Sigma kneader

Get Price Quote

1 Piece (MOQ)

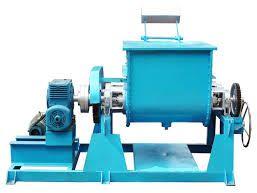

Uses/Applications Widely utilized for manufacturing stiff paints (OBD) and putty Excellent for kneading & mixing of highly viscous materials like dough, putty, rubber solution, adhesives and polymers Used in processing printing inks, pigment paste and construction chemicals Features Widely utilized for manufacturing stiff paints (OBD) and putty Ability to withstand heavy static and dynamic loads Easy installation Corrosion resistant surface finish Hassle-free operations Energy efficiency

Sigma kneader

Get Price Quote

Best Deals from Sigma Kneader

Sigma kneader

Get Price Quote

The Sigma Mixer is used for mixing and kneading for mixing, kneading of highly viscous mass, sticky and dough like products, Mixing of pastes, rubber, and heavy plastic masses, applications in Food, Rubber, Pharmaceutical, Chemical and agro industries, Dry powder to wet phase mixing. This mixer is most suitable for highly viscous material and dough like masses. The sigma kneader is a double arm mixer, the two “Z” blade rotate towards each others at same or different speed inside a W- shaped product container. The twin screw basin kneading machine with two horizontally arranged kneading blades, which are deeply geared into one another and strip themselves reciprocally. Each blade moves the material in opposite direction thereby providing excellent cross mixing of all raw materials. The blades pass the trough walls and each other at close clearances resulting in good mixing. The close clearance produces a shearing and tearing action that is beneficial to the size reduction of solids. Selection of appropriate blade shape and speeds result in excellent mixing

Sigma kneader

Get Price Quote

We offer used sigma Kneader for sale of SS with MS jacket, size of mixer is 2 ft breadth 2 ft height x 2.5 ft length. It is complete with helical gear box, with motor & reduction gear box for tilting the mixer.

Sigma kneader

Get Price Quote

1 Piece (MOQ)

Working Principle & Features RENDER’S offer to our clients superior range of sigma kneader machinery equipment. Our product is suitable for kneading, dispersing and mixing of highly viscous material. It is mostly used in the chemical, pharmaceutical, food, adhesives, dyestuff, paint, refractory, rubber, plastic and related industries. They comprise of a double u shaped container welded and machined together. We have kept the clearance between the blades and the walls of the container to the minimum for ensuring maximum efficiency in the kneading and mixing action.

Sigma kneader

Get Price Quote

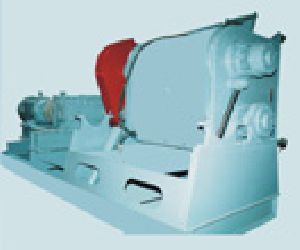

The sigma kneader is a double arm mixer with extruder, the two "Z" blade rotate towards each others at same or different speed inside a W- shaped product container and extruder screw is located between the two blade with separate gear motor drive. The extruder screw is rotates in forward direction for extruding process and rotate in reverse direction during mixing process. Speed of the extruder to be adjustable by VFD. The twin screw basin kneading machine with two horizontally arranged kneading blades, which are deeply geared into one another and strip themselves reciprocally. Each blade moves the material in opposite direction thereby providing excellent cross mixing of all raw materials. The blades pass the trough walls and each other at close clearances resulting in good mixing. The close clearance produces a shearing and tearing action that is beneficial to the size reduction of solids.

Sigma kneader

Get Price Quote

Pioneer Engineering Company offers Sigma Kneader Mixer is the most wide and original column of horizontal Sigma Kneader Mixers manufacturers in India used for mixing powder, dough, cream, batter, paste, sludge, slurries and granule for a variation of applications such as the banking industry, Pharma, ceramics, sealing compounds, metal residue, adhesive, brake lining, confectionery, carbon black, ceramic powders, grease, captivating tape coatings, silicone rubber, soap & detergent. Sigma Kneader Mixers Manufacturers in India by the industry’s leading talent right here at India. We ripen technology of Sigma Kneader Mixers manufacturers in India that not only makes the mixing process more consistent, but moreover decreases downtime during maintenance-free and improved cleanliness designs.

Sigma kneader

Get Price Quote

Excellent for kneading and mixing of highly viscous materials like dough, putty, rubber solutions, adhesives, polymers etc. The mixing action is a combination of smearing, stretching, folding, dividing and recombining as the material is processed between the sigma blades and the container walls. Jacket arrangement is provided for heating or cooling application. In bigger models the container is tilted by a hydraulic cylinder to ensure complete discharge of mass. The Kneader Extruder combines the efficiency of a double arm - sigma blade mixer with the convenience of an extrusion screw for the mixing and discharging of heavy viscous materials. Such as Adhesives, Explosives, Mastics, Sealing compounds, Biscuit dough’s, Fiberglass resin dough’s, Metal powders, Silicone rubber, Butyl rubber, Food and confectionery products, Moulding preparations, Soaps and detergents, Carbon pastes, Gaskets and Gland Packing’s, Pencil erasers, Solid propellants, Ceramics Grinding wheel preparations, Pharmaceuticals, Sugar pastes, Chemicals, Hot-Melts, Plastics, Viscous rubber solutions, Chewing gum, Inks and pigment products, Putties, Crayon and pencil lead, Marzipan, Refractories. The Kneader Extruder includes a set of counter-rotating kneading blades and a discharge screw. The blades are mounted on a horizontal axis in a u-shaped trough. Below the blades in a separate cavity is the discharge screw. During the mixing cycle the blades rotate toward each other while the mixing screw rotates in a reverse direction, constantly feeding new materials into the mixing blades. After the mixingkneading cycle is complete, the screw is reversed and it transports the mixed materials from the mix zone out through a discharge die and on to further processing or packaging.

