Sequential Batch Reactor

Get Price Quote

1 Piece (MOQ)

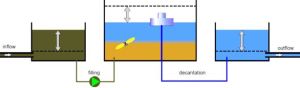

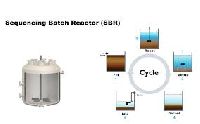

SBR type STP works on the principle of batch treatment of the sewage. Sewage is collected & fed to the reactor in 4 or 5 batches. Air is supplied & the completed aerobic process takes 2 hrs per batch. Once aeration is finished, the sewage comes to a stand-still position so that all suspended solids settle at the bottom thus clarifying the water. Clarified water is then decanted out to be collected In the clarified water tank. This water is further disim fected, filtered & stored or drained. SBR has following features : » Automatic operation of the reactor controlled by a PLC. » Single Tank Operation. » No media addition / replacement. » Intermittent operation so less maintenance. » Low sludge yield, typically once in 10-12 days. » Possible In open, underground & basements. » Water can be reused for gardening & flushing

sequential batch reactor plant

149,998 Per Unit

1 Unit (MOQ)

Best Deals from Sequential Batch Reactor

Sequential Batch Reactor

Get Price Quote

1 Piece (MOQ)

Semi Batch Reactor

Get Price Quote

1 Piece (MOQ)

Sequential Batch Reactor

Get Price Quote

1 Piece (MOQ)

SBR technology operates through a sequential cycle of fill, react, settle, and decant. This flexible process allows for biological treatment and settling to occur in the same reactor, optimizing sewage treatment. Advantages: Energy efficiency, space optimization, and superior nutrient removal.

Sequential Batch Reactor

1,500,000 Per Piece

With our years of expertise and specialization, we are offering a wide range of Sequential Batch Reactors. SBR is an activated sludge wastewater treatment system which is used for removing dissolved and suspended organic material and nutrients. In SBR all the unit operations such as aeration, settling and decanting are achieved in a single reactor, all by automatic operations. Due to this new technology industrial wastewater can now be treated biologically in ideal conditions, regardless of flow or load variations. Phosphorous and nitrates can be removed biologically as well. Benefits: Achieves nitrification, denitrification and phosphorous removal (without chemical addition) in a single reactor Less excess sludge-therefore sludge handling is simpler Hydraulic flexibility-can easily take shock loads Micro organism selection minimizes sludge bulking and controls filamentous bacteria Power savings due to lower oxygen requirements Provides the ability to change any unit process at any time-to achieve a required effect High specific rate of separation in sludge blanket cum clarifier unit Simultaneous nitrification without extra cost No odor problems Reduced operation and maintenance costs No clarifier-further reduction in space and capital cost No sludge recycling-further reduction in 0 and M cost Fully atomized-further reduction in operating cost Application: Small communities and housing colonies Townships Hotels and resorts Schools and universities Defense and military camps Industrial and manufacturing area Municipalities SBR Operation Philosophy: Sequencing Batch Reactor actually represents a very elementary form of treatment process known as "Fill and Draw". Wastewater added to a reactor is treated to remove undesirable component, and is subsequently discharged. The SBR reactor is a self-contained system incorporating equalization, aeration and clarification, within the c

Sequencing Batch Reactors

Get Price Quote

1 Cubic Meter (MOQ)

We are offering sequencing batch reactors, sequence batch reactor sewage treatment plant for individual bungalow,hotels, resorts, commercial complex, industries etc easily accessible for operators and service technicians reliable durable no electrical components.

