cassava press

39,000 - 40,000 Per piece

.`nans’ brand cassava (pulp) dewatering screw press screw press (hand operated)capacity 50 – 300 kgs / hour

Copra Screw Oil press

Get Price Quote

1 piece (MOQ)

Best Deals from Screw Press

Biogas Slurry Dewatering Screw Press Machine

Get Price Quote

1 piece (MOQ)

down stroke friction screw press

900,000 Per Piece

1 Piece (MOQ)

Stainless Steel Multi Disc Screw Press Machine

200,000 - 1,200,000 Per piece

1 piece (MOQ)

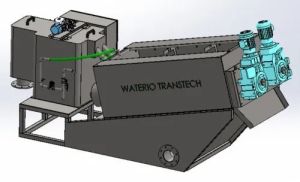

Dewatering Screw Press Machine

250,000 Per piece

1 piece (MOQ)

Solids dewatering screw press, useful for dewatering solids to be discharged.

PP Screw Type Filter Press

Get Price Quote

We effortlessly dispatch the product basket to the clientele as we have excellent, wide connectivity and trusted shipping facilities. With our streamlined packaging system, we are capable of meeting standard as well as tailored packaging needs of the patrons. And, we make use of premium material for packaging.

Semi Automatic Dewatering Screw Press Machine

450,000 Per Piece

1 Piece (MOQ)

Multi Disc Screw Press

215,000 - 850,000 Per piece

1 Piece (MOQ)

Mild Steel Dewatering Screw Press

45,000 Per Unit

1 Unit (MOQ)

Screw Press

290,000 Per piece

1 Piece (MOQ)

Multi Plate Screw Press

Get Price Quote

Pollucon Engineering Services promotes the Multi-Plate Screw Press of Techase (World leader in Solid Liquid Separation) which consumes very less power comparison to other sludge dewatering devices. Details : Sizes Available: 3 Kg/ hr – 600 Kg/ hr dry sludge output Special Features : Very Low Power Consumption, Self Cleaning, Clogging Free, Fully Automatic Applications : Water/ Wastewater Treatment System

Friction Screw Press

Get Price Quote

Screw Press Dewatering/Juicing Machine

500,000 - 5,000,000 Per Piece

01 Piece(s) (MOQ)

Intro: The screw press is a device that uses physical extrusion to dewater the device. The device includes driven System, feed box, spiral auger, screen, pneumatic material blocking device, sump, rack, etc. The material enters into the equipment from the feeding box and is subjected to progressive pressure extrusion under the conveying of the spiral auger. Excess water is discharged from the liquid outlet through the screen, and the moisture-removing material is continuously transported by the spiral auger. The top opening and blocking device is discharged from the discharge port by the discharge port. It is truly low energy consumption, high output, low moisture, and secondary circulation for material to save a lot of processing costs. Working principle: The dewatering process of the screw press dewatering machine is divided into two stages. The first stage uses the screw auger to dehydrate. The spiral auger has three sections: the transmission section, the compression section and the discharge section, and the transmission space become smaller gradually to press the materials stronger and make the material extruded water. The second stage uses a material-blocking device to dewater. When the material enters into the discharge section of spiral auger, the spiral auger applies axial thrust to the material to push it out of the discharge port, while the pressure device is pressurized by the pneumatic device which applies a reverse force to the material to be pushed out, thereby forming a pressing force to the material to realize the dehydration.

Dewatering Screw Press Machine

500,000 - 5,000,000 Per pc

Corn Germ Dewatering Screw Press

Get Price Quote

1 Piece(s) (MOQ)

We offer our clients an optimum quality range of Corn Germ Dewatering Screw Presses which are manufactured using the best grade basic material and superior technology in synchronization with the set industry standards. Owing to their robust construction and easy maintenance, these screw presses are widely demanded among our clients. Furthermore, to ensure the best quality, the provided screw presses are properly tested by our quality controllers on various parameters. These and any other specific requirements will dictate the design. Some of the aspects determined are: Few essential parameters for design are: Material to be processed: Moisture specification - Inlet and Final Moisture. Capacity - Feeding Capacity of wet material in an hour. Production quantity required-03 to 60 TPD.(Fiber) Number of screws - Single or Twin. Type of Control - Adjusting Cone Fitted With Pneumatic System. Length, Diameter and Compression of the Screws: Type of screws - Conical. Type of screen - Perforated. Reinforcement of screens with support caging: Material used in entire parts of the construction - Mild Steel or Stainless Steel.

Aqua System Screw Press

Get Price Quote

Sn Aqua System Screw Press is designed to separate liquids from solids. A screw press can be used in place of a belt press, centrifuge, or filter paper. It is a simple, slow moving device that accomplishes dewatering by continuous gravitational drainage. Screw presses are often used for materials that are difficult to press, for example those that tend to pack together. The screw press squeezes the material against a screen or filter and the liquid is collected through the screen for collection and use. Screw filter press body of volute sludge dehydrator consists of multiple fixed and floating plates and volute filter, which is able to complete the sludge thickening and squeeze dewatering in one cylinder with organic combination of technology of thickening and pressing. Product Application: City mixed raw sewages Food & beverages industry Chemical industry Stone & mine sewage Leather & tannery sewage Paper & pulp sewage Electro plating sewage Printing & dyeing Sewage Power plant Petrochemical industry Product Features: Suitable for sludge treatment of high/low c=consistency. When dealt with sludge of low consistency (2000mg/l), there is no need to build a thickening tank and storage pool. Thus reduce the cost and build a thickening tank and storage pool, thus reduce the cost and the release of phosphorus and anaerobic stink. There is no need to worry about jam up. Thus reduce the cleaning water consumption. The electrical cabinet, disposal tank and dehydrator are integrated which reduce the covering area and brings convenience to installment. Automatically working for 24 hours, reducing the labor strength of workers. It is made with stainless, extending the service life, It is convenient for daily maintenance.

Screw Press

Get Price Quote

Screw Press

Get Price Quote

1 Piece (MOQ)

Dewatering Screw Press Machine

Get Price Quote