Temperature Sensors

Get Price Quote

We deal in wide range of Temperature Sensors. Right from RTD Sensors and Flexible Thermocouple Wire Sensors, we make available all types of Temperature Sensors. We have updated fabrication facility to come up with Temperature Sensors in different technical specifications. All the accessories are specifically tested for resistance to corrosion, moisture and likewise climatic conditions. Also, they comply with ANSI standards. We believe in offering the best value for money and this makes us a sought-after name as Temperature Sensors Manufacturer, Exporter and Supplier from Haryana. What are the different thermocouple types?A thermocouple is available in different combinations of metals. The four most common calibrations are J, K, T and E. There are high temperature calibrations R, S, and B. Each calibration has a different temperature range and environment, although the maximum temperature varies with the diameter of the wire used in the thermocouple. Although the thermocouple calibration dictates the temperature range, the maximum range is also limited by the diameter of the thermocouple wire. That is, a very thin thermocouple may not reach the full temperature range. How to select a thermocouple type? Because a thermocouple measures in wide temperature ranges and can be relatively rugged, thermocouples are very often used in industry. The following criteria are used in selecting a thermocouple : Temperature range Chemical resistance of the thermocouple or sheath material Installation requirements (may need to be compatible with existing equipment; existing holes may determine probe diameter) How to select a junction type? Sheathed thermocouple probes are available with one of three junction types; grounded, ungrounded or exposed. At the tip of a grounded junction probe, the thermocouple wires are physically attached to the inside of the probe wall. This results in good heat transfer from the outside, through the probe wall to the thermocouple junction. In an ungrounded probe, the thermocouple junction is detached from the probe wall. Response time is slower than the grounded style, but the ungrounded offers electrical isolation. Thermocouple in the exposed junction style protrudes out of the tip of the sheath and is exposed to the surrounding environment. This type offers the best response time, but is limited in use to dry, non-corrosive and non-pressurized applications. Types : A grounded junction is recommended for the measurement of static or flowing corrosive gas and liquid temperatures and for high-pressure applications. The junction of a grounded thermocouple is welded to the protective sheath, giving faster response than the ungrounded junction type. An ungrounded junction is recommended for measurements in corrosive environments where it is desirable to have the thermocouple electronically isolated from and shielded by the sheath. The welded wire thermocouple is physically insulated from the thermocouple sheath by MgO powder (soft). An exposed junction is recommended for the measurement of static or flowing non-corrosive gas temperatures where fast response time is required. The junction extends beyond the protective metallic sheath to give accurate fast response. The sheath insulation is sealed where the junction extends to prevent penetration of moisture or gas which could cause errors. Factors to Consider : Choosing the correct thermocouple requires that you look at a number of factors. For example, a thermocouple, which is used only periodically, may be less expensive, but it may have a shorter life span and require servicing more often. If the thermocouple is intended to be used for long periods without service, it may be necessary to use a thicker gauge of wire and it may be necessary to use a design engineered for a greater degree of protection. Below are some general guidelines to consider when choosing a thermocouple. If you need more help making a decision our knowledgeable sales staff is available to recommend a design which will best suit your application. What are the maximum and minimum temperatures the thermocouple will see? What error tolerances are necessary for your application? What is the Measuring atmosphere?(Corrosive/abrasive/vibrating etc) What is the time response required? Will the thermocouple be used continuously or periodically? Will the thermocouple see bending or flexing during it's life? What is the immersion depth? General Guidelines : Do not allow excessive bending of the thermocouples. Cold working can lower the insulation resistance at certain points causing short circuits or decreased accuracy. Use protection tubes for corrosive atmospheres Always inspect protection tubes when changing thermocouples. Things to look for include cracks, pinholes, contamination, or discoloration. Do not locate the thermocouple too close to a heating element Record the life span and cause of failure for each thermocouple to help track down potential problems. Never apply stress to platinum elements, they are fragile and will break easily at high temperatures.

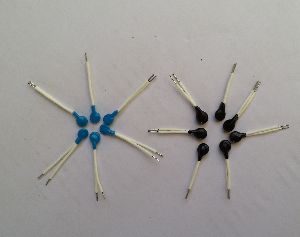

Epoxy Coated NTC Disc Thermistor Temperature Sensor

Get Price Quote

5000 Piece(s) (MOQ)

Introduction - : > We are offering epoxy coated disc thermistor. Description - : > Epoxy coated NTC Disc Thermistor with PTFE insulated nickel lead wires. Dimensions - : 1) Coated Diameter: 3.5 mm � 6.5mm 2) Resistance range : 300 ohm � 68 K Ohm 3) Beta Value : 2950 k � 4300 k 4) Lead: PTFE insulated nickel wire available with customized colors and strand dimensions as per requirement 5) Lead length: As per requirement. Options available Upon Request � Alternative resistance ratings � Rated temperatures and tolerances � Non standard lead length. � Custom specifications. Additional Info - : � Commercials will be fixed only after confirming the product.

