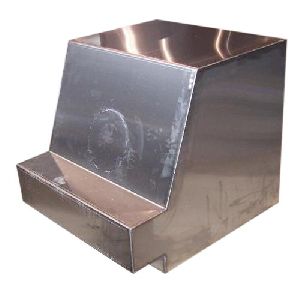

sheet metal fabrication service

150 Per piece

Sheet metal fabrication services involve the process of cutting, bending, and assembling thin metal sheets to create various components and structures. Widely used in industries like automotive, aerospace, construction, and electronics, this service offers versatility and precision. Sheet metal fabrication can produce parts ranging from small brackets to large enclosures. The process uses advanced machinery like laser cutters, press brakes, and welding systems to shape metals such as steel, aluminum, and copper. These services are ideal for both custom and mass production, offering high-quality, durable, and cost-effective solutions tailored to meet specific design and functional requirements.

cnc fabrication engineering service

Get Price Quote

Our CNC Fabrication & Engineering Services deliver precision machining and custom fabrication for diverse applications. Utilizing state-of-the-art CNC technology, we transform your designs into high-quality components, from prototypes to large-scale production runs. Our skilled engineers collaborate with you to ensure optimal functionality and accuracy, while our extensive capabilities cover various materials, including metals and plastics. Committed to excellence and efficiency, we provide tailored solutions that meet your specific requirements, helping you achieve your project goals with confidence and reliability.

Looking for Sheet Metal Fabrication Service Providers

sheet metal work

Get Price Quote

Specializing in sheet metal work, we offer a comprehensive range of services to meet your fabrication needs. From precise cutting and bending to welding and finishing, our skilled team ensures top-quality results. Whether it's custom prototypes or high-volume production, we deliver efficiency and excellence in every project. Count on us for reliable solutions and superior craftsmanship in sheet metal work.

sheet metal services

Get Price Quote

Process Overview – Sheet metal is one of the fundamental forms used in metal working, and it can be cut and formed into a variety of shapes by different methods. Sheet metals are manufactured by cold or hot rolling depending on the type of material and final sheet thickness to be maintained. Generally, if the sheet thickness is below 6mm then it is called sheets and above it is called as plates. They are available for industrial use in the form of flat pieces or coiled strips and shall be selected based on part to be manufactured and its quantum of production. We can process the sheet metal by various methods to meet your requirement such as : Fabrication – Sheet metal is first cut into different profiles by gas cutting, plasma, water jet, wire cut and laser. It is then shaped into a pre-requisite form by bending, rolling, punching etc. to make different parts which are welded together to form a single fabricated structure. We have all the necessary welding qualifications for fabrication such as WPS, PQR and WPQ for manufacturing of boilers, pressure vessels, steel structures etc. Stamping - It includes a variety of operations such as punching, blanking, embossing, bending, flanging, and coining. We can manufacture simple as well as complex shapes at high production rates. It is preferred to go for stamping only when the part design is finalized as the initial investment in tooling is a bit high. However, since the process is almost automated the eventual cost of production per part is very low. Deep Drawing – It is a forming process in which the metal is stretched over a set of dies. In deep drawing the depth of the part being made is more than half its diameter. It is generally done in multiple steps called draw reductions. It can also be done in fewer reductions by heating the workpiece. Normally sheet metals used for drawing is of a particular grade called as D (Drawing), DD (Deep Drawing) and EDD (Extra Deep Draw) since they have better formability properties compared to conventional grade of sheet metal. We can also manufacture deep drawn parts out of different stainless-steel grades. Spinning - Spinning is used to make tubular (axis-symmetric) parts by fixing a piece of sheet stock to a rotating mandrel. Rollers or rigid tools press the sheet metal stock against the form, stretching it until it takes the shape of the form. Capabilities Integrated sequential manufacturing process under one roof i.e Simulation -> Tool designing and manufacturing -> Prototype -> Mass production Simulation software’s used for part development such as Pam Stamp and Hyperform Tool room equipped with VMC measuring up to X axis – 4000mm, Y axis – 2000mm and Z axis – 1000mm Dedicated mechanical and hydraulic presses for prototype part tryouts Prototype to high volume production of up to millions of parts per year based on part configuration Flexibility to choose fabrication, incremental forming, or soft tooling for prototype parts Fabrication of parts weighing more than 10 Tonnes and measuring up to 12 meters in length Stamping and Deep Drawing of parts in stainless steel grade and alloy steels Working with sheet metal thickness in the range of 0.15mm to 8mm Deep draw parts up to 350mm Manufacturing of maximum die size of 4000mm x 1600mm x 1200mm and maximum part size of 2400mm x 1500mm x 500mm Different types of metal finishing services such as fettling, heat treating, plating, anodizing, passivation, phosphating, blackodizing, buffing, galvanizing, metallizing, polymer painting etc. CMM inspection for part validation and approval of stamped and drawn parts Checking fixtures for easy and quick inspection of mass production parts In-house lab tests carried out for raw material verification at production site, certified to NABL standards Complete NDT testing of parts for defect analysis pre and post fabrication as per international standards Availability of WPS, PQR and WPQ qualified by international certifying bodies Customer appointed third party inspection and verification allowed Manufacturing facility certified to IATF 16949 and AS 9100 Rev.D Quality Management System Implementation of Lean Six Sigma tools for better quality control, process control, part traceability and documentation Industry 4.0 integrated manufacturing facilities Application and Benefits The advent and advancement in sheet metal technology has majorly been driven by the automotive industry. The primary target has been to manufacture lightweight - high strength sheet metal parts with good formability and weldability. Most of the parts that go into an automobile include chassis, door panels, roofs, fuel tanks and thousands of other structural parts that are welded or bolted to the main structure. Aerospace, Defence and Marine – Airplane fuselages, wings, plate armor, connectors, fittings, enclosures, housings, couplings etc. Electronics and Lighting – Telecom, computer systems, routers, switches, connectors, servers, custom parts for interior and exterior lighting etc. Sheet metal offers a host of benefits which include : Selection of wide variety of materials Flexibility of manufacturing processes Different tooling options to increase productivity High level of automation and process control High production rates Low per part cost in production

