-1723619676-7564500.jpeg)

Endox (Rotary files)

1,350 - 1,600 Per Piece

100 Piece (MOQ)

Nickle Titanium rotary file is used to prepare and shape root canals to apex. Its innovative curtting edges blades and cross section shape enables flexible passage along root canals. The design of flute and edges allows file to grate and control cut of root canal. Excellent heat induced flexibility ensures easy passge along even most difficult root canals Features: Sharp and styled cutting edge Abrasive property allow smooth shape. Axial and torsional high flexibility Efficient cutting along length to tip Benefits Safe and easy technique Donot screw effect Quality metal Economical in use. Sold a pack of 6 Assorted sizes

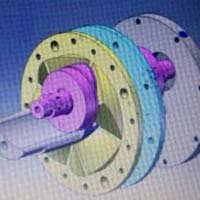

rotary internal combustion engine

Get Price Quote

Another variety that we bring to our global buyers is Rotary Internal Combustion Engine. Designed and manufactured in accordance with industry standards and market demands, our Rotary Internal Combustion Engines are of unmatched standards. We manage a large stock at our storage facility to meet voluminous orders anytime. Buyers can get Rotary 32d Variable Volume Internal Combustion Engine at modest prices from us.

Best Deals from Rotary Engines

Rotary Breaker

9,500,000 Per set

1 Set (MOQ)

We are pleased to introduce Piyali Engineering Corporation, located in Delhi, India. We are leading manufacturer and supplier specializing in the production of Sponge Plant DRI (Direct Reduced Iron) equipment and vital components for steel plants, alongside catering to a diverse range of industries including sugar mills, cement plants, fertilizer plants, chemical plants, coal washeries, activated carbon plants, and ball mills. With a strong focus on quality and innovation, Piyali Engineering Corporation stands as a trusted provider of cutting-edge solutions across various industrial sectors. With a wide range of offers and a strong customer base, we have been serving the industry for several years. Our product range includes various capacities of DRI kilns and coolers, ranging from 50TPD to 600TPD & 900TPD, along with components such as support rollers, pinions, shafts, shells, combined bearing housing complete assemblies, spring plates, Ball Mill Pinion Shaft, Mill Head End Cover for Ball Mill Manufacturer, girth gears, and more. These offerings are designed to meet the needs of Cement Plants, Power Plants, Steel Plants, Sponge Iron Plants, Chemical Plants, Fertilizer Plants, and various other industries. Explore top-notch Lime Kiln Paper Mill Equipment at Piyali Engineering Corporation for customized, cost-effective solutions. Our commitment to excellence ensures reliable expertise and high-quality equipment, guaranteeing seamless Paper Mill operations. Specializing in Rotary Pulp Dryers, Mineral Slag Rotary Drum Dryer we provide comprehensive solutions for your paper manufacturing needs. At Piyali Engineering Corporation, we prioritize quality and strive to deliver products that meet and exceed customer expectations. Our adept and seasoned team is deeply committed to providing unparalleled service and ensuring utmost customer satisfaction. Furthermore, we are proud to introduce our top-notch equipment for Coal Washery Rotary Breaker Dryer Drum, Kiln Tyre, Support Roller, Chain & Sprockets, Guide Roller, and Fabrication services and more. Our dedication to providing customized, cost-effective solutions remains unparalleled, ensuring seamless operations for Coal Washery plant. For any inquiries or further information, please do not hesitate to get in touch with us via the provided contact details: PIYALI ENGINEERING CORPORATION Contact Person: Ranjan Kumar Phone: +91 798-239-8797 Email: sales@piyaligroup.com. Thank you for your consideration.

POWER WEEDER BACK ROTARY 9 hp diesel Engine AG11-BC9

Get Price Quote

With our brilliant logistics network, we are capable to deliver the orders within the postulated time frame. Located in Mumbai(India), our company is involved in making available wide array of products that are in conformance with the industry standards.

rotary wing engine

Get Price Quote

Philadelphia: As part of the Boeing India Media tour 2012, FORCE was invited to visit the company’s rotary wing production facilities at its ‘Mobility’ headquarters in Philadelphia. It is here where the revolutionary Bell Boeing V-22 ‘Osprey’ tiltrotor and CH-47 Chinook tandem rotor, medium-lift helicopter are built. This year, the Chinook celebrated 50th anniversary of the 1st CH-47 Delivery (A model) to the Indian Army. The other place visited was Boeing’s Mesa, Arizona facility where the AH-64D Apache Longbow is produced. The AH-64D Apache Block III has already been selected as the winner of the Indian Air Force’s (IAF) requirement for 22 next generation attack helicopters and the CH-47 Chinook is in the running for 15 heavy-lift helicopters for the IAF. Keeping this in mind, the visit was an exciting opportunity to meet with the teams who build these helicopters and also take a look at the production facilities.

Wing Divider

200 - 500 Per Piece

1000 Piece(s) (MOQ)

Wing Divider, spring calliper, Spring Divider Caliper, Brass divider set

rotary wing engine

Get Price Quote

rotary wing engine, Bullet Proof Helmets, Laser Range Finder

rotary engine

Get Price Quote

rotary engine, Blowers, Marine Chilling Compressor