER With the advanced hydraulic control system, users can adjust the pressure according to the material hardness, so that can press and pulverize the materials absolutely, with sensor, the machine can load relief when overload, so that to protect the machine; The advanced hard faced technology improves the roller Covers’ life, good performance, low cost in operation and easily maintenance. CONSTRUCTIONAL FEATURES Multistage gearbox 02 nos with fluid coupling. Double roll diameter = 1 mtr. Fitted with high manganese segment plates, which is easy for replacement. Shock impact absorbing double arrangement adjuster assembly. Heavy duty four spherical bearing with adjustment for opening in pedestal. Standard modular component easy to replace, Maintenance without any welding. This unit can be easily accommodated into any existing feeding & conveyor system.

PUZZOLANA roll crushers

Get Price Quote

PUZZOLANA roll crushers are mainly designed to handle medium to hard feed material. Toothed roll shells are used for primary crushing where as smooth roll shells are used for fine crushing. The crusher consists of base frame of welded construction with one roll fixed and the other roll mounted on rocker arms. These roll crushers are equipped with overload protection and a separate driver for each roll.

Roll Crusher

250,000 - 3,000,000 Per Nos

double roll crushers

Get Price Quote

We are the leading Biomass and briquette crushing machine manufacturers selling and distributing wide range of crusher worldwide. Our crushers are widely accepted across various industrial sectors like metallurgy, mining, building material, energy etc. Our product range includes – single and double toothed roll crushers, smooth double roll crushers, and sinter crushers.