sequencing batch reactor

Get Price Quote

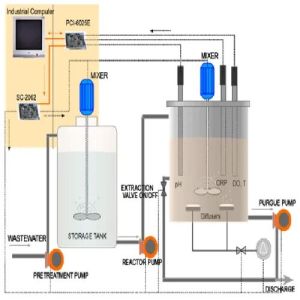

The Sequencing Batch Reactor (SBR) is a derivative of activated sludge process designed to operate under non-steady state conditions. Like extended aeration or other activated sludge process it involves the biological process, microorganisms and mechanical aeration system for aeration along with air distributors and diffusers. However the major difference in involved is in operation of treatment which is carried out in batches in cyclic manner. In SBR configuration all related processes of Aeration, Settling, Decanting are carried out in same basin and eventually this reduces construction cost which is very essential in larger systems. The most important component of SBR process is decanting system. The various type of decanters are used for process like Floating gravity type, rake arm type, floating funnel type and slotted pipe type decanters. The process is operated in batch manner and hence it is vary suitable for industrial wastewater and high flow domestic wastewater. The added advantages are it provides BNR ( biological nutrients removal) and completely digested sludge which makes sludge treatment process easier. SBR is modern wastewater treatment system which involves use of automation in operation. The control of cyclic batch operation is programmed in PLC or SCADA. The instruments involved in process helps to transmit appropriate signal and control the system. The automation of system reduces the number of operator skill and attention requirement and hence improves output quality of treated effluent. Sparkle offers unique design of sequential batch reactor decanting system which involves simple automation and gravity based decanting system. The power requirement for decanting operation is eliminated in this design. Advantages: economical construction due to single tank design. The system can absorb higher shock loads. Provides 95-98% removal in BOD.

Sequential Batch Reactor

Get Price Quote

Sequencing batch reactors (SBR) or sequential batch reactors are industrial processing tanks for the treatment of wastewater. SBR reactors treat biosolids, sewage, sludge or other output from aerobic or anaerobic digesters in "batches." The Sequence Batch Reactor (SBR) cleans the wastewater in one or more batch reactors according to a predetermined sequence of operations. The system performs equalization, aeration and clarification in a single batch reactor. Usually the Pipelife SBR system consists of at least two tanks. In this kind of configuration the first tank – the settlement tank – is used to retain the non-solvent particles. Because of their physical characteristics the non-solvent particles are discarded at the bottom of the settlement tank. The rest of the wastewater is conveyed to the second reactor by the pump on the reactor unit – the Swimmer Unit into the second tank – the SBR.

Sequential Batch Reactor

Get Price Quote

Sequential batch reactor drawing air through the shaft and dispersing it into the water in a horizontal direction. As the propeller rotates, it induces a flow of atmospheric air through the air intake ports on the shaft located above the water surface.

Sequential Batch Reactor

Get Price Quote

estimated that a person disposes 135- 150 litres of water per day. Each person discharges 60 grams of waste into the water when involved in activities such as flushing the toilet, urination, defecation, hand washing, cooking, washing clothes, etc. There is also water being used in kitchen for washing utensils and food preparation. EcoTec sewage treatment systems, ESBR and EcoSBR treat household sewage wastewater. When treated, water can be sent to nature without harmful effects on environment and people. SBR process is reliable and is acknowledged by the Indian regulators and the Pollution control boards. SBR is considered as one of the few promising treatment systems for nutrient removal from sewage water.

Sequencing Batch Reactors

Get Price Quote

Automated Chemical Free SBR Waste Water Treatment Plants We also provide a advanced Pre-Fabricated Chemical Free Automated SBR Waste Water Treatment plant for domestic and municipal application. This Treatment system works on four phases Charging Phase, Treatment Phase, and Settling Phase & Removal Phase. Pretreatment Whether equipped with coarse separator or screen the coarse material is first removed. Buffer The pretreated wastewater next reaches the buffer. Here, loading peaks of a hydraulic or organic types are given intermediate storage during the activated sludge and settling stage and dosed evenly to the current cycle has ended does the filling of the current cycle has ended does the filling of the SBR stage begin. Sequence Batch Reactor Here the biological treatment takes place. In firmly defined cycle mixing (denitrification), aeration (carbon removal and nitrification) and settling take place after charging. With several lines these are filled one after the other. Following complete treatment the removal of the clarified water take place. At the end of the cycle the excess sludge is drawn off the storage tank is again ready for the acceptance of the wastewater produced in the buffer tank. Sludge Storage The surplus sludge can be stored until removal regardless of whether it is in the coarse separator or in a separate sludge store. A cycle can be run according to fixed times or as required. The Ionics works in normal operation at 3 cycles per day. Features Chemical Free No Civil Work Zero Maintenance Low Power Automated Squash Design Odor Free Quick Installation Portable Reduced Noise Min Sludge No Sludge Bed Req Phosphorus Elimination Ortho- phosphate get Splitted during biological treatment process - the rest has to be coagulated. Lot of substrates available (sulfates oder chlorides) with negative side effects like salination and acid reactions. We use Natrium- Aluminat� because: Easier to handle (toxicity) no salination. Reaction without sour waste products. Sludge volume is not effected Sludge weight raises, better settlement, reduces COD values.