Sigma Kneader With Extruder

Get Price Quote

Sigma kneader

Get Price Quote

Excellent for kneading and mixing of highly viscous materials like dough, putty, rubber solution, adhesives, polymers etc. The mixing action is a combination of shearing, stretching, folding , deviding, and recombing as the material is processed between the the sigma blades and the container walls. Jacket arrangement is is provided for heating or cooling application.

Sigma Mixer cum Kneader

Get Price Quote

Sigma Mixer (kneader)

Get Price Quote

Sigma Mixer : SIGMA MIXING MACHINE is a heavy-duty mixer specially designed to produce uniform mixing, blending & kneading of highly viscous, paste & dough type materials. Sigma mixer is used for kneading of putty, epoxy, paints, pigments, adhesives, gums, battery pastes, welding electrode flux, catalysts paste, plastic compounds, rubber compounds, papad, chocolate, bubble gum, etc. The tangential action of mixing and kneading is thoroughly obtained by two 'Z' shaped kneading blades, which rotates very accurately at different speed towards each other causing the product to be transferred from one blade to the other. The mixing action is a combination of bulk movement, stretching, folding, dividing, and recombining of the material. The shearing & tearing action of the material against blades and the side walls causes size reduction of the solids. Sigma Mixer Operation Sigma mixer, the tangential action of mixing and kneading is thoroughly obtained by 'Z' (SIGMA) shaped kneading blades, which rotates very accurately at different speed towards each other causing product to be transferred from blade to blade. Discharge of the mixed product is achieved by tilting the container or through the valves at the bottom or by means of an extrusion screw below the container if provided Sigma Mixer Options GMP / Non GMP / models. Discharge in sigma mixers is done by tilting container / bottom sliding valves / bottom gates / flush bottom gate valves. Tilting in sigma mixers is done by hand liver / hand wheel with lead screw / electrical arrangements / hydraulic systems. Lifting of lead either manually, with help of counter weights or hydraulically. 'Z' Type Spiral blade / Naben / double naben blades to circulate hot / cold water in cases of heavy masses. Jacketed shell for heating or cooling by steam, oil, water etc. with fiber glass insulation over the jacket. Spray system for liquid addition / gas purge. Flame proof / Non-flame proof electrical controls. Salient Features Sigma Mixer is a Batch type Mixer In sigma mixer, Mixing Trough and Blades are fabricated from mild steel, stainless steel 304 and 316 grade. Blades of sigma mixers are designed to obtain thorough mixing of high viscosity materials. Sigma Mixers Blades are machined to keep minimum equal gap between through walls and blades. Sigma mixers have fixed with Heavy-duty gears to sustaion of load of Kneading. Shaft sealing into the stuffing boxes is provided by Teflon Chevron Rings / PTFE breaded gland rope to prevent leaking from blade ends. Safety Guards and Grills are provided for maximum safety in sigma mixers.

Sigma kneader

Get Price Quote

MIKRONS sigma kneader is a twin basin kneading machine with two horizontally arranged kneading blades, which are deeply geared into one another and strip themselves reciprocally. The kneading blades run to a ratio 1:2 Because of their different speed, the blade sides approach and withdraw alternately. This causes high pressure tensile and shearing rates and therefore heavy friction in the kneading medium, which creates excellent dispersing and homogeneity. The shape of the kneading blades enables a steady flow of material from the side walls of the kneading trough to the middle of the kneading trough. Design Highlights The two Z arm mixing blades rotate towards each other at differential speed inside a W-shaped trough Each blade moves the material in opposite direction thereby providing excellent cross mixing of all raw materials. The blades pass the trough walls and each other at close clearances resulting in good mixing. The close clearance produces a shearing and tearing action that is beneficial to the size reduction of solids. This mixer is most suitable for highly viscous material and dough like masses. Selection of appropriate blade shape and speeds result in excellent mixing. On completion of the mix cycle, the trough of the mixer is tilted and the product is discharged. The mixer is also available with a bottom opening design for discharge Wide range of blade types to choose from