sheet metal fabrication service

25 - 30 Per KG

Elevate your projects with our Sheet Metal Fabrication Service, delivering excellence in precision and versatility. Specializing in custom fabrication, we offer a comprehensive range of solutions tailored to your specific needs. From design to finishing, our skilled craftsmen ensure top-notch quality using cutting-edge technology and techniques. Whether it's prototypes, one-offs, or large-scale production, we handle it all with finesse and efficiency. With a commitment to innovation and customer satisfaction, we guarantee superior results that exceed expectations. Trust us to bring your visions to life with unparalleled craftsmanship and attention to detail. Experience the difference with our sheet metal fabrication expertise

Metal Sheet Fabrication Services

Get Price Quote

Metal Sheet Fabrication Services provide tailored solutions for transforming metal sheets into functional components and structures. Using advanced techniques such as cutting, bending, welding, and assembly, these services ensure precision and high-quality results. Suitable for materials like stainless steel, aluminum, and mild steel, metal sheet fabrication caters to industries such as construction, automotive, aerospace, and manufacturing. The process supports custom designs, complex geometries, and varying thicknesses, meeting diverse project requirements. With state-of-the-art equipment and skilled professionals, Metal Sheet Fabrication Services deliver durable, cost-effective, and reliable solutions for both small-scale and large-scale applications across multiple sectors.

industrial sheet metal fabrication services

Get Price Quote

Shree Krishna Fabrication Work is one of the most reliable and trusted companies for industrial sheet metal fabrication services in India. We are into offering Industrial Fabrication Service to clients all around the country. These are delivered according to the plans and determinations nitty-gritty somewhere near them. Attributable to their dependability, adaptability, specially crafted nature and opportune execution, our administrations are exceptionally requested by the clients. Additionally, our administrations are accessible at market driving cost and are characterized by industry standards and norms. All costs are variable and dependent on future developments according to item particular and prerequisite. Contact us and hire our services without any delay.

