Green Silicon Carbide

80 - 90 Per Kilogram

1 Metric Ton (MOQ)

Silicon Carbide

Get Price Quote

Best Deals from Silicone Carbide

Silicon Carbide Foam

1 - 2 Per Pack

1 piece (MOQ)

Green Silicon Carbide

80 Per Kg

100 Kilogram (MOQ)

Green Silicon Carbide

Get Price Quote

Our rich industrial experience enables us to come up with the best Green Silicon Carbide. It is manufactured in adherence with the defined parameters of the industry. Green Silicon Carbide is used for processing hard alloy and metallic & non-metallic material. Highlights : Resist high temperature and pressure Resistance against corrosion & thermal shock High strength Durable

Foundry Grade Silicon Carbide

65 Per Kilogram

100 Kilogram (MOQ)

Foundry Grade Silicon Carbide -Used for addition in SG and Cast Iron foundries for the Recovery of Silicon and Carbon . This is cost effective replacement of Ferro Silicon . We offer excellent qulaity product with 88-90 % Silicon Carbide which yields recovery of Silcon to 58- 60 % and Carbon recovery of 23-27 %. The product is now widely accepted as cost competitive replacement of Fero Silicon.

Silicon Carbide

Get Price Quote

Silicon Carbide

Get Price Quote

Silicon Carbide

Get Price Quote

We are supported by a team of professionals who ensure that the offered lot is prepared using the best quality raw material. Also, they confirm that the material is sourced from the certified places. Customers' satisfaction is our utmost priority and thus, we deliver only certified array of products to them.

Black Silicon Carbide

Get Price Quote

Manufacturers & suppliers of black silicon carbide, green silicon carbide, aluminium oxide (brown, white & pink) etc. Available second grade quality for the same.

Black Silicon Carbide

Get Price Quote

We are instrumental in bringing to you supreme quality of Black Silicon Carbide, which is formulated in electric resistance type furnace at high temperature. Our Black Silicon Carbide is manufactured with good quality raw materials such as quartz sand and petroleum coke. The Black Silicon Carbide is offered to clients at economical rates. Available in varied mesh sizes F12, F14, F16, F18, F20, F24, F30, F36, F46, F54, F60, F80, F100, F120, F150, F180, F220, F250, F320, F-320 etc. Used As Refractory materialMetallurgical additive and so on

Silicon Carbide 90

Get Price Quote

Black Silicon Carbide

85 Per Kilogram

500 Kilogram (MOQ)

Rainbow Carborundum Silicon Carbide

Get Price Quote

Silicon Carbide

Get Price Quote

Backed by an extensive supply network, our organization is grouped among preeminent Suppliers of Silicon Carbide. As a trusted name, we conduct different quality tests at all stages to make sure that our offered range is defect free.

Silicon Carbide

Get Price Quote

Black Silicon Carbide

170 - 300 Per kgs

Black Silicon Carbide grains for bonded applications. Used in the manufacture of grinding wheels, polishing blocks, rubbing bricks, honing sticks, foundry fluxes, rice and dal-mill, shellers, for abrasive blasting, lapping, cutting and polishing of gems and granite, antiskid surfacing and other general purpose applications.

Green Silicon Carbide

250 Per Kilogram

2 Kilogram (MOQ)

Green Silicon Carbide Powder is Green colour Abrasive Powder from grit:16 to 220 & mesh:400 600,800,1000,1200& 1500 .Average price 250 to Rs.270/- per Kg +GST@18%. Prices are nett ex our godown delivery. Packing is 25 Kgs. Bag. Contact :Universal Trading Corporation. Goregaon ( West ). Mumbai -400104 Mob://

Black Silicon Carbide

Get Price Quote

Silicone Carbide

1,800,000 - 2,000,000 Per ton

Carbide drill, insert, bush and dies

Black Silicon Carbide

Get Price Quote

It's rs 170 per kg plus tax upgrade me mesh size delivery from Delhi 15 days after recived payment Gautam tayal Gautam brothers gautamtayal@yahoo.co.in

Silicon Carbide

560 - 1,034 Per 公斤

5 ton (MOQ)

