Side Seam Welding Machine

Get Price Quote

Wider Application Range Longitudinal Seam Welding Universal Seam Welding Circumferential Seam Welding Side Seam Welding Narrow Track Seam Welding Options Knurled dressing wheel for Electrodes Electrode Drive - Top, Bottom or Differentia

Side Seam Welding Machine

Get Price Quote

Low maintenance cost and long-life are the highlights of the Side Seam Welding Machine, which we offer. These Side Seam Welding Machines are manufactured as per the rules set by the industry. We are among the credible Manufacturers, Suppliers and Exporters of Side Seam Welding Machine.

Best Deals from Side Seam Welding Machine

Side Seam Welding Machine

Get Price Quote

Specially designed damping cylinder with fully pneumatic operation ensures reliability without troublesome oil leakage problems.Antifriction recirculating ball type carriage guide ensures smooth carriage movement and long trouble free operation requiring negligible maintenance.Wire Tensioning system ensures constant wire tension possible on conventional spring loading tension possible on conventional spring loaded tensioning devices.Specially designed overide coupling provided on wire drive pulley allows smooth take up of wire stretch which is not possible on paul and rachet type free wheels.

Side Seam Welding Machine for 15kg Tin,1-4Can, 20-200ltrs Drum

Get Price Quote

1 Piece(s) (MOQ)

The illustrated model is for side seaming to the full-length of the hollow drum and barrel body. Machine body is reinforced fabricated steel structure with a heavy duty transformer used as the main power source, for continuous welding operations.

Side Seam Welding Machine

Get Price Quote

in containers Side Seam welding machine used for side welding of tin can body instead of side lock mechanically. Machine is a trust worthy economically way of producing consistent, faultiness narrow weld at highest working speed eliminating need of skilled operator.

Body Maker

Get Price Quote

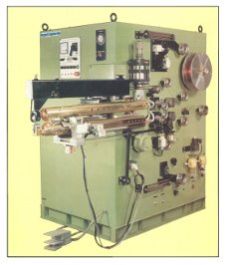

Mechelonic Engineers has now introduced the second generation, fully automatic container side seam welding machine with medium speed production. Machelonic engineers system of container welding is well established for producing continuous, constant narrow weld at optimum working speed, using copper wire as intermediate electrodes. ApplicationsThe machine is designed for medium speed automatic welding of tin sheets in container manufacturing. This machine has flexibility of design to accommodate different sizes of cans from 72 to 450mm length(body height) FeaturesThe machine is fully automatic combining various stages of manufacturing like destacker feeder, flexer, roll forming, overlapping the edges for welding of side seam, transport to welding station, wire drive, welding station, ejection of welding shells and wire collector. ConstructionCompact main frame of welded construction having streamlined appearance. The main transformer, variable speed drives, electronic control system etc. are enclosed in the frame and are easily accessible for serving. Main transformerSpecially designed class ‘F’ insulated transformer, water cooled and fully tropicalised for withstanding continuous operation. Destacker FeederPneumatically operated oscillating arm with a set of vacuum suckers, provided on the machine destacks the blanks and delivers them to flexer rollers. This process is monitored by electronic control system to give command for further operation. A hydraulically operated table is provided for stacking body blanks. This table automatically raises to adjust the level of body blanks for feeding to the flexer. The machine is provided with manetic sheet floaters and air jet separators to facilitate single sheet feed to flexer rollers. FlexerThe body blanks fed to flexing rollers are flexed and moved to roll former. Flexure is provided with rubber coated rollers to avoid damage to printed surface of tin sheet. Roll FormerThe flex banks are automatically moved into the roll former and rolled into desired shapes. Roll former has arrangement to adjust the body rolling diameter within specified range. Centering FlapsThe rolls blacks are collected by a set of pneumatically operated flaps, which also guides edges of rolled body in catch bar. A separate set of flaps are required for each range of body diameter. Crown AssemblyThe crown assembly near welding station controls exact diameter of body before welding. This assembly can be calibrated outside the machine on a setting mandrel. Calibrating Ringfor welding with narrow overlap (0.5mm), calibrating ring assembly provided on the machine will maintain parallel overlap.One set consisting of crown assembly, crown setting mandrel, centering flaps and calibrating ring will be provided with machine for a specific size of can as standard. Other sizes will be available on additional cost. Upper ArmThe upper arm is manufactured from special grade high tensile brass of suitable cross section to minimize any deflection during normal operation. The upper weld wheel and Z- bar are fixed to this arm. Arm is water cooled.Note: tooling for 301 and 302 at extra cost: Tooling for 301 and 307 together with a small arm could be supplied as aspecial case provided the customer uses Tin plates of Temper T3. Catch- Bar and Z-BarThe machine is provided with catch-bar and Z-bar to control overlap and also to guide the shell, while welding. Welding StationWelding station consists of two anti-fiction type weld wheels, made of special copper alloy with mercury contacts. These weld wheels are water cooled. A specially made weld wheel holder for lower weld wheel is provided. Welding pressure is provided by lower weld wheel. A single copper wire running over weld weld wheels act as intermediate electrode. The formed body of can is transported to welding station. The arrival of can is sensed through an electronic system and welding initiates and completes automatically. In this machine welding is at the bottom of can. Wire Flattening UnitA controlled drive with rollers, flatten the copper wire to the required flatness before entering the wire feeding system. Wire Feeding SystemAn accurate variable speed drive with electromagnetic clutch brake system and control wire tensioning devices provide positive and precise fed control of copper wire. Ejection of Welded ShellsWelding shells are received on a magnetic conveyor and ejected on the main conveyor. Wire controlling SystemThe copper wire used as the intermediate electrode for welding is wound on a re-coiler. Control PanelA centralizedcontrol panel is provided with facilities like operating switches, pilot lamps, ammeter, current fine setting, batch counter and continuous counter of cans. Machine is also provided with additional facilities like single cycle mode and setting up mode. Operating cycleLoad body blanks on the table, adjust parameters on the machine, operate the start switch. The machine instantaneously starts and continues to weld the body blanks. The operator has to only ensure that the destacker table has enough stock of body blanks. The automatic function includes picking up of the body blanks, flexing roll forming, guide to the catch- bar and then to Z-bar and welding at the welding station. The welded bodies are automatically ejected out. Safety FeaturesSafety features like No Wire Detector, Wire Cut-off Detector, No Can Detector, No Guard Detector Weld Wheel Position Detector are part of the machine. Side Stripping System The Machine can be provided with Nordson internal and external liquid lacker stripping system, alongwith take of conveyor and suitable cutting system at additional cost.

