NST 1600C High Temperature Microwave Sintering Furnace

250,000 - 1,650,000 Per piece

1 Piece (MOQ)

Sintering Furnaces

Get Price Quote

We manufacturing sintering furnaces for heat treatment of sintered powder with metal at hi- temperature with latest technology international affiliated energy efficient design, low running cost, accurate controlling with automatic thyristor control panel, high density insulation with in- heart atmosphere to avoid oxidation. we have continuous mole sintering furnaces and batch type sintering furnaces as per requirement.

Best Deals from Sintering Furnaces

PIM & MIM Vacuum 2nd Stage Debinding and Sintering Furnace

Get Price Quote

Metal Injection Molding (MIM) ProcessMetal injection molding (MIM) offers a manufacturing capability for producing complex shapes in large quantities. The process utilizes fine metal powders (typically less than 20 micrometers) which are custom formulated with a binder (various thermoplastics, waxes, and other materials) into a feedstock which is granulated and then fed into a cavity (or multiple cavities) of a conventional injection molding machine. After the “green” component is removed, most of the binder is extracted by thermal or solvent processing and the rest is removed as the component is sintered (solid-state diffused) in a controlled-atmosphere furnace. The MIM process is very similar to plastic injection molding and high-pressure die casting, and it can produce much the same shapes and configuration features. However, it is limited to relatively small, highly complex parts that otherwise would require extensive finish machining or assembly operations if made fromany other metal-forming process.The advantages of the metal injection molding process lie on its capability to produce mechanical properties, nearly equivalent to wrought materials, while being a net-shape process technology with good dimensional tolerance control. Metal injection molded parts offer a nearly unlimited shape and geometric-feature capability, with high production rates possible through the use of multi-cavity tooling.Process Overview FeedstockMixing and Granulating - The first step in the MIM manufacturing process is the production of the feedstock that will be used. It begins with an extensive characterization of very fine elemental or pre-alloyed metal powders (generally less than 20 μm). In order to achieve the flow characteristics that will be required in the injection molding process, the powder is mixed together with thermoplastic polymers (known as the binder) in a hot state in order to form a mixture in which every metal particle is uniformly coated with the binder. Typically, binders comprise 40% by volume of the feedstock. Once cooled, this mixture is then granulated into pellets to form the feedstock for the injection molding machine. Molding - The next step is the molding of the part in a conventional injection molding machine. The feedstock pellets are gravity fed from a hopper into the machine’s barrel where heaters melt the binder, bringing the feedstock to the consistency of toothpaste. A reciprocating screw forces the material into a two-part mold through openings called gates. Once cooled, the part is ejected from the mold with its highly complex geometry fully formed. If necessary, additional design features not feasible during the molding process (undercuts or cross holes, for example) can be easily added at this stage by machining or another secondary operation. Binder Removal - The ejected as-molded part, known as a “green part”, is still composed of the same proportion of metal and polymer binder that made up the feedstock, and is approximately 20% larger in all its dimensions than the finished part will be. The next step is to remove most of the binder, leaving behind only enough to serve as a backbone holding the size and geometry of the part completely intact. This process, commonly referred to as “debinding”, may be performed chemically (catalytic debinding) or thermally, which in some cases may involve a solvent bath as the initial step. The choice of debinding method depends on the material being processed, required physical and metallurgical properties, and chemical composition. After debinding, the part is referred to as a “brown part”. Sintering - In this process, which is performed in the highly controlled atmosphere of either a batch furnace or a continuous furnace, the brown part is staged on a ceramic setter and is then subjected to a precisely monitored temperature profile that gradually increases to approximately 85% of the metal’s melting temperature. The remaining binder is removed in the early part of this cycle, followed by the elimination of pores and the fusing of the metal particles as the part shrinks isotopically to its design dimensions and transforms into a dense solid. The sintered density is approximately 98% of theoretical. The end result is a net-shape or near-net-shape metal component, with properties similar to those of one machined from bar stock. Of course, if necessary, post-sintering operations such as coining, machining, heat treating, coating, and others, may be performed on the part to achieve tighter tolerances or enhanced properties. When to Use MIM?MIM is an established, highly evolved metal-forming technology, producing intricate components that go into a great variety of end products in countless industries. But, as is true with all metal-forming technologies, MIM is not suited for every application, all the time.To help you understand exactly where MIM emerges as the ideal fit for component fabrication, in this section we offer some general guidelines to use in assessing whether your part is a candidate for the metal injection molding process. You’ll also find some straightforward comparisons between MIM and alternative technologies that will provide further data for your assessment. Finally, we offer a comprehensive, though not exhaustive, listing of the range of materials that are being used in the production of MIM parts.General GuidelinesWhat makes a particular component an ideal candidate for fabrication via MIM? We break down our guidelines into four basic areas: complexity, size, production volume, and final properties.ComplexityMIM offers the same design freedom as plastic injection molding. The more geometrically complex a part is, the more solid the rationale for manufacturing it via the MIM process. Parts may include cross holes, angle holes, internal threads, irregular shapes, splines, undercuts, side holes or grooves, complex contours, orcantilevers.Parts that would usually be made by assembling multiple components can be designed as a single MIM part. Some parts that could not be fabricated via any other process can be made through MIM. A Complexity that would be cost prohibitive to do via multiple machining operations or by casting and then finishing can be achieved cost effectively through MIM processing.SizeIn general, the weight range MIM parts tend to fall within is 0.1 to 250 grams, although above 100 grams the high cost of the extremely fine powders used in the process begins to neutralize MIM’s cost advantages, unless the complexity is extreme. The Parts should have wall thicknesses not less than .13 mm (.005 in.) and not more than 12.7 mm (.5 in.). Due to material flow limitations, the distance from gate to the farthest point on the part should be around four inches. MIM part tolerances are nominally ±0.3%–0.5%, although tighter tolerances can be achieved in some cases if deemed essential.Production VolumeMedium to high volumes of 10,000 to 2,000,000 parts annually are typically needed in order to be able to amortize costs associated with tooling and start-up engineering. The best economic advantages are achieved at the highest quantities, due to the benefits of larger material purchases, multi-cavity tooling, and dedicated production units.Final PropertiesMIM fabrication is ideal where near-full density, high impact toughness, fracture toughness, and fatigue and corrosion resistance are required. And if non-standard material properties are required, these can be developed with new alloy systems.MIM is appropriate for materials that are difficult to machine, materials with multi-phase microstructures, or high work-hardening materials. And it delivers a high-quality surface finish (32 rms or better) and cleaner feature detail than investment casting.Technology ComparisonsThere is a place for each of the traditional metal-forming processes: each has its own strong suits as well as its limitations. But wherever a component fabrication choice exists between MIM and one or more of the other processes, it pays to see how they stack up in a head-to-head comparison.MIM vs. Conventional PM MIM can produce geometries that eliminate secondary operations MIM offers superior density, corrosion performance, strength, ductility MIM can combine two or more PM components into one, reducing part count MIM parts offers superior magnetic performance MIM vs. Machining MIM designs save material and weight MIM provides cost savings through better material utilization—sprues and runners can be reground and reused as feedstock with no compromise to final properties Molding from a single tool eliminates multiple set-up operations Difficult-to-machine materials can be molded into a neat shape MIM vs. Investment Casting MIM can produce thinner wall sections, sharper cutting points MIM produces a better surface finish MIM is better for small-diameter blind and through holes MIM greatly reduces requirements for finish machining MIM produces high volumes of small components at a lower cost, faster lead times Materials RangeThe Metal Injection Molding industry can manufacture an extremely wide variety of metal alloy compositions for use in your application. The alloy families shown below make up a broad representation of the spectrum of alloys which can be/have been produced for various applications. If you do not see the exact alloy or alloy family shown on our extensive list in which you have interest, please contact your supplier in order to see if the alloy or a substitute alloy is available. Working closely with your supplier will enable you to find the best solution for your application.The most common alloy families are:Iron, low-alloy steels, stainless steelsOther alloysAluminum alloys, bio-compatible alloys, carbides, ceramics, cobalt-based alloys, controlled-expansion alloys, copper and copper alloys, hard metals, heavy-metal alloys, magnetic alloys (soft and hard), nickel-based alloys, precious metals, reactive metals, shape-memory alloys, specialty alloys, titanium and titanium alloys, tool steels.

Sintering Furnace

750,000 Per Piece

Ceramic Sintering Furnace

Get Price Quote

We are one of the prominent Manufacturers and Suppliers of Ceramic Sintering Furnaces. Made in accordance with industrial norms, our entire range is quality assured, tested and reliable. It is excellent for carrying out continuous operation with any hitch. Buyers can purchase Ceramic Sintering Furnaces from us as per requirement. We offer them in varied specifications and provide customized solutions as well. Buyers can obtain Ceramic Sintering Furnaces from us in single and double stage

Tube Type Sintering Furnace

370,000 Per Piece

1 Piece (MOQ)

High vacuum sintering furnace

Get Price Quote

Sintering is a heat treatment process, for bonding particles into a coherent; predominantly solid often occurs on the atomic scale. It leads to improved strength. This process required for many different parts and applications, including powder metallurgy, metal injection molding (MIM) and 3D printing components of various types or beading applications including abrasives.

Abrostate-1450HT Dental Zirconia Sintering Furnace

Get Price Quote

Sintering Furnace

Get Price Quote

Finding application in ferrite sintering applications, Sintering Furnace offered can work with maximum temperatures of 1300oC and perfectly supports sintering process involving formation of solid material mass through heat without melting the material to point of liquification.

Continuous Sintering Furnace

Get Price Quote

Sintering Furnace

Get Price Quote

Features It features molybdenum disilicide heating elements which provide clean consistence & reliable results. It can be programmed with 100 programs with 20 steps each. It has a quick fring program with a cycle of upto 1.5 hours with high temperature. It can sinter 75 units simultaneously with 3 stackable trays. Comes with SD cards which allows users to edit their fring programs

Sintering Furnaces

Get Price Quote

For the processing of advanced materials like graphene, carbon nanotubes, metal oxides, technical ceramics, carbon materials etc and to answer the challenge of the research & development community to produce the finest, high temperature, high vacuum and controlled atmosphere furnaces in the industry, simco partnered with international companies to bring heat treatment solutions.

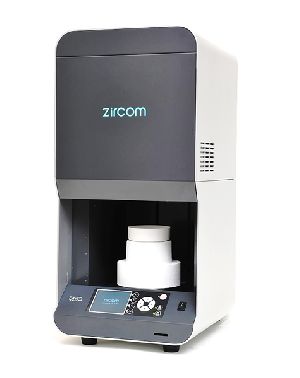

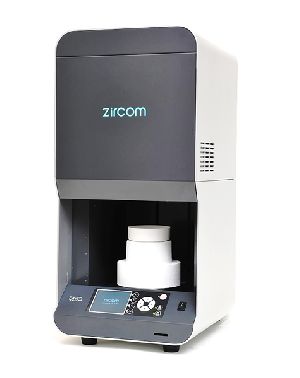

Zircom DENTAL Sintering Furnace

Get Price Quote

Zircom Sintering Furnace Zircom Sintering Furnace delivers delicacy and beauty to your zirconia. it is also user-friendly with very simple operation. The unit is applicable to various types of zirconia materials. Features It features molybdenum disilicide heating elements which provide clean consistence & reliable results. It can be programmed with 100 programs with 20 steps each. It has a quick fring program with a cycle of upto 1.5 hours with high temperature. It can sinter 75 units simultaneously with 3 stackable trays. Comes with SD cards which allows users to edit their fring programs

Continuous Type Sintering Furnace

Get Price Quote

Product Description Agnee Engineering & manufactures Continuous Sintering Furnace (these can be continuous pusher furnaces or continuous mesh belt furnaces based on temperature) or Batch Sintering Furnaces for powder metallurgical and ceramic applications. These furnaces work under controlled atmospheres, usually hydrogen or cracked ammonia based, and have a robust leak tight construction. Continuous Sintering Furnaces can be completely automated. Standard operating temperatures are upto 1750°C. Please get in touch for higher requirements. Product Specification Minimum Order Quantity : 1 Piece(s)

Sintering Furnaces

Get Price Quote

Lakshmi Vacuum Technologies are pioneers in the market for manufacturing and supplying Vacuum Sintering Furnace. These furnaces have numerous heat treating applications because they apply vacuum as well as inert atmospheres. The product is fabricated under the expert supervision of our professionals that guarantee its durability and superior functionality. They are also used for different high - temperature processes such as carburisation, re-crystallisation, silicon infiltration, nitridation, vacuum sintering or metallisation .Vacuum sintering furnace is available in different sizes and can be customized for catering the client’s needs at very nominal prices.

High Temperature Microwave Sintering Furnace

Get Price Quote

We are an eminent Manufacturer and Supplier of High Temperature Microwave Sintering Furnaces. The Microwave Sintering Furnaces we make available come with digital display of power and temperature and non-contact temperature monitoring. We hold the expertise of delivering bulk orders of the Microwave Sintering Furnaces within the promised timeframe. Details : This is an advanced Microwave Sintering Furnace with State-of-the-Art Control system and high microwave power to sinter larger samples. We recommend this system for users who have graduated with their basics in Microwave Sintering and want to move on to the level Industrial Microwave Sintering Applications. This system enables the user to sinter a broad range of materials in varied atmospheric conditions, it ideally suits industries looking at replacing their current heating systems with microwave sintering furnaces, AND hence it serves as a perfect bridge between lab experiments and industrial production. Salient Features : Throughput of the furnace ranging from 50 to 1000 kg/day Typical Cross Section of 200 to 1000mm (W) and 150 to 400mm (H) Maximum Process Temperature upto 1700 deg.C Non-Contact Temperature Monitoring Installed Microwave Power of 5.8 kW to 250 kW Conveying System with controls for Speed and position Step-less Power Control using Microcontroller Module Digital Display of Power and Temperature Highly integrated Interlocks State of the Art Process Control using High End PID controller Industrial PLC with touch screen controls Inert/Reducing/Oxidizing Atmospheric Sintering

Sintering Furnaces

Get Price Quote

Dental furnace by Bionics Scientific is definitely an example of excellent engineering and especially designed for sintering of Zirconia materials. Competing price and performance ratio as compared to any other brand available on Indian market today, it fulfills all dental furnace jobs very efficiently and a must have equipment for dental clinics and laboratories. Intelligently designed and manufactured with advanced technology, our dental furnace lets you experience tremendous muffle heat distribution and steady heat rise speed. It features fully programmable operation resulting easy and fast operation. With 1700°C maximum temperature, 1650°C working temperature, high purity alumina fiber internal chamber, it proves to be perfect solution for variety of dental heat treatment applications. The unit is fully programmable and driven by touch screen menus, which makes sintering work easier and relaxing.

Sintering Furnaces

Get Price Quote

Sintering Furnaces, Injection Molding Machines, MATERIALS

Sintering Furnace

Get Price Quote

Sintering Furnace, Furnaces, Viscometer, analyzers, Capacitance Decade Box

Sintering Furnace

Get Price Quote

Sintering Furnace, Furnaces, Viscometer, coal crushing equipment

high temperature sintering furnaces

Get Price Quote

we are offering High Temperature Sintering Furnaces. Therelek is one of the leading manufacturers & suppliers of high temperature sintering furnaces from India.

Vacuum Sintering Furnace

Get Price Quote

Vacuum Sintering Furnace, plasma nitriding furnace, Vacuum Annealing Furnace

Sintering Furnace

Get Price Quote

Sintering Furnace, hardening furnace, heat treating furnaces

Pellet Sintering Furnace

Get Price Quote

Pellet Sintering Furnace, Batch Type Furnace

Vacuum Sintering Furnace

Get Price Quote

Vacuum Sintering Furnace, vacuum hardening furnace, Vacuum Brazing Furnace

Sintering Furnaces

Get Price Quote

Sintering Furnaces

Sintering Furnaces

Get Price Quote

Sintering Furnaces, heat treating furnaces, electrode salt batch furnace

Sintering Furnace

Get Price Quote

Sintering Furnace, Carbon Dioxide Heater, hopper heaters, Tubular Heaters

Sintering Furnace

Get Price Quote

Sintering Furnace, Heating Oven, Bogie Hearth Furnace

Microwave Sintering Furnace

Get Price Quote

Microwave Sintering Furnace, DC Magnetron Sputtering System