High Rate Solid Contact Clarifier

25,000 - 500,000 Per Piece

5 Piece (MOQ)

solid contact clarifier

605,000 Per Set

1 Set (MOQ)

Best Deals from Solid Contact Clarifiers

solid contact clarifier

450,000 Per Piece

1 Piece (MOQ)

HRSCC- High Rate Solid Contact Clarifier

Get Price Quote

Its designed to handle turbidity and to remove suspended solids. These units have an ability to offer turbidity less than 50 NTU at the outlet of clarifier.Features : Constructed either in a steel tank /concrete basin A unique rotor-impeller combination has made it possible to control mixing and slurry recirculation to accommodate changes in water characteristics. Advantages : In HRSCC Flocculation, coagulation & settling processed in a single tank i.e. HRSCC Tank. It can accommodate a wide range of flow rates and solids variations. The unit produces a very dense sludge that minimizes sludge handling. Rapid sludge settling and thickening Minimizes dewatering equipments costs Minimum Operator attention. Application : Colour removal Primary treatment of waste water.

High Rate Solid Contact Clarifier

Get Price Quote

Our company is reckoned amongst the trustworthy providers of an unmatched range of High Rate Solid Contact Clarifier. Our clarifier is a high rate recirculation type clarifier that is used for the purpose of clarification, silica reduction, lime softening or organics reduction of water and wastewaters containing suspended solids, color and higher clarified water quality. It also increases the over flow.

High Rate Solids Contact Clarifier

Get Price Quote

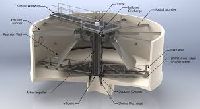

THE EIMCO-K.C.P. LTD Solids Contact Reactor Clarifiers are basically divided into two different classes HRC and HRB mechanisms. HRC is the high rate column supported Reactor Clarifier of size ranging from 15m to 75m diameters. HRB is a high rate bridge mounted Reactor Clarifier supplied in sizes ranging from 3m to 25m diameters. The high rate Solids-Contact Reactor Clarifier operates with the raw influent liquid being brought into immediate contact with a large circulating volume of relatively dense previously formed flocculate and precipitate. The mixture of raw influent liquid and re circulated slurry is sent upward into the reaction cone with 75-90% being returned to recirculation with the incoming raw water. The remaining 10-25 % passes under the cone and into the clarification zone. Once in the clarification zone, the solids settle to the tank floor with the clarified liquid moving into the effluent launder and exiting tank The BFR and CF Reactor Clarifiers are applied to processes where longer detention times within the feed well and no solids recycle are necessary or requested by customer. The detention times are considerably longer than those offered by higher rate solids-contact units and are necessary for proper flocculation.

solid contact clarifiers

Get Price Quote

High Rate Solid Contact Clarifier (HRSCC) is mostly used in applications wherein a large variation in the inlet conditions has to be tolerated by the system. High Rate Solid Contact Clarifier (HRSCC) produces an effluent of the highest quality in minimum time and space and using a minimum amount of chemicals.

High Rate Solid Contact Clarifiers

Get Price Quote

We are offering high rate solid contact clarifiers. the solid contact clarifiers is designed to remove the suspended solids and high turbidity in the water. These systems contains dosing system, clarifloculator tank inbuilt with settling zone. These clarifiers have the ability to offer turbidity less than 50 ntu at the outlet of clarifier.

solid contact clarifiers

Get Price Quote

The design features of the solids contact type clarifier provide the three zones necessary for proper clarification: Rapid mix zone, where raw water, recirculated precipitates and fresh reagents are rapidly mixed together. Slow mix zone,where gentle mixing permits floc formation and brings the floc into intimate contact with the suspended impurities.

solid contact clarifiers

Get Price Quote

High Rate Solid Contact Clarifier are the most popular clarifiers in field of water treatment. They are preferred more than any other clarifier because they can handle large flow rate and provide better effluent quality outlet than other clarifiers.

solid contact clarifiers

Get Price Quote

HRSCC is mostly used in applications wherein a large variation in the inlet conditions has to be tolerated by the system. After coagulation andor flocculation in the sludge blanket units, the incoming water passes through the suspended layer of previously formed floc. "Solids-contact" refers to units in which large volumes of sludge are circulated internally. The term also describes the sludge blanket unit and simply means that prior to and during sedimentation the chemically treated water contacts previously coagulated solids. Solids-contact, slurry pool units do not rely on filtration as in sludge blanket designs.

solid contact clarifiers

Get Price Quote

The High Rate Solid Contact Clarifier usually called as HRSCC is used mostly wherein the incoming load conditions vary. Much wider range of water qualities can be handled in the HRSCC Clarifier. The principle is based on mixing existing floc with the incoming effluent, to create a dense floc, which can be easily settled down

High Rate Solid Contact Clarifier

Get Price Quote

The high rate solid contact clarifier usually called as HRSCC is used mostly wherein the incoming load conditions vary. Much wide range of water qualities can be handled in the HRSCC Clarifier. Application Colloidal Silica Removal Waste Water Treatment Heavy Metal Recovery Advantages The solids contact type clarifier is a high rate water treating clarifier, which produces treated water of highest quality with minimum time, space and chemicals. Simple and straight forward operation requiring less operator attention and minimum maintenance Minimum building space requirements and building height clearances.

