Side Seam Welder

Get Price Quote

Type : Container Side Seam Welder Standard Ratings : 10 KVA to 15 KVA Features: Specially designed damping cylinder with fully pneumatic operation ensures reliability without troublesome oil leakage problems. Antifriction recirculating ball type carriage guide ensures smooth carriage movement and long trouble free operation requiring negligible maintenance. Wire Tensioning system ensures constant wire tension possible on conventional spring loading tension possible on conventional spring loaded tensioning devices. Specially designed overide coupling provided on wire drive pulley allows smooth take up of wire stretch which is not possible on paul and rachet type free wheels. Electromagnetic clutch break system used on wire drive has faster response time thereby giving large production volume per shift while requiring negligible maintenance. Fully solid state control system provided reliability and long life. Machine provided with electromagnetic counter to record total quantity of cans produced. Application : Used to weld the Side Seam of metal containers produced with tin plate, edge ground TFS and stainless steel.

Long Seam Welder

120,000 Per Piece

Best Deals from Seam Welder

Seam Welder

Get Price Quote

Longitudinal Seam Welding Universal Seam Welding Circumferential Seam Welding Side Seam Welding Narrow Track Seam Welding Options Knurled dressing wheel for Electrodes Electrode Drive - Top, Bottom or Differential

Side Seam Welders

Get Price Quote

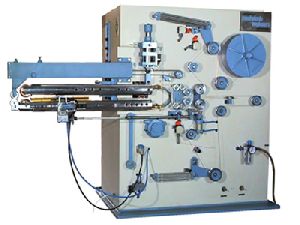

MECHELONIC ENGINEERS Container Side Seam Welding Machine model 18-51 is a trustworthy and economic way of producing consistent, faultless and narrow weld at highest working speeds eliminating need of skilled operator. Weldability:The machine is capable of welding a wide range of materials, Tin sheets, Black and TFS sheets (after proper edge cleaning) with thickness ranging from 0.2 to 0.4 mm and body diameters ranging from 52 to 300 mm and body height upto 450 mm depending on the lower arm size. Intermediate Electrode:Use of electrolytic copper wire as an intermediate electrode between weld wheel and tin sheet, avoids deposition of molten tin on weld wheels and ensures consistent, quality weld without frequent cleaning of wheels. Welding Arms:Upper arm made out of high tensile brass is common for complete range of can diameters and is actuated by a hydropneumatic-damping cylinder to avoid initial impact on contact with lower weld wheel and to maintain constant welding force. Lower arm is complete with carriage guide rail, Z-bar, weld wheel etc. Three standard sizes of lower arms are available. Any one size of arm will be provided with machine, other sizes will be available at extra cost. Weld whels & Z-bars:Antifriction, mercury contact weld wheels made out of special copper alloy & Z-bars made out of wear resistant material are available in three standard sizes i.e. 52, 65 and 100 size suitable for respective arms. These wears out parts are available as spares off the shelf. Standard overlap provided on Z-bar is 4 mm. Carriage:Carriage assembly with built-in pneumatic clamping and limit switches for low/high current initiation, auto cut off and frame contract is mounted on antifriction bearings and can be adjusted for different can lengths easily. Different sizes of carriages are available to match each size of arm. Movement of carriage is actuated by automatic fly-start system to maintain normal welding speed from the start. Electronic Control: High precision fully solid state welder control incorporating thyristors permits uniform weld quality. Two-stage heat control unit controls the intensity of weld current at the beginning of weld cycle at desired low levels. Current control is through transformer taps and potentiometers. Operation and work cycle: Once the welding parameters like current, pressure, speed, carriage positioning, high /low heat and cut-off limit switch setting is over, operator must feed a pre-rolled sheet into the carriage and Z-bar, pushing it lightly against frame contact actuators. On actuation of frame contact limit switches all further operations take place automatically. Rolled body is clamped at the rear with pneumatic clamps. Upper welding roller comes down making contract with lower weld wheel and welding pressure is developed between wheels by hydropneumatic clamping cylinder and spring. Once the correct welding force is generated, the switch fitted on cylinder actuates wire feed system. The carriage is pushed forward at the start of operation by means of fly-start mechanism. Initially reduced current is applied for a pre-determined length and thereafter-full welding current is provided. The weld initiation with reduced current and change over to full current is done automatically by welder control. At the end of weld, the current is cut-off, wire, feed system stops and upper weld wheel goes up automatically. The job can be taken out after clamps are released and carriage is pulled back by spring balancer making machine ready for next cycle. Provision is also made for foot switch initiation in place of frame contact to initiate weld cycle. Easy Maintenance:Open side mounting of weld wheels, with easy accessibility to every working part along with use of highly reliable, high quality parts like solenoid valves, bearing, weld wheels, etc. reduce the need and frequency of maintenance. A class 'F' insulated welding transformer and other specially built assemblies like drive unit, wire reservoir, control system allow 24 hour continuous operation of machine. Service Facilities: (to be provided by customer) Compresses Air:Minimum pressure 5.6 Kg./cm sq. Cooling Water: 10 LPM @ 3 kg/cm sq. pressure and 18 degrees C for welding arm cooling. 10 LPM @ 3 kg/cm sq. pressure and 30 degrees C for thyristor cooling

longitudinal seam welder

Get Price Quote

We are dedicatedly betrothed in offering a commendable array of Long Seamer. Our offered long seamers are manufactured with leading techniques utilizing best material under the direction of our experts. Along with that, this long seamer can be customized as per the need of customers within a committed time frame. This long seamer is tested on various parameters in order to make certain its flawlessness.

