sludge dewatering system

Get Price Quote

We use premium-packaging materials to safeguard our products from mechanical and environmental conditions. For our patrons, we offer customized packaging solutions as well. As a customer-focused firm, we strive hard to delight them with high quality range of products that are the perfect outcome of premium raw material and modern work methods. Features : High performance Long working life Robust design

sludge dewatering machine

300,000 Per Piece

1 Piece(s) (MOQ)

Best Deals from Sludge Dewatering Machine

sludge dewatering machine

325,000 Per piece

1 piece (MOQ)

we “M/s Constraarch-enviro” are manufacturing, importing and exporting an assorted range of Water Treatment Equipment, Pollution Control System, Water Filter, Effluent Treatment Plant, etc

Sludge Dewatering

Get Price Quote

Wastewater sludge dewatering is a crucial process in wastewater treatment plants and various industrial sectors that generate sludge as a byproduct of their operations. Sludge is a semi-solid mixture of water, organic matter, and inorganic particles that remains after the wastewater treatment process. Dewatering involves removing a significant portion of the water content from the sludge, transforming it from a wet, slurry-like substance into a more manageable and less voluminous material. This process holds substantial importance for several reasons: Volume Reduction: The primary benefit of dewatering is the significant reduction in the volume of sludge. Removing water from sludge leads to a reduction in its weight and volume, which lowers transportation and disposal costs. This is particularly important as sludge disposal can be expensive, and reducing the volume makes it more cost-effective to handle and transport. Cost Savings: As mentioned, dewatering reduces the weight and volume of sludge, which translates to lower transportation and disposal costs. Since many wastewater treatment plants and industries have to manage large quantities of sludge, even a slight reduction in volume can result in substantial cost savings over time. Resource Recovery: Depending on the specific characteristics of the dewatered sludge, it might be suitable for further processing to recover valuable resources. For instance, some dewatered sludges can be used as fertilizers, soil conditioners, or even converted into biogas through anaerobic digestion, thus turning waste into a resource

sludge dewatering machine

Get Price Quote

1 Piece (MOQ)

Sludge dewatering is the process of separation of components of solid and liquid sludge to minimize the sludge disposal.Sludge dewatering equipment is not intended to treat the sludge or liquid but; it only separates the liquid components & solid components so it will get easier & cost-effective to handle the separate phases of the disposal. Once the Final sludge has been dewatered, then the liquid is treated in ETP/STP & solid sludge is disposed.The main purpose of the Sludge dewatering machine is to minimize handling and disposal. Sludge dewateringpress is the most cost-effective method of dewatering and hence helps to sustain the environmental objectives of the company.

sludge dewatering machine

600,000 Per Piece

1 Piece(s) (MOQ)

screw sludge press dewatering machine

Get Price Quote

sludge dewatering machine

800,000 - 5,500,000 Per Unit

1 Unit (MOQ)

Bag Sludge Dewatering Machine

50,000 - 150,000 Per Piece

1 Piece(s) (MOQ)

sludge dewatering machine

Get Price Quote

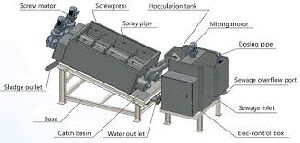

To fulfill the dream of make in India, and focusing on independent technology innovation. Under the cooperation with Tongji University, TECHASE have successfully developed the new generation of sludge dewatering technology -multi-plate screw press, a screw type sludge dehydrator that is much more advanced in very aspects than belt presses, centrifuges, plate-and-frame filter presses, etc. It features clogging-free, wide range of applications, low energy consumption, simple operation & maintenance.Details The Multi-Plate Screw Press utilizes the dewatering principles of force- water homo direction thin layer dewatering, proper pressure and extension of the sludge dewatering path. More advanced than the traditional dewatering equipment which are easily blocked, unsuitable for low concentrated sludge and Oily sludge, of high consumption and difficult to operate, will eliminate these problems and of higher efficiency and power saving The equipment is controlled by the electric control cabinet, allows automatic continuous operation of sludge flocculation, thickening, dewatering and the filtrate discharge.

