Automatic Roto Moulding Machine

350,000 Per piece

1 piece (MOQ)

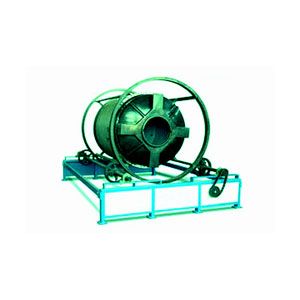

Rock-N-Roll Rotomolding Machines

Get Price Quote

The Rotomoulding Plant with Rock & Roll machine� Series BS is composed of Heavy Duty Moulding Chamber with multiple burners placed strategically at bottom with Separate cooling station with high velocity cooling fans with Fogheads & Control Electric Panel. Salient Features Sturdy machine suitable for manufacturing large size hollow products up to 40,000 ltrs or more Less investment, high production machine Multiple layer product can be made on this machine. Speed variable drive for better Rocking & Rolling for better control of the product

Best Deals from Rotomolding Machine

Roto Moulding Extruder

Get Price Quote

rotomolding machines

Get Price Quote

Rotomoulding machines are specially designed to hold large moulds as well as multiple moulds with various capacities. Provision for such large mould carrier plates and arms are provided for both side support for sturdy and comfortable operation instead of cantilever type station arms which is a special feature for the shuttle type machines.

Closed Oven Rotomolding machine

680,000 - 750,000 Per Piece

1 Piece (MOQ)

This NP Rotoplast closed oven RNR fully automatic machine is widely accepted by the market for it’s more productive, fuel efficient, energy-saving and cost-effectiveness. It has a closed oven thus making production more Economical, Easy mould mounting arrangement makes it flexible and improving the efficiency by 30% compared with other models. High utilization rate of oven makes machine more energy-saving and environment friendly; This is most suitable for simultaneous production of medium to large size products with similar moulding time. Features of closed oven rotomoulding machine : Optimum oven design leads to low gas consumption & Environment friendly More production/cycle due to multi moulds mounting arrangements Sufficient oven wall thickness to withstand working temperature 250 degree Celsius Bestselling machine for small & Medium scale business Best suitable for 50L to 20,000L water storage tanks Also suitable for small & Medium size of articles. Four windows given in door for 2nd,3rd charging to make multi-layer tanks easily For single mounting mould, material can be feed from screw Oven rocking & Door open close movement powered by Hydraulics Fully automatic Rolling & Rocking motion Auto ignition for burners for quick start PLC Automation (on request) Microprocessor based machine control with digital display (on request)

Electric Rotomolding Machines

1,250,000 Per Piece

OPEN FLAME ROCK N ROLL ROTOMOLDING MACHINE

Get Price Quote

Owing to our state-of-art manufacturing unit and the usage of leading-edge techniques, we are able to present a comprehensive range of Flame Rock N Roll Machine.

Rotomolding Rotational Moulding Machine

560,000 Per Piece

1 Piece (MOQ)

rotomolding machines

Get Price Quote

The machine is Easy To Operate, Low Maintenance and Minimum Manpower required to operate. The Ultimate Machine products Large Size Hollow Tanks. Less Installation Cost and Easy Operating System with Control Panel. Machine Available upto 40000 Litres capacity tank Products.

Rotomolding Rotational Moulding Machine

Get Price Quote

Single station bi-axial machine model en-3000 highly suitable for making tanks and products from 1000 to 3000 lit size.

rotomolding machines

Get Price Quote

Rotomolding machines re-evaluation of our machines in respect of their performance and operation and keep upgrading them with the latest technological inputs. We have been provider of high performance & cost effective Roto Moulding Solutions to meet the exact needs of our valued customers.

Rotomolding Rotational Moulding Machine

300,000 Per Piece

Rotomolding Rotational Moulding Machine

3,500,000 Per Piece

1 Piece (MOQ)

Rotomolding Rotational Moulding Machine

Get Price Quote

Vinodrai Offers Range of standard as well as customized moulds for water storage tanks, household products & Industrial Products. We offer sheet metal moulds, steel CNC machined moulds & Cast Aluminum moulds as per need of customer.

rotomolding machines

Get Price Quote

FixoPlus Range of Rotational Molding Machine is a modular, highly aerodynamic, independent indexing, multi-arm indirectly fired rotomolding machine, with a number of features like injection for transvectors; and controls using HMI Interface with a PLC, featuring individual mold recipes, visual audio alarm, maintenance programs, and a hoard of safety interlocks and other features. FixoPlus is a highly efficient rotomoulding machines and gives even heat distribution with a very high hot air recirculation, using minimum power and fuel. FixoPlus Rotomolding Machine is versatile for producing any kind of simple or complex Rotomolding parts e.g. tanks. Automotive products like bull bars, roof racks, bumpers, etc., planters, garden furniture, mannequins, medical equipments surgical units, toys like rocker, slide, baby pool, school bench and many more.

rotomolding machines

Get Price Quote

Rotomolding machines such heavy mould carrier plates and arms are provided both side support for sturdy comfortable operation instead of cantilever type station arms, which is a special feature for the shuttle type machines

Rotomolding Machine

Get Price Quote

We manufacture Rotomolding Machine, which is widely recognized for its high performance. The best attribute of our Rotomolding Machine is that it functions with minimal assimilation associated with fuel energy in addition to electrical energy. We are a preferred name among the Manufacturers of Rotomolding Machine as we are 100% devoted to accomplish our aim of providing high quality Rotomolding Machine as per the specific client’s requirements. Highlights : Low maintenanceHighly versatileEasy InstallationHighly durable.

rotomolding machines

Get Price Quote

Plastic Powder is placed in a metal mould. Mould is slowly rotated in two directions (Biaxially) inside the heating chamber. Powder melts and forms a uniform coating on the inside surface of mould. The rotating mould is then cooled in open air or in a cooling chamber and plpastic solidifies to mould's shape. Mould is then opened and product is removed.

Single Station Rotomolding Machine

105,000 Per

1 Piece (MOQ)

Carousal Rotomolding Machine

Get Price Quote

FixoTron Range of Rotational Molding Machine – the classical rotomolding machine and a type of which maximum numbers are used and sold worldwide. FixoTron is an independent indexing, multi-arm, indirectly fired, independent indexing hot air recirculating rotomolding machine with controls using MMI Interface with a PLC, featuring individual mold recipes, maintenance programs, and a hoard of other features. FixoPlus is a highly efficient machine and gives even heat distribution with a very good hot air recirculation, using minimum power and fuel. The control panels conform to IEC standards. This machine is a fast and efficient machine that uses minimal labor.