Sigma kneader

Get Price Quote

This machine comprises of a double 'U' shaped container welded and machined together inside which rotates two 'Z' shaped sigma blades in opposite directions. The clearances between the walls and the container are kept to a minimum to ensure maximum effciency in kneading and mixing. The shafts of the sigma blades are fitted in bearing blocks which are each provided with roller bearings, steel glands/teflon rubber seals for smooth and leakless operations. The kneader is mounted on a sturdy base frame fabricated out of ISMC sections and are free from vibrations. For cooling and heating jackets are provided.These types of machines are available in M.S. And S.S. contruction. The kneader can be tilted by means of a mechanical system or manually and for bigger models beyond 250 Kgs we provided hydraulic tilting.Hydraulic tilting system is provided with complete power pack, electric motor, pressure valves, pipes, fittings, cylinders and hoses which makes the tilting mechanism quick, easy and simple to operate.

sigma kneaders

Get Price Quote

Sigma Kneaders that we are offering are specially designed for achieving desired results in High Sheer wet milling, Pigment flushing or even high viscous mixing. Our MARSHAL’ Sigma Kneaders are manufactured from superior grade components and in compliance with the set industrial norms and standards. The performance deciding features are well studied, giving high performance yet low maintenance. We are a prominent Sigma Kneaders Manufacturer, Exporter and Supplier from Gujarat, India. We make them available in various sizes and specifications. Features Optimum nearest blade to wall distance Maintenance friendly stuffing box design Hydraulic tilting arrangement Easy Lid opening Mechanism High tensile blades for high Sheer force requirements. Stringent Quality Control (X-Ray Test, Stress Test & Inter granular Corrosion Test) Ideal Blade helix angle with superior blade design for High sheer applications Application specific customization Applications Pigment Dispersions Pigment Manufacturing Flushed Pigments Epoxy-putty Rubber solution & adhesives Soap Chewing gum Stationary Colors Ointment Plastic Compound Activated Carbon Sizes Available 5 Litres 200 Litres 450 Litres 1000 Litres 2000 Litres

Sigma kneader

Get Price Quote

Excellent for kneading and mixing of highly viscous materials like dough, putty, rubber solutions, adhesives, polymers etc. The mixing action is a combination of smearing, stretching, folding, dividing and recombining as the material is processed between the sigma blades and the container walls. Jacket arrangement is provided for heating or cooling application. In bigger models the container is tilted by a hydraulic cylinder to ensure complete discharge of mass.

Sigma kneader

Get Price Quote

The Sigma Mixer is used for mixing and kneading for mixing, kneading of highly viscous mass, sticky and dough like products, Mixing of pastes, rubber, and heavy plastic masses, applications in Food, Rubber, Pharmaceutical, Chemical and agro industries, Dry powder to wet phase mixing. This mixer is most suitable for highly viscous material and dough like masses. The sigma kneader is a double arm mixer, the two “Z” blade rotate towards each others at same or different speed inside a W- shaped product container. The twin screw basin kneading machine with two horizontally arranged kneading blades, which are deeply geared into one another and strip themselves reciprocally. Each blade moves the material in opposite direction thereby providing excellent cross mixing of all raw materials. The blades pass the trough walls and each other at close clearances resulting in good mixing. The close clearance produces a shearing and tearing action that is beneficial to the size reduction of solids. Selection of appropriate blade shape and speeds result in excellent mixing

Sigma Mixer Kneader

240,000 Per Units

Sigma kneader

Get Price Quote

This machine comprises of a double 'U' shaped container welded and machined together inside which rotates two 'Z' shaped sigma blades in opposite directions. The clearances between the walls and the container are kept to a minimum to ensure maximum effciency in kneading and mixing. The shafts of the sigma blades are fitted in bearing blocks which are each provided with roller bearings, steel glands/teflon rubber seals for smooth and leakless operations. The kneader is mounted on a sturdy base frame fabricated out of ISMC sections and are free from vibrations. For cooling and heating jackets are provided. These types of machines are available in M.S. And S.S.contruction. The kneader can be tilted by means of a mechanical system or manually and for bigger models beyond 250 Kgs we provided hydraulic tilting.Hydraulic tilting system is provided with complete power pack, electric motor, pressure valves, pipes, fittings, cylinders and hoses which makes the tilting mechanism quick, easy and simple to operate. Range of Products * Triple Roll Mills * Ribbon Blenders * Hydraulic Dissolvers * Pug Mixers * High Speed Mixers * Planetary Mixers * Batch type Sigma Mixer Machines * Conical Blenders * Continuous Sigma Mixer Machine * Resin Plants * Bead Mills * Turnkey Projects Applications * Varnishes & Paints * Resins, Glues, Adhesives * Polyurethanes * Pharmaceuticals * Inks * Chemicals * Foods * Lacquers * Colourants * Cosmetics

Sigma kneader

Get Price Quote

MIKRONS sigma kneader is a twin basin kneading machine with two horizontally arranged kneading blades, which are deeply geared into one another and strip themselves reciprocally. The kneading blades run to a ratio 1:2 Because of their different speed, the blade sides approach and withdraw alternately. This causes high pressure tensile and shearing rates and therefore heavy friction in the kneading medium, which creates excellent dispersing and homogeneity. The shape of the kneading blades enables a steady flow of material from the side walls of the kneading trough to the middle of the kneading trough.