Side Seam Welding Machine

Get Price Quote

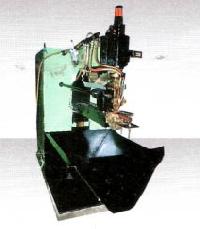

The illustrated model is for side seaming to the full-length of the hollow drum and barrel body. Machine body is reinforced fabricated steel structure with a heavy duty transformer used as the main power source, for continuous welding operations. The machine is equipped with upper and lower weld wheel assembly, water cooling system and built in welding transformer.

Side Seam Welding Machine

Get Price Quote

Tin containers Side Seam welding machine used for side welding of tin can body instead of side lock mechanically. Machine is a trust worthy economically way of producing consistent, faultiness narrow weld at highest working speed eliminating need of skilled operator.

Side Seam Welding Machine

Get Price Quote

MECHELONIC ENGINEERS Container Side Seam Welding Machine model 18-51 is a trustworthy and economic way of producing consistent, faultless and narrow weld at highest working speeds eliminating need of skilled operator.

Side Seam Welding Machine

Get Price Quote

Kirpekar make longitudinal seam welding machine offers to weld the last side of the radiator automatically . The machine is programmed to weld both the ends of the raditors which is sutibale of any length of radiator.

Side Seam Welding Machine

Get Price Quote

Tin Container Welding Machine, Container Sides Seam Welding Machine, Capable of Welding 12000 cans of 1 litre capacity8 hr. shift

Side Seam Welding Machine

Get Price Quote

The illustrated model is for side seam welding to full length of the hollow drum & barrel body. The machine body is steel fabricated with extra ribbings & heavy structural design with heavy duty transformer used as the main power for continuous welding operations. The machine is equipped with upper & lower weld wheel made out of good quality Beryllium copper; its bearing’ shaft, housing etc. are all made of Brass & Copper. D.C variable drives with electronic speed control, water cooling system with necessary valves. Multi tapping system, welding transformer for load selection, best available pneumatic equipment like power cylinder piping & D.C valve etc. the logic control with timer & heat control standard card for getting best possible welding quality. Microprocessor is also available on request with a bypass connector switch is provided.

Drum Side Seam Welding Machine

Get Price Quote

Side Seam Welding Machine

Get Price Quote

We are one of the main side seam welding machine manufacturers, exporters, and suppliers from india. Our side seam welding machine is available with heavy-duty transformer and water cooling system. Our side seam welding machine has found its application in various drum manufacturing industries due to its superior quality and unbeatable performance. attributes : robust structuretensile strength maximum durability anti- corrosive highly reliable used for : full length side seaming of the hollow drum and barrel body

Side Seam Welding Machine

Get Price Quote

Side Seam Welding Machine, Spot Welding Machines

special purpose side seam welding machines

Get Price Quote

special purpose side seam welding machines, can making machines

Side Seam Welding Machine

Get Price Quote

Side Seam Welding Machine, can seamer machine, circular body rolling machine

Side Seam Welding Machine

Get Price Quote

Side Seam Welding Machine, Treadle Shearing Machine

Side Seam Welding Machine

Get Price Quote

Side Seam Welding Machine, Spot Welding Machines, Spot Welding Machines

Side Seam Welding Machine

Get Price Quote

Side Seam Welding Machine, MIG welding machine, Arc Welding Machine