sludge dewatering machine

100,000 - 350,000 Per piece

1 Piece (MOQ)

A sludge dewatering machine is a device used to remove water from sludge, which is a semi-solid mixture of solid waste and water. Sludge is typically generated during industrial processes such as wastewater treatment, food processing, and mining. Sludge dewatering machines use a variety of techniques to separate water from the solid waste. Some common types of sludge dewatering machines include belt filter presses, centrifuges, screw presses, and vacuum filters.

sludge dewatering system

Get Price Quote

We are into manufacturing and supplying the finest quality and the most efficient Sludge Dewatering System in Haryana, India. It is fabricated by our team of professionals having years of experience using the latest technology. The System is fully automatic assuring longer service life. It is made as per the international norms with inertia platform and vibration isolating dampers to ensure smooth operation. One can obtain it from us at nominal rates. The advantages of the Centrifuge Machine : Nominal time for removal of cake Dual increase in the total production capacity Slight cake handling loss Manual contact with cake is avoided Can be easily mounted Cake spillage on the floor is nil More volumetric charge per machine Easy preservation of the basket Even allocation of slurry

sludge dewatering machine

Get Price Quote

Filter Press The filter press basically consists of a number of chamber filter plates (also referred to as recessed filter plate pack) mounted vertically on and between two sidebars or suspended from an overhead support beam. A filter cloth is mounted over each of the two faces of the filter plate. The cloth is joined at the feed eye by an impervious sleeve or tube also known as a barrel neck. Filter Press Feed Cycle:- Step 1 : Sludge is fed into the filter press by a suitable pumping system and passes through the feed eye of the succeeding plates along the length of the plate pack until all chambers are full of slurry. This is known as the fast fill portion of the filter cycle. Step 2 : Flowing under pressure, the solid particles begin to deposit on the surface of the filter cloth forming the initial layer of filter cake referred to as the pre-coat. Once applied, this pre-coat layer becomes the actual filtering medium. Step 3 : As filtering continues the cake thickness gradually increases, until the adjacent filter cake in each chamber touch or bridge. At this point of the filter cycle, the dewatering phase enters into final cake consolidation to achieve maximum cake dryness. Filter Cloths The filter cloths are woven fabrics using monofilament or multifilament synthetic fibers or a combination of both. The most commonly used materials are polypropylene, polyester, and nylon. Filter cloths are primarily selected for filtration, strength, and cake release properties. Sludge Drying Bed Sludge drying beds may be used for dewatering sludge. Drying beds are confined, under drained and shallow layers of sand over gravel on which wet sludge is distributed for draining and air drying. Drying beds have proved satisfactory at most small and medium-sized sewage treatment plants located in warm, dry climates.

sludge dewatering machine

300,000 Per Piece

2 Piece (MOQ)

Vegetable De-Water Machine

Get Price Quote

Description Machine body is made of SUS304 sandblasted stainless steel.Machine comes with PLC control panel, which sets dehydrating time and rotation speed, makes running smoothly.

sludge dewatering systems

Get Price Quote

A sludge dewatering system comprising a moving foraminous belt (10) having a horizontal conveying run on which sludge is carried to permit drainage of water therefrom through the belt.

Petrochemical Sludge Dewatering Machine

260,000 Per Piece

sludge dewatering machine

650,000 Per Piece

1 Piece (MOQ)

sludge dewatering systems

Get Price Quote

A sludge dewatering system comprising a moving foraminous belt (10) having a horizontal conveying run on which sludge is carried to permit drainage of water therefrom through the belt.

Effluent Treatment Sludge De-Watering machine

Get Price Quote

Kombelt-Mono Is suitable for all types of etp and stp sludge, like, chemical, biological, primary, secondary, or mixture of them etc..Even oily sludges are also effectively handled by this range of filters. They come in 4 different sizes catering from 10 cu.m to 400 cu.m/day of sludge flow. They are fully automatic needing very little manpower supervision or intervention. They are engineered in a way that would require very least maintenance and is carried out very easily.