High Rate Solids Contact Clarifier

Get Price Quote

High Rate Solids Contact Clarifier is widely used for clarification of raw water and wastewater. Incorporates the design of internal solid recirculation thereby optimising the chemical consumption and making it more economical than conventional filter.

High Rate Solid Contact Clarifier

Get Price Quote

Techno High Rate Solids Contract reactor clarifiers have general application for Raw Water Treatment and for industrial process. Improved operating efficiencies keep operating costs to a minimum. Solid Contact Clarifier Water Treatment units effectively clarify and soften raw or process water for re-use.

High Rate Solid Contact Clarifier

Get Price Quote

HRSCC uses turbulence and high velocity to reduce silica load in the water apart from deduction of suspended impurities and turbidity. HRSCC requires lesser area and process time and thereby, reduces the initial civil cost of the plant.

solid contact clarifiers

250,000 Per Units

solid contact clarifiers

Get Price Quote

THE EIMCO-K.C.P. LTD Solids Contact Reactor Clarifiers are basically divided into two different classes HRC and HRB mechanisms. HRC is the high rate column supported Reactor Clarifier of size ranging from 15m to 75m diameters. HRB is a high rate bridge mounted Reactor Clarifier supplied in sizes ranging from 3m to 25m diameters.

solid contact clarifier

Get Price Quote

surface aerator, Oil Skimmer, Wastewater Treatment Equipment

High Rate Solid Contact Clarifier

Get Price Quote

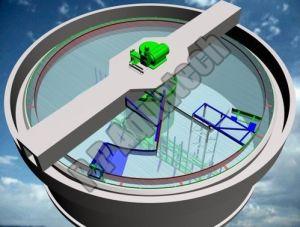

We are manufacturing world class Solid Contact Clarifiers that have capacity to act as both an improved flocculation device and high rate chemical precipitator. Here, mixing, internal solids recirculation, gentle flocculation and gravity sedimentation are all combined within single unit. The solid contact clarifiers mix the influent flow with previously settled solids within the draft tube. In this, the gentle mixing within the reaction well promotes agglomeration of floc particles and chemical precipitates. Then, the aggregated solids settle out more quickly in the clarification area. In the solid contact clarifiers, clarified overflow is removed through a radial launder system that draws water from the complete surface area to avoid solids carryover caused by uneven velocity currents. This Clarifier is a high rate, solid contact, sludge recirculation in minimum space and using a minimum amount of chemicals, produces an effluent of the highest quality. Used for clarification, lime softening, Silica reduction or organics reduction of water & waste waters containing suspended solids, colors and organic impurities. It provides means for chemical addition and mixing, flocculation and up flow clarification in a single unit.The mechanism would be of centrally driven type with fixed full bridge spanning the tank diameter with necessary walkway and handrails to access drive unit at the centre.This Clarifier is a high rate, solid contact, sludge recirculation in minimum space and using a minimum amount of chemicals, produces an effluent of the highest quality. Used for clarification, lime softening, Silica reduction or organics reduction of water & waste waters containing suspended solids, colors and organic impurities. It provides means for chemical addition and mixing, flocculation and up flow clarification in a single unit. The mechanism would be of centrally driven type with fixed full bridge (Lattice type) spanning the tank diameter with necessary walkway and handrails to access drive unit at the centre. Two more truss fabricated structures shall be placed at 90º to the bridge spanning the tank diameter to help suspend and hold the drat tube and detention hood. Clarifier Drive unit consisting of Drive head (Worm shaft & worm gear) connected to Gear Box by Chain & sprockets and the Gear box connected to Motor by Love joy Coupling. Main Vertical solid inserted into the Clarifier Drive head gear bore and keys locked, suspended freely, flange facing downwards. An intermediate Scraper arm shaft made out of Heavy duty pipe suspended from the vertical shaft. Two Scraper arms, rigidly fabricated to sweep the tank floor with Scraper blades, Neoprene Rubber squeezes and Strips to hold Squeezes. Suitable Central Sludge well scraper. Recirculation system will be placed between the top and bottom portions of the bridge. Main Nylocast driven gear bolted to the drive bearing and seated on the main vertical shaft between the aforesaid pair of bearings. Driven gear connected to the drive gear which is mounted on the Gearbox output shaft and input shaft connected to Motor by coupling. Recirculation shaft made out of heavy duty pipes and bolted to the driven gear bottom face. Impeller for recirculation bolted to the shaft. Suitable diameter of Draft tube for dozing and mixing suspended from the bridge bottom and properly reinforced. Inlet nozzle with flange at the bottom tangentially placed for Feed entry. Suitable diameter of Detention hood made out of FRP fixed for flocculation. Features: Low energy mixing for chemical reactions & formation of floc particles Unique low shear high volume impeller Gravity sedimentation clarification and enhanced flocculation in one unit Consumes less chemical input Low horsepower requirements Requires less space than conventional flocculation and sedimentation train Considerable savings in terms of tank age, civil work, and operational costs Applications: Pretreatment to conventional filtration Acid mine drainage Surface water clarification Cold lime softening Color removal Pretreatment to membranes Tertiary wastewater treatment Phosphorous removal Heavy metals