Super Shot Blasting Machine

425,000 Per Piece

1 Piece (MOQ)

sand blasting machine mixing tube

1,820 Per Piece

5 Piece (MOQ)

Best Deals from Shot Blasting Machine

tumblast shot blasting machines

900,000 - 2,000,000 Per ONE

1 Piece (MOQ)

Semi Automatic Shot Blasting Machine

Get Price Quote

tumblast shot blasting machine

Get Price Quote

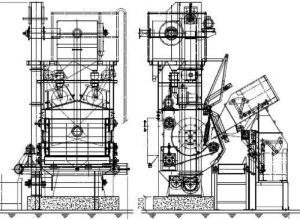

Tumble Blasters process multiple parts, ranging in size from small to medium, with a level of speed and efficiency unmatched by other types of equipment in a comparable price range. Plus they are simple to operate. The operator loads parts onto a rugged perforated belt, closes the loading door, sets the timer and pushes the start button. By tumbling parts within the blast envelope, these machines deliver consistent results automatically whether working intermittently or non-stop in a multi-shift production facility.

Mushroom Valve For Sand Blasting

1 - 5,500 Per Piece

100 Piece (MOQ)

Tumblast Type Shot Blasting Machine

Get Price Quote

Shot Blasting Machine Spare Parts

Get Price Quote

Our company is enlisted amongst the major Shot Blasting Spare Part Suppliers in India. The Shot Blasting Machine Spares offered by us, are available in varied specifications meeting the requirements of the Imported as well as Indian Machines, ensuring optimum spare life compared to imported quality at Indian prices. We provide spares for various brands such as Indabrator (Wheel Abrator) or Nesco, Mecshot, Disa, & Jalandhar made shot blasting machine and imported machines such as Pang Bourn, Chen Hui, Sinto. Types Available Table Type Hanger Type Tumblast Type (Conveyor Belt Type) Salient Features Perfectly removes surface contaminates Precisely cleans metal frames Highly durable Gives uniform surface finish Competitive prices Applications Mechanical cleaning Finishing surfaces

Rotary Type Bin Cleaning Machine

770,000 Per Piece

1 Piece (MOQ)

Cartridge Filter Shot Blasting Machine

Get Price Quote

20 Piece (MOQ)

Shot Blasting Machine

3,800,000 Per Set

1 Set(s) (MOQ)

Quantity of blasting Heads 8 10 10 2 Size of Working Door 1500*2000mm 1200*3000mm 1500*3000mm Head arrangement 2 at the top, 2 on the left , 2 on the right , 2 in the lower Remarks: Symmetrical cross arrangement 2 at the top, 3 on the left , 3 on the right , 2 in the lower Remarks: Symmetrical cross arrangement 2 at the top, 3 on the left, 3 on the right, 2 in the lower Remarks: Symmetrical cross arrangement Body length 6000mm 6500mm 7000mm Cleaning speed 1500-2500mm/min 2000-3000mm/min 3500-5000mm/min Blasting material H beam H beam+H-shaped steel extended legs H beam+H-shaped steel extended legs+H-beamothers parts Surface roughness Ra15-65μm (adjustable) Working hours 16H/Day 20H/Day 24H/Day Adding pellets for the first time 3T 5T 8T 11 Input roller length 10 M 12 M 12 M 12 M Spiral delivery volume 105T / hour 110T / hour 120T / hour Lift capacity 105T / hour 110T / hour 120T / hour Main chamber body High cast iron Guard plate weight 2.5T /set 3.2T /set 4T /set L X W X H 26000x2000x3500mm 30500 x2400x3500mm 31000x2700x3500mm

Shot Blasting Chamber

Get Price Quote

Control cage

Get Price Quote

100 Piece (MOQ)

Rod Bar Shot Blasting Machine

Get Price Quote

1 Piece (MOQ)

Shot Blasting Machine Spare Parts

150 Per Piece

Hanger Type Shot Blasting Machine

1,500,000 - 3,500,000 Per piece

Hanger Type Shot Blasting Machine is precisely designed and developed using high grade raw materials like metals etc. and latest technology at our cutting-edge manufacturing unit. Our Hanger Type Shot Blasting Machine is easy to use and requires low maintenance for a long period of time. It has high tensile strength and resistivity against adverse conditions. We are a prominent Hanger Type Shot Blasting Machine Manufacturer, Exporter and Supplier in Rajasthan (India). Customers can avail our machine from us at affordable prices. Details : The double door hanger type shot blasting machine has two doors located on top of the chamber attached with a hanger on each door. For rotating both hangers, a common rotating friction drive is available After the door gets closed the hanger get engaged to the rotating friction drive automatically which make a hanger to rotate, In this system, the job will be blasted in the chamber with one hanger

Hanger Type Shot Blasting Machine

Get Price Quote

Krishna Engineers are involved in manufacturing and supplying a wide range of Hanger Type Shot Blasting Machine.

Swing Table Shot Blast Machine

Get Price Quote

Swing Table Single Door Our Swing Table Single Door machines are universal type single door machine wherein any variety of components can be loaded on the table either manually or with lifting mechanism. The shot firing being only from top side jobs are required to be turned to expose all sides to the shot flow. The jobs which otherwise can not be hang or tumbled and very heavy are most suitable for this type of machine. This is available in single as well as single door versions and various sizes.

Control cage

Get Price Quote

NON STICK COOKWARE BLASTING MACHINE

Get Price Quote

non stick cookare blasting machine.