sequencing batch reactor

450,000 Per Piece

We are offering sequencing batch reactor.

sequencing batch reactor

Get Price Quote

Our unmatched range of products also includes Sequencing Batch Reactors, which are very easily operable due to their user-friendly nature and have been acclaimed worldwide for their high grade qualities, durability and reliable performance. All our products are manufactured as per the industrial standards and we also offer customization for these products in order to meet the client’s specific requirements. Features: Less maintenance High durability Hassle-free operation

Cyclonic Filter

Get Price Quote

Sequential Batch Reactor

Get Price Quote

SBR is new technology for the treatment of domestic and industrial wastewaters. The SBR can treat wide range of domestic and industrial wastewaters, at flow ranging from few thousand liters to millions of liters per day. The SBR process can treat any wastewater that can be treated by activated sludge process including anoxicoxic systems, aerated lagoons, extended aeration processes, trickling filters, rotating biological contactors (RBCS) and oxidation ditches.

Sequential Batch Reactor

Get Price Quote

Making sure to capture all marketplaces of Bengaluru(India), our organization has arisen as an established provider of this range of product. Far-famed for the excellent Sequential Batch Reactor, we are a notable supplier thriving on the customers' trust for a long time now.

Sequential Batch Reactor

Get Price Quote

Sequencing batch reactor or sbr is a new technology for the treatment of domestic and industrial waste water. It is ideal for treatment of wide range of domestic and industrial waste water at flow ranging from few thousand liters to millions of liters per day. The sbr process treats wastewater by activated sludge process.The Sequencing Batch Reactor (SBR) is an activated sludge process designed to operate under non-steady state conditions. An SBR operates in a true batch mode with aeration and sludge settlement both occurring in the same tank. The major differences between SBR and conventional continuous-flow, activated sludge system is that the SBR tank carries out the functions of equalization aeration and sedimentation in a time sequence rather than in the conventional space sequence of continuous-flow systems. In addition, the SBR system can be designed with the ability to treat a wide range of influent volumes whereas the continuous system is based upon a fixed influent flowrate. Thus, there is a degree of flexibility associated with working in a time rather than in a space sequence. ADVANTAGES:1. High Efficiency of the plant2. Applicable even large capacity plant3. High Retention time increases the efficiency of the plant4. Sludge recycling is required5. Bio-sludge can be used as manure for garden6. Good control of the system since it is a batch process

sequencing batch reactor

Get Price Quote

One Piece (MOQ)

We offer Sequencing Batch Reactor. The Sequencing Batch Reactor (SBR) is an activated sludge process designed to operate under non-steady state conditions. An SBR operates in a true batch mode with aeration and sludge settlement both occurring in the same tank. The major differences between SBR and conventional continuous-flow, activated sludge system is that the SBR tank carries out the functions of equalization aeration and sedimentation in a time sequence rather than in the conventional space sequence of continuous-flow systems. In addition, the SBR system can be designed with the ability to treat a wide range of influent volumes whereas the continuous system is based upon a fixed influent flowrate. Thus, there is a degree of flexibility associated with working in a time rather than in a space sequence.

sequencing batch reactor

Get Price Quote

Process : Sequencing batch reactors (SBRs), due to its operational flexibility and excellent process control possibilities, are being extensively used for the treatment of wastewater which nowadays is fast becoming contaminated with newer and more complex pollutants. SBR reactors treat wastewater such as sewage or output from anaerobic digesters or mechanical biological treatment facilities in batches. Oxygen is bubbled through the mixture of wastewater and activated sludge to reduce the organic matter (measured as biochemical oxygen demand (BOD) and chemical oxygen demand (COD)). The treated effluent may be suitable for discharge to surface waters or possibly for use on land. Advantages : Little land required High effluent quality Fully automatised Lower initial capital cost Can handle large fluctuations in flow Deeper tanks, better AOTR Contaminants Removed : Total Suspended solid, Removal of Nutrients, Removal of Industrial Residues