Best Deals from Sensors

Slot Sensor

Get Price Quote

1 Piece (MOQ)

"Slot Sensor and part verification array" Rugged Nickel Plated Metal Fixed-Distance Slot Sensor Slot Width: 10 mm to 100 mm; Input 10-30 V dc Output: PNP Pico 3-pin Integral Quick-Disconnect"

Dissolved Oxygen Sensor

Get Price Quote

10 Piece (MOQ)

Microwave Moisture Measurement Sensor Hydro Probe

Get Price Quote

3mm RTD PT-100 Sensors

Get Price Quote

10 Piece (MOQ)

Simplex / Duplex

Honeywell Current Sensor

500 Per Piece

Advantages: Decades of engineering expertise Thru-hole design Fast response times Output voltage isolation from input Minimum energy dissipation Enhanced reliability with adjustable performance and built-in temperature compensation

Occupancy Sensor

Get Price Quote

Occupancy Sensor The Model OSC-200 Omnidirectional Occupancy Sensor automatically controls a HVAC ventilation system. A spherical Fresnel lens provides a 360° detection zone with the use of infrared technology. The integrated dual delay processor saves energy by eliminating false activation due to short-term occupancies. The Model OSC-200 is designed to be ceiling mounted, and is pre-wired for ease of installation. Features: Delay processor suppresses switch activation during momentary occupancy Applications: Lighting control Building energy conservation Install Base Unit: Determine the location of the sensor according to the detection pattern shown in Figure 1a. Remove the cover screw to open the sensor housing as shown in Figure 1b. Remove the circuit board by bending the tab outward (Figure 1b.) Screw the base of the sensor housing to the ceiling through the knockout holes Wiring: Model OSC-200 is pre-wired for ease of use with 22AWG colored wires. Connect the wires as showin in figure 2 Walk Test: Before beginning test, make certain that the On and Off Delay jumpers (located on the circuit board) are connected in the “A” positions as shown in Figure 3. If they are not, follow the procedure under the section titled On/Off Delay Settings to rearrange the jumpers to location “A.” Replace the sensor housing and tighten screw. Storage And Cleaning: The sensor lens is the most delicate part of the Occupancy Sensor. The lens should be kept clean at all times, care should be taken when cleaning the lens using only a soft cloth or cotton swab with water or medical alcohol. Allow the lens to fully dry before using the sensor. The sensor should be installed or stored in an area of room temperature between -4 and 140ºF (-20 to 60ºC). Maintenance: After final installation of the unit, no routine maintenance is required. The Model OSC-200 is not field serviceable and should be returned if repair is needed (field repair should not be attempted and may void warranty). Be sure to include a brief description of the problem plus any relevant application notes. Contact customer service to receive a return goods authorization number before shipping.

Thermocouple Temperature Sensor

Get Price Quote

5 Piece (MOQ)

Hand Held Thermocouple

680 Per Piece

10 Piece (MOQ)

Photoelectric Sensors

Get Price Quote

We are specialized in the supplying of Photoelectric Sensors. Our Photoelectric Sensors are made from technologically advanced machinery and equipment. They promise high quality and durability and therefore our clients have always appreciated the Photoelectric Sensors. We provide the Photoelectric Sensors at the market leading prices for our clients.

Smoke Sensor

Get Price Quote

10 Piece (MOQ)

E2B-M12KS04-WP-B1 Omron Proximity Sensor

350 - 500 Per Piece

10 Piece (MOQ)

Temperature Sensor

700 Per piece

We are offering Temperature Sensor. - Element - J,K,S,R,B,T,E,G,C,D. Pt 100, Simplex & Duplex - Head - Die-Cast Aluminum, Weather Proof I Explosion Proof (Certified by CMRS, Dhanbad) as per application. - Sheath - The material of the sheath is selected as per the media of application and temperature range.