Circumferential Seam Welder

Get Price Quote

Heavy Duty, thyristor controlled electronic timer with electronic heat regulation, to give stepless alteration of welding speed process, reduce welding costs and improve the quality of the weld Fan cooled transformer having cold wire feed and high grade silicon steel Application drive shafts establish nonslip drive Efficient cooling system results least use of the electrode wheels Structures with solid and sturdy base frames for least impact load Leakage proof joints at much lower costs, than conventional welding

seam welders

Get Price Quote

Seam welding is resistance welding or roller welding process for joining metal sheets seam joints between two rotating electrode wheels performed using electrical current which is passed through a lid and container. As the metal heats up, the lid is completely joined to the body of the container. Seam Welding is high speed and clean process, which is used when continuous tight weld is required. Seam Welding is mainly used on the seams of tubes and pipes for its ease and accuracy. Seam welding is used to create larger flat-stock parts, join relatively long components, and create cylinders, cones etc.

Universal Type Seam Welder

Get Price Quote

Frequency Inverter Seam Welder

Get Price Quote

JANDA’s DC Inverter with constant power and current control ensures high quality welds on aluminum alloys and stainless steels. Features: Three phase high frequency inverter power supply operates at 1200 hz with primary and secondary constant current Fully rectified DC secondary – virtually no secondary inductive loss Built-in weld checker simultaneously monitors current, voltage, power, welding time and detects problems Heavy-duty reinforced frame’s withstand heavy pressures required for certifications Compact design allows for full three phase power in a single phase frame size Upper weld head adjusts left-right Lower weld head adjusts left-right thru T-slot & moves up-down up to 6” for different wheel diameters Lower or upper head drive with SCR speed control Internally water-cooled weld shafts Camrol guided ram Optional Tip Dress & Forge , Retraction, Adjustable Weld Stroke, Dual Drive

Seam Welder

Get Price Quote

Seem Welders are used in Rim, Silencer and Fuel Tank Manufacturing units. Product Specification Item Unit SMY-100 Rated Supply V 400 ± 10% Phase Ph 2 Frequency Hz. 50 Load KVA 100 Welding Current A 17,000 Standard Stroke mm. 100

seam welders

Get Price Quote

We are offering seam welders. Longitudinal, circumferential and universal seam welders and of rating 50-250 kva (single phase ac or three phase dc)

Seam Welder

Get Price Quote

Thyristor controlled electronic timer with electronic heat control, to give heavy duty high speed operation, providing smooth, stepless and accurate adjustment of the welding current. High quality roller bearings carrying the roller shafts, guaranteed longer-life of the roller heads. Leak proof joints at much lower costs than conventional welding.

Dual Head Seam Rim Welder

Get Price Quote

Basic Features Silver Bearings for Electrode Heads - Better Electrical Conductivity Stroke Adjustable Welding Cylinder - Electrode Gapsetting Easy to use Digital Controller - Consistent Weld Quality

Container Side Seam Welder

Get Price Quote

This welding machine is for tin sheets, black sheets and tin free sheets equipped with wire feed system, and one complete set of arm assembly consisting of z-bar , saddle, forming rollers etc. fully solid state thyristor weld control

Seam Welder

Get Price Quote

Machines offered are single phase AC for seam welding of Drums and Barrels, Fuel Tanks, Silencer, Muffler, Shock Absorber etc. SPMs are offered for applications such as fully automatic barrel and shell welding, tub welding, fuel tank welding etc. We also offer 3 phase, DC machines with matching controls for special applications. Standard Rating KVA : (@50% duty cycle) 50,75,100,200 & above on request

Seam Welder

Get Price Quote

The Mechelonic Seam welding machines are precision built and of robust construction suitable for a long and trouble free production. It is used for leak tight assemblies for petrol tank, shock absorbers, oil barrels and shells of can, etc. The seam welders are available for longitudinal, horizontal and universal welding requirements. Features: Heavy-duty frame Air preparation system Water-cooled wheels Low inertia- anti-friction ram Internal and external cooling feature Varying forms of Electrode drive systems AC or DC current Water-cooled secondary Welding Transformer Single-Phase AC 3 phase DC option Core is high grade steel IS-4804 Class “F” insulation Impregnated and tropicalized Mid-Frequency Inverter DC option Air-Cooled Welding Control Micro-processor Precision Weld settings Upslope/Downslope Solid-state water cooled Adjustable weld time settings Constant current feature Pulsation Quench and Temper

Universal Seam Welder

Get Price Quote

Side Seam Welder

300,000 Per Piece

Seam Welder

Get Price Quote

seam welding machine offers to weld the last side of the radiator automatically . The machine is programmed to weld both the ends of the raditors which is sutibale of any length of radiator.

Seam Welder

Get Price Quote

Mipalloy seam welder wheels are the benchmark for quality in the industry. We manufacture forged & fully heat treated seam welder wheels in Mipalloy 3ZR. Wheels are made in varying thickness from 2” diameter to 28” diameter in proof machined condition or fully machined ready to use. Mipalloy wheels guarantee higher hardness & electrical conductivity resulting in superior performance. Most common sizes are available off the shelf. Most sizes considered non standard are surprisingly available off the shelf at Mipalloy.