Sheet Metal Fabrication

Get Price Quote

We are offering the best Sheet Metal Fabrication Services to the clients. Within our Sheet Metal Fabrication Services, we provide excellent shape and redesign metal of any kind through metal removal or deformation. In our Sheet Metal Fabrication Services, metal sheet is considered as a work piece that is to be processed further into different designs. Here, the thickness of the metal sheet varies and decides the final design of the metal. Within our Sheet Metal Fabrication Services, metal can be bent or stretched ample times to several angles. Here, size of metal parts can vary from small to medium. Material Used Titanium Tin Aluminium Steel Stainless steel Brass Zinc About Sheet Metal Fabrication Process Sheet metal fabrication process includes forming and cutting of metal. During forming process, pressure is applied that causes deformation in the metal sheet.

sheet metal fabrication services

Get Price Quote

Elevate your projects with our comprehensive sheet metal fabrication services. Our skilled craftsmen and cutting-edge equipment ensure precise, high-quality results for all your fabrication needs. From bending and welding to cutting and finishing, we offer a full spectrum of capabilities to bring your designs to life. Whether you need prototypes, custom parts, or large-scale production, we're dedicated to delivering excellence on time and within budget. Partner with us for reliable sheet metal fabrication solutions that meet your exact specifications and exceed your expectations.

sheet metal fabrication services

Get Price Quote

Sheet Metal Fabrication Services offer specialized solutions for creating a wide range of metal products from sheet metal. These services cater to various industries, including aerospace, automotive, electronics, and construction. The fabrication process involves cutting, bending, welding, and assembling sheet metal to produce custom parts and assemblies. Utilizing advanced machinery and techniques, these services ensure high precision, accuracy, and consistency. Sheet metal fabrication is ideal for manufacturing enclosures, brackets, panels, and intricate components. It provides flexibility in design, quick turnaround times, and cost-effective production. These services deliver high-quality, durable, and tailored solutions to meet diverse industry requirements.

sheet metal fabrication services

Get Price Quote

Our Sheet Metal Fabrication Services offer custom-crafted solutions for various industrial and commercial applications, providing high precision and quality in each project. Specializing in the fabrication of parts, enclosures, panels, and structural components, we use advanced techniques like cutting, bending, and welding to deliver exceptional durability and accuracy. With a skilled team and state-of-the-art equipment, we cater to unique specifications, ensuring strength and cost-effectiveness. Our sheet metal services enhance project efficiency and deliver tailored results that meet stringent quality standards.

CNC Sheet Metal Laser Cutting Bending Fabrication Services

Get Price Quote

We Are Providing Sheet Metal Laser Cutting, Bending & Light Weight Fabrication Services Of Stainless Steel, Mild Steel, Aluminium, Copper.

industrial sheet metal fabrication services

Get Price Quote

Our Industrial Sheet Metal Fabrication Services offer comprehensive solutions for custom metal components and structures. We specialize in cutting, bending, welding, and assembling various sheet metals, including stainless steel, aluminum, and mild steel, to meet precise industrial requirements. Our services cater to a wide range of industries, such as automotive, construction, manufacturing, and more. With a focus on quality, precision, and efficiency, we utilize advanced machinery and skilled craftsmanship to deliver durable and cost-effective solutions, ensuring reliable products tailored to your specifications and project needs.

sheet metal fabrications

Get Price Quote

We offer high grade of sheet metal fabrication through our cutting edge technology. Our specialization lies in fabrication of stainless steel and other metals. Our fabricated products are used in various metal working and comprises of the following types.