Leuze Make Sensors

Get Price Quote

1 Piece (MOQ)

OMRON TL-W5MD1 Proximity Sensor

1,050 - 1,500 Per Numbers

1 Piece (MOQ)

Proximity Sensor Squire Type BLACK

1000 Watts Schneider Motion Sensor

2,250 - 2,550 Per piece

1 Piece (MOQ)

Handheld Soil Monitoring System

Get Price Quote

1 Piece (MOQ)

Capacitive Sensors

Get Price Quote

We make available various kinds of Capacitive Sensors that have numerous applications in engineering and electronic fields. We offer finest Capacitive Sensors that are made by employing latest technology and high grade raw materials. Our Capacitive Sensors are highly acclaimed by clients all over the India for their toughness, long working life and high performance. Our Capacitive Sensors Are Known For Wide sensing range Robust housing Reliable Powerful performance

DAIP Melt Pressure Transducer

Get Price Quote

The DAIP Series incorporates a heated sensor tip, which limits the potential for sensor damage relating to the membrane, resulting from installation or removal of the pressure transmitter. Additionally it offers the comfort of the DAI series in combination with temperature measurement, allowing for heater control. The Gneuss patented heated sensor tip allows the sensor to be easily removed from a undquot;frozenundquot; melt without any problems. The diaphragm is not damaged when the polymer contracts. The DAIP has revolutionized the handling of critical medias, for example PC, PMMA or ABS. Heater with 24V Patented technology Maximum reliabilty through new membrane technology G-coating to counteract adhesive materials Robust design with G-Armor flexible components Applications with process medias of up 400°C (750°F) possible Pressure ranges from 0-50 and 0-2.000 bar (0-725 and 29,000 psi) Interference resistand signals over long distances 3- and 4-wire technology available With integrated amplifier 0-20 mA, 4-20 mA, or 0-10 V output

Balluff Position Transducer Sensor

1,200 - 3,500 Per Piece

1 Piece (MOQ)

Aquasol AMEORIG Orp Industrial Electrode

3,966 Per Piece

1 Piece (MOQ)

Water Pressure Sensor

Get Price Quote

The company is engaged in the manufacturing and supplying of Water Pressure Sensor all across the country. The Water Pressure Sensor, provided by us, is known for excellent quality and long lasting feature. Designed by using high-grade materials, the Water Pressure Sensor is provided by us at the market leading prices.

Riko Tubular Photo Sensor

Get Price Quote

10 Piece (MOQ)

PT100 R000 Temperature Sensor

999 Per Piece

10 Piece (MOQ)

Master Temperature Sensor

2,500 Per Piece

1 Piece (MOQ)

Temperature Scanner

15,500 - 18,750 Per Piece

10 Piece (MOQ)

Linear Position Sensor

5,000 Per Piece

10 Piece (MOQ)

Ultrasonic Parking Sensor

6,500 Per Piece

1 Piece(s) (MOQ)

BMW Car Brake Pads Sensor

2,250 - 4,500 Per Piece

1 Piece (MOQ)

BMW Car Brake Pads Sensor, Brack Disk Pads, Disk Brack Pads BMW Car, Car Brack Pads, Disk Brack pads BMW 520D,Replacing the rear brake pads on a BMW 7 Series is a relatively straightforward process if you're familiar with basic car maintenance. Here are the general steps you can follow: Tools and Materials Needed: Jack and jack stands Lug wrench Socket and ratchet set C-clamp or brake piston tool New brake pads Brake cleaner Anti-seize lubricant Torque wrench Steps to Replace Rear Brake Pads: Preparation: Park the car on a level surface and engage the parking brake. Loosen the lug nuts on the rear wheels but do not remove them yet. Lift the rear of the car using a jack and secure it with jack stands. Remove the rear wheels. Remove the Brake Caliper: Locate the brake caliper bolts on the rear brake assembly. Use a socket and ratchet to remove the caliper bolts. Carefully slide the caliper off the brake rotor and suspend it using a piece of wire or a bungee cord. Do not let it hang by the brake line. Remove the Old Brake Pads: Remove the old brake pads from the caliper bracket. If the brake pads are held in place with clips, carefully remove these as well. Prepare the Caliper: Use a C-clamp or a brake piston tool to compress the caliper piston. This will create enough space for the new, thicker brake pads. Clean the caliper and surrounding area with brake cleaner. Install the New Brake Pads: Apply a thin layer of anti-seize lubricant to the back of the new brake pads to prevent squealing. Place the new brake pads into the caliper bracket. Reinstall any clips or hardware that were removed. Reinstall the Brake Caliper: Carefully slide the caliper back over the new brake pads and onto the rotor. Reinstall the caliper bolts and tighten them to the manufacturer's specifications using a torque wrench. Reinstall the Wheels: Place the wheels back onto the car and hand-tighten the lug nuts. Lower the car back to the ground using the jack. Use a torque wrench to tighten the lug nuts to the manufacturer's specifications. Final Checks: Pump the brake pedal several times to ensure the brake pads are properly seated. Check the brake fluid level and add more if necessary. Test drive the car at low speeds to ensure the brakes are working correctly. If you're not comfortable performing this task yourself, it's always a good idea to seek help from a professional mechanic.Car Brack Parts supplier.