Cooler Rotary

19 Per piece

300 Piece (MOQ)

rotary coolers equipment

25,000,000 Per Set

1 set (MOQ)

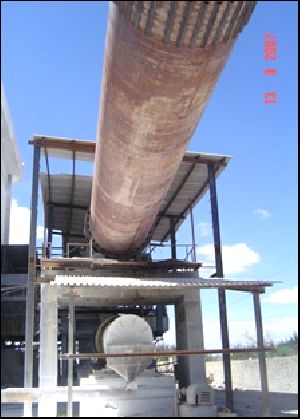

We are pleased to introduce Piyali Engineering Corporation, situated in Delhi, India. We are leading manufacturer and supplier specializing in the production of Sponge Plant DRI (Direct Reduced Iron) Rotary Kiln & Cooler equipment and vital components for steel plants, alongside catering to a diverse range of industries including sugar mills, cement plants, fertilizer plants, chemical plants, coal washeries, activated carbon plants, and ball mills. With a strong focus on quality and innovation, Piyali Engineering Corporation stands as a trusted provider of cutting-edge solutions across various industrial sectors. With a wide range of offers and a strong customer base, we have been serving the industry for several years. Our product range includes various capacities of DRI kilns and coolers, ranging from 50TPD to 600TPD & 900TPD, along with components such as support rollers, pinions, shafts, shells, combined bearing housing complete assemblies, spring plates, Ball Mill Pinion Shaft, Mill Head End Cover for Ball Mill Manufacturer, girth gears, and more. These offerings are designed to meet the needs of Cement Plants, Power Plants, Steel Plants, Sponge Iron Plants, Chemical Plants, Fertilizer Plants, and various other industries. Explore top-notch Lime Kiln Paper Mill Equipment at Piyali Engineering Corporation for customized, cost-effective solutions. Our commitment to excellence ensures reliable expertise and high-quality equipment, guaranteeing seamless industrial operations. Furthermore, we specialize in delivering high-quality Rotary Kiln & Cooler equipment specifically tailored for 350 TPD and 200 TPD DRI Sponge Iron Plant applications. We specialize in providing all the equipment necessary for your project, including Rotary Kilns and Coolers, ensuring your plant runs smoothly and efficiently. Trust Piyali Engineering Corporation, For superior engineering solutions. With us, you get the perfect fit for your plant's needs, ensuring smooth and efficient operations.

Best Deals from Rotary Cooler

Rotary Cooler

Get Price Quote

Overview: Fish Meal Cooler is used to cool down fish meal to room temperature. The main part of the cooler is made of carbon steel. Rotary cooler with internal rotar and external The driving is provided with suitable electric motor with chain drive.

Rotary Cooler

Get Price Quote

Rotary drums is a collective term and covers the following: ROTARY DRUMS – for drying, cooling, granulating, maturing, composting etc. ROTARY KILNS – for calcining, roasting, sintering etc. DRUMS OF SPECIAL DESIGNS – for indirect heat treatment such as drying and calcining.

Rotary Sand Cooler

Get Price Quote

ROTATORY DRYERS COOLERS

Get Price Quote

Ashoka one of the leading Rotary Dryers Coolers manufacturers In India, Rotary Dryer/Cooler is an industrial equipment engaged for drying or cooling of reasonably free flowing materials by introducing drying/cooling media directly onto the processing material. Material to be dried or cooled goes through the dryer, and as the dryer rotates, the material is raised up through a sequence of inner fins lining fixed on the interior wall of the dryer. These dryers are available with customization based on different parameters and are available in a number of configurations and specifications. There are two categories of such equipment which are: Direct Heaters/Coolers and Indirect Heaters/Coolers. These rotary dryers/coolers are featured with a rotating shell, which acts as stirrer and conveying device.

ROTARY Drum Sand Cooler

Get Price Quote

The almost ZERO maintenance equipment for cooling HOT return sand after Shake-out for small-medium-large foundries. BMM make ROTARY Drum Sand Cooler is the most efficient & serving successfully to the foundry industry from many decades. Its robust & durable construction helps the foundries to go on using for years to come without any break down. It also helps in homogenous the sand during the transit inside the drum chamber.

Rotary Atomizer Type Spray Coolers

Get Price Quote

We offer rotary atomizer type spray coolers. Rotary atomizer type spray coolers is defined as a process by which a melt is formed into particles of spherical shape by spraying the melt into a cooling chamber through which ambient or cooled, low temperature air is passing.

Rotary Cooler

Get Price Quote

Rotary Cooling is used for compound fertilizer production, cooling certain temperature and particle size of fertilizer, matched with drying machines. Can greatly improve the cooling rate, reduce labor intensity and improve production. Further removal of part of the water the reduce fertilizer grain temperature. At the same time it also can be used for other powdery, granular materials cooling, rotary cooler is the main matched machine in rotary kiln production system, its structure is simple, good stable performance, reliable operation. The exhaust gas may be introduced into the rotary kiln after heat exchange, thereby improved the thermal efficiency of the entire system.

Rotary Cooler

Get Price Quote

ROTARY COOLER is a part of Rotary kiln system used to lower the temperature of the hot products discharged from the kiln to a temperature approaching ambient. The Rotary Cooler is installed beneath the Rotary Kiln and interconnected with the kiln discharge hood. The construction is similar to Rotary kiln with a cylindrical shell inclined to the horizontal with tyres, support rollers, feed hood and driven by girth gear & pinion. A part of the cooler shell is castable lined to take care of the shell from the hot discharge.The Rotary Cooler operates in counter-flow, the hot gases being substituted by ambient or chilled air, which is in direct contact with the hot material. For high temperature applications the material is cooled to a temperature approaching ambient by continuous water spray over the shell and operates on the principle of heat transfer through the rotating cylinder wall which is continuously irrigated by a series of external water sprays mounted over the unit. The water is partially evaporated as steam while the excess is collected from the bottom of the unit and re-circulated. The material thus cooled is discharged from the other end of the shell.

Rotary Sand Cooler

Get Price Quote

Rotary Cooler

Get Price Quote

long lasting and consistent performance Rotary coolers from SAKA are known for their long lasting and consistent performance. SAKA has built a strong capability to design and develop customised Rotary Coolers as per specific requirement. Whether you require short or long residence times, chilled or ambient cooling air, carbon steel or specialty steels, we can design a Rotary Cooler for your application and analyze its performance well before manufacturing. Rotary Coolers have heavy-duty drum construction. This makes it ideal for wide range of applications and large capacity processing for both drying and cooling procedures. Typically, Rotary Coolers work on the principle of counter current air flow where chilled or ambient air comes first in contact with material at its highest temperature leading to efficiently cooling. Additionally, flights lift and cascade material through the drum, enhance the cooling process.

rotary coolers

Get Price Quote

rotary coolers, anode furnaces, Rotary Kilns, rotary granulator

Rotary Cooler

Get Price Quote

Rotary Cooler, boiling house equipment, Ball Mills, jaw crushes

Rotary Cooler

Get Price Quote

Rotary Cooler, Wet High Intensity Magnetic Separator, wet grinding mill

Rotary Sand Coolers

Get Price Quote

Rotary Sand Coolers, fettling equipment, Transfer Molding Press

Rotary Kiln Cooler

Get Price Quote

Rotary Kiln Cooler

Monohydrate Rotary Cooler

Get Price Quote

Monohydrate Rotary Cooler, chemical process equipments, Pier Cap Shutter

Rotary Cooler

Get Price Quote

Rotary Cooler, Foundry Ladles, Bottom Pouring Ladle, Shake Out Machine

rotary coolers

Get Price Quote

rotary coolers, Micronizing Plant, Vertical Shaft Kiln