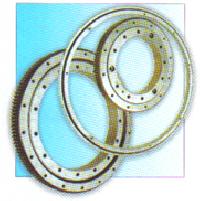

cylindrical roller slewing bearing

10,000 Per Piece

10 Piece (MOQ)

Slewing Ring Bearings

Get Price Quote

From Surat(India), we are providing a lot of products having quality and cost-effective prices. Our Slewing Ring Bearings have strong structure, corrosion resistant surface & long working life. The Slewing Ring Bearings can be availed in different sizes with diameters varying between 500-5000 mm. Stay rest assured for the products that we offer as they will remain damage free. For this, we make use of only premium packaging material for the packing of the products.

Best Deals from Slewing Bearings

Vestas V27 Slewing Bearing

Get Price Quote

5 Piece (MOQ)

Slewing Bearings

Get Price Quote

We are proud to be one of India’s few slew ring bearing manufacturers who have developed these products indigenously. We can guarantee that our slew ring bearings match global standards and are competitively priced.

Non Geared Slewing Bearing

Get Price Quote

When it comes to Non Geared Slewing Bearing, Signet International is recognized as one of the reliable Manufacturers, Exporters and Traders. We manufacture Non Geared Slewing Bearing using the finest metal and advanced technology. These are made to perfection, and thus exhibit tensional strength. The esteemed clients can avail these Non Geared Slewing Bearings at the market leading prices from us. Technical Specifications

Tower Crane Slewing Bearing

75,000 Per Piece

Slewing Bearings

Get Price Quote

Design of the support structure the slewing ring has a limited axial stiffness: the diameter is large compared to the cross section. It must be mounted on a machined supporting base, ensuring sufficient stiffness with regard to the loads to be transferred. This makes it possible to ensure an even distribution of stresses and to avoid any deformation during operation, which would be harmful to the good working of the bearing. Therefore, it is necessary to use supporting bases with a minimum thickness not less than the values indicated in the table above. The width of the supporting surfaces is to be at the least equal to that of the ring.

Slewing Bearings

45,000 Per Piece

5 Piece (MOQ)

Slewing Ring Bearing

1 - 1,000 Per Piece

1 Piece (MOQ)

We are offering slewing ring bearing MADE IN ITALY

Mobile Tower Crane Slew Ring

Get Price Quote

Slewing Bearings

Get Price Quote

To accommodate radial, axial and moment loads in single or combination direction Slewing Bearings are which are in large size. This bearing can perform oscillating and rotational movements. It consist of inner ring and outer ring and rolling elements like cylindrical or ball rollers. The raceway in the rings are precision finish and hardened. This Slewing Bearings are re lubricated by grease fittings to minimize operating cost and maintenance cost. Slewing Bearing is also available with Bearing dealers in Qatar.

Slewing Bearing

Get Price Quote

slewing bearings are machine elements which absorb all axial and radial forces and the resulting tilting moments in a single self-retaining and ready-to-install unit. Their low profile and an excellent weightperformance ratio, open center, and the possibility of an integrated gearing make Rotek slewing bearings ideal structural components. Slewing ring bearing solutions are ideal for optimal economy in a given envelope dimension; for heavy-duty applications requiring significant load-carrying capacity; for designs where precise positioning is critical; and for the unique requirements of wind turbines. Our slewing ring bearings offer total solutions for the most demanding specifications in a variety of applications, including: Aerospace and Engineering Heavy equipment Industrial machinery Medical systems Renewable energy Semiconductor manufacturing equipment

Slewing Bearings

Get Price Quote

Self-aligning ball bearings have two rows of balls, a common sphered raceway in the outer ring and two deep uninterrupted raceway grooves in the inner ring. They are available open or sealed. The bearings are insensitive to angular misalignment of the shaft relative to the housing (fig. 1), which can be caused, for example, by shaft deflection.

Slewing Bearings

45,000 Per Piece

Slewing Bearings

Get Price Quote

we offer slewing bearing is widely used in different industries. It is suitable for hoisting machine (truck crane, tower crane, etc.), construction machinery (excavator, loading and unloading machine), transporting machine, material processing machine, metallurgy machinery, food processing machine, military product (tanks, anti-aircraft gun, radar, missile launcher, etc.).

Slewing Ring Bearings

Get Price Quote

Avail from us the best Slewing Ring Bearings that have no match in the market for their performance and durability. Manufactured as per industrial standards, the Slewing Ring Bearings are tested Stringently to assure their quality. We can offer the Slewing Ring Bearings in the following types of designs as mentioned below : Ball Type Single RowFlange TypeWithout GearWith External GearWith Internal Gear Ball Type Double RowWithout GearWith External GearWith Internal Gear. Roller Type Single RowWith External GearWith Internal Gear. Useful For Mobile CraneTower CraneShipboard CraneConstruction CraneContainer Handling CraneLoading and Cargo Handling

Slewing Bearings

Get Price Quote

Slewing Bearings

Get Price Quote

Slewing Bearings

Get Price Quote

Slewing Bearings are Large-size rolling bearings which can accommodate axial, radial and moment loads either single or in combination direction. They can perform both movements oscillating as well as rotational. Basically a slewing bearing consists of inner ring, outer ring and rolling elements – balls or cylindrical rollers. The rolling elements are separated by polyamide spacers. The rings, which usually incorporates a gear are provided with holes to accommodate attachment bolts. The holes may be threaded. Generally, only the raceways in the rings are hardened and precision finish. Integral seals keeps the lubricant in, and contaminants out of the bearing. Slewing bearings are re-lubricated through grease fittings to reduce maintenance and operating costs.

Slewing Bearings

25,000 Per Piece

1 Piece (MOQ)