Sheet Metal Fabrication

Get Price Quote

We undertake all types of sheet metal work from small bracketry to large enclosures, from prototypes and one offs to small and medium batch work. Whatever the job, however small or large, we are committed to quality and precision. We have State of the Art Infrastructure, having Area of land 10750 Sq. Ft. with Unit Power of 75 HP power supply from GEB, includes Machinery, High capacity material handling cranes, Latest software tools and Skilled work force to produce best results in each of these there areas. With these facilities we can manufacture Sheet steel fabricated assemblies from few Kgs. to few Tens of Tons.Following are the steps taken in Sheet Metal Fabrication : Design & Development : We uses Advance software tools are to create 3D model of product as required by the customer & then unfolded with software to get developed drawings of flat product. These drawings are then processing through programs of CNC Laser Machines and CNC Bending Machines. Fabrication Production Line-Up : We have state of the art CNC Laser Cutting machines which can cuts the parts with extremely low tolerance levels. These parts are passed then through the process of shaping i.e. they are then bend using CNC Press Brakes. After Cutting/Bending processes various parts of assembly are sent for fabrication where they are joined by riveting, welding or screwing. This is another critical area for Sheet steel fabricators, as smallest deviation from tolerance limit can cause wastage of entire assembly. The fabricated assemblies are sent for surface preparation and coating. the assemblies are coated by powder coating, Epoxy Painting or Zinc Plating, as per requirement.

Sheet Metal Fabrication

Get Price Quote

Sheet Metal Bending Fabrication

Get Price Quote

Those who are looking for a reputed company that provides Sheet Metal Bending Fabrication services can count on us. We hold expertise in fabricating and bending metal sheets of different sizes and types. For executing our Sheet Metal Bending Fabrication services in effective and time-bound manner, we employ the latest tools and techniques. The service is executed under the strict vigilance of experts. If interested in obtaining our services, you are free to contact us anytime.

sheet metal fabrication service

Get Price Quote

Laxmi Industries is an acclaimed name from Bangalore (Karnataka) that offers the best in class sheet metal fabrication service to the clients all over India. We provide complete fabrication solutions including mild steel sheet metal fabrication, stainless steel sheet metal fabrication, or even any other type of sheet metal fabrication. We are known for providing fabrication services up to clients’ satisfaction. We can customize any item with sheet metal as per the design specifications provided by the clients.

Sheet Metal Fabrication

Get Price Quote

We deals in export quality sheet metal fabricated components of auto parts, e-rickshaw parts, and special kinds components.

Fabrication Shop

Get Price Quote

SINGHASINI welcomes your company to our Metal Fabrication and Assembly Facility. Our Machining, Sheet metal Fabrication and Assembly facility consist of advance equipment, highly motivated and experienced personnel which have been with our company for many years. We have been in business over 40 years. Our 20k sq. ft expandable facility consist of Metal Fabrication Production , Mechanical Test and Quality Control . We are capable of doing Turnkey to your specification and have a full fledged design check service facility. The parts we fabricate are being used in Mineral and Chemical Process Industry. We have an extensive background with handling all type of materials ferrous, nonferrous, exotic metals and casting. We have experience in the fabrication of stainless steel parts and weldments for high pressure and high vacuum systems. Additionally our staff will interface directly with your engineering personnel to improve quality and reduce the cost of the production and proto-type parts.

Sheet Metal Fabrication

Get Price Quote

As a complementary service to our laser cutting and bending solutions, we are happy to be able to provide a complete metal welding and fabrication service. our machine can give strength and finish to mild aluminum, acrylics, brass, mild steel and stainless steel products in small and large batch work. we cover high-speed assembly, CNC punching, drilling, tapping, machining and fitting welding operations.

Sheet Metal Fabrication

Get Price Quote

We provide with pure customized sheet metal fabrication services. We have an advance technology of machinery which provides quality items including Fabricated Sheet Metal Products, cable tray, Sheet metal boxes and many more as per our clients requirement we even provide with different forms and shapes even with wide range. We even maintain quality due to advanced sheet metal fabrication services as with the powerful features forming and bending; we also offer sheet metal components service for electronic, aerospace & defense, architecture, furniture, grill & cement sheet service as per customer needs. We are specialized in providing all type of stainless steel fabrication work. We employ various fabricating procedures viz. cutting, drilling, forming, bending, welding, assembly and finishing manufacturing wide range of sheet metal products. We offer complete stainless steel fabrication work related to: Sheet Metal Enclosures Media Cabinets Electrical Cabinets Industrial Shelving Telecom Racks Covers Cable Trays Fabricated Sheet Metal Products Metal Chassis Sheet Metal Boxes C.N.C Sheet Metal Components Automotive Components

MS Sheet Metal Fabrication Service

Get Price Quote

For fabricating a variety of MS sheet metal structures, feel free to connect with us. At Ganesh Industries, we are committed towards complete client satisfaction. We thus modify our services keeping the functional requirements of the clients in notice. Not just fabrication, we also provide solutions for minor alteration needs of the clients. The company is based in Ahmedabad (Gujarat, India) and we can be reached anytime for a detailed discussion.

customized sheet metal fabrication services

Get Price Quote

Accuracy in fabrication, precision in customization, and quality in work is the promise of Neminox Steel & Engineering Co. when it comes to our customized sheet metal fabrication services. Operating from our base in Mumbai (Maharashtra, India), we are backed by a team of expert engineers who make use of high-end equipment for the fabrication of metal sheets in the desired form. Our experts love challenges and can quickly come up with a quality-assisted solution for the metal sheet fabrication. Contact us anytime to discuss your requirements with our experts.

Sheet Metal Fabrication

Get Price Quote

With the help of our competent team of experts, we are able to provide our customers with high quality Sheet Metal Fabrication service that is widely used in different industries like automobile, electronics, engineering and many other areas. Our offered fabrication service is broadly cherished by our customers owing to its flexibility, reliability and on-time completion. We also provide custom made solutions of these services as per the application requirements of different industries.

Heavy Sheet Metal Fabrication Service

Get Price Quote

We at Barva Conmech are known as a prestigious company in Mumbai, Maharashtra that provides heavy sheet metal fabrication service. Our services are provided by skilled professionals who adhere to the industry's established standards at all times.Furthermore, when providing these services, our professionals make use of the most up-to-date machines and high-quality materials. In addition, a team of professionals thoroughly examines each stage with the goal of maintaining better standards and eliminating any errors that may exist.For development, small-scale production, and manufacturing line interface, we provide laser cutting solutions. This reduces overall costs and improves manufacturing costs and output correctness.

Sheet Metal Fabrication

1 - 1 Per kg

Ours is a Chennai (Tamil Nadu, India) based organization that is engaged in offering trusted sheet metal fabrication services to the clients. We are capable of meeting the exact sheet metal requirements of the clients as we work in close coordination with them. Our proficient engineers conduct the cutting, bending and curving of the sheet metal to form different objects according to the specifications provided by the clients. Moreover, we make use of only high-grade metal and advanced machines for conducting the fabrication process.

Sheet Metal Fabrication

Get Price Quote

sheet metal fabrication service

Get Price Quote

Our Sheet Metal Fabrication Services provide precision-engineered solutions for diverse industrial needs. With cutting-edge technology and skilled craftsmanship, we offer customized fabrication for a range of metal components. From design to production, our services encompass laser cutting, bending, welding, and assembly, ensuring high-quality and accurate metalwork. We cater to various industries, delivering durable and precise metal components and structures. Count on us for reliable, efficient, and tailored sheet metal fabrication services that meet your specific requirements with precision and excellence.

ACP sheet canopy work

250 - 260 Per Square feet

300 Square feet (MOQ)

ACP sheet gliding work And HPL sheet work aal designing Shera board wall cladding work ACP trap folding panel work ACP seat friend elevation work Almuniyam loopers work Aluminium glass partition work Tuffen Glass Work 12 mm 8 mm 6 mm Fall ceiling 2x2 all work Plane Sera board designing all work Puff sheet planning MS structure work Wall concrete sheet MS structure work Wall cement sheet75mm all MS frame work Polycarbonate sheet work multi Wal MS frame Polycarbonate sheet fibre sheet work MS work Polycarbonate roofing sheet work MS frame ACP sign board all latest designing work This is my contact number 7660075600 And second contact number 6202779718 I am materials supplier contract work and with material work insulation service and Labour contract work insulation service