Silicon Carbide

70 Per Kilogram

100 Kilogram (MOQ)

Saint Gobain Silicon Carbide Rollers

30,000 - 80,000 Per Unit

25 Units (MOQ)

silicon carbide rollers, silicon carbide rollers for furnace next generation for roller hearth kilns lithium-ion batteries are ubiquitous in electric vehicles and storage, handheld electronics, medical equipment, power tools, and many other products. suppliers must respond to this increasing demand by developing new battery chemistries for greater energy density while boosting recycling efforts and expanding battery production. roller hearth kilns (rhk’s) operating at high temperatures and caustic environments (atmosphere, volatilizing compounds, etc.) are critical to manufacturing the cathode powders required in lithium-ion batteries. saint-gobain has developed a exclusive quality control technique for measuring roller strength. end user benefits include: reduced delivery of sub-standard parts consistently high (and improving) roller strength/capacity reduced frequency of breakages which can lead to kiln idling using a blue light laser measurement system, tir is measured and controlled across the length for all rollers. this leads to: • necessary spc data for process optimization and control • precise measurement data available for each roller shipped • low product variation upon delivery best-in-class silit® rollers offer distinct mechanical, thermal, and corrosion-resistant characteristics, delivering unparalleled performance. this trusted, reliable material technology helps reduce energy consumption and increase productivity for dpf/gpf filters, substrate manufacturing, and roller hearth furnaces used for the thermal treatment of lithium-ion powder mixes. our materials withstand • thermal shock & temperature gradients• corrosion due to lithium source (lioh, li2co3) • automated handling & vibration markets served delhi, mumbai, kolkata, chennai, bangalore, pune , ahmedabad, vadodra,surat, vapi, aurangabad, kohlapur, raigad, raipur, lucknow, jaipur, udaipur, trivandrum, coimbatore, bhopal, gurgaon, raipur, manesar, bhubaneshwar, jamshedpur, hyderabad, vizag, vijayawada, goa, hosur, nagpur, rajkot, kanpur, india silicon carbide rollers, carbide rollers, silicon carbide rollers for furnace

Silicon Carbide

Get Price Quote

1 Ton (MOQ)

max phase Titanium silicon carbide

Get Price Quote

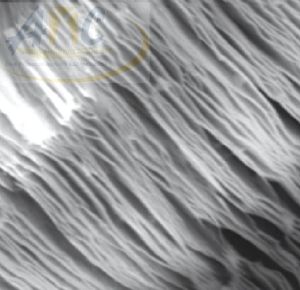

Titanium silicon carbide Ti3SiC2 is a member of vdW MAX layered material system. Similar to graphite and MoS2, the MAX phases are layered and have the general formula: Mn+1AXn, (MAX) where n = 1 to 3, M is an early transition metal, A is a non-metal element and X is either carbon and/or nitrogen. In this particular case, M=Ti, A=Si, and X=C with n=3. Worlds first electronic and optical grade commercial layered MAXene phase Ti3SiC2 materials: Ti3SiC2 MAX phase has been synthesized at our facilities using large reactor chemical vapor deposition to yield Worlds highest purity (99.999% or higher guaranteed) and layered MAX phases. The MAX phases are electrically and thermally conductive due to their metallic-like nature of bonding. They are excellent for research quality materials as 2D metals, battery applications, supermetallicity, thermal physics, or as precursors for MXene production. They have been also subject to research for isolating single layer Silicon (silicene) or Al (alumine) owing to isolated Si and Al between layers (see atomistic views). Ti3SiC2 product consists of microsized layered crystals that measure from 1 micron to 100 microns in size (see SEM images below). Each order contains 100 grams of high purity and layered Ti3SiC2 MAXenes sealed under inert Ar gas. The product has been perfected in the last years to reach guaranteed 3:1:2 Ti:Si:C ratios and exhibit extraordinary environmental stability. XRD peaks are rather sharp and SEM images clearly exhibit layered nature of the flakes. Each crystallite can be exfoliated either using conventional tape exfoliation or alternatively liquid phase exfoliation technique. If you have a specific type of new MAXene and MXene phases in mind please contact us. Our research and development team will be happy to design, synthesize, and provide with new types of materials on demand.

Fickert Brush Silicon Carbide

Get Price Quote

Fickert antique brush Silicon carbide grit type Nylon 612 30mm Length filament Used on radial arm machines or any machines To make amazing antique grinding on Granite On wet condition

Silicon Carbide Black

Get Price Quote

Black Silicon Carbide is produced in electrical internal resistance furnaces from high purity silica sand and petroleum coke. Its combination of being very hard and sharp makes it a very aggressive abrasive ideal for many applications. Black SiC is typically used on hard or brittle materials. It is also used for kiln furniture, lapping and polishing, non-woven, tumbling, pressure blasting, anti-skid, electrical heating elements, aerospace, composites, etc.

Black Silicon Carbide

100 Per Kilogram

100 Kilogram (MOQ)

Black Silicon Carbide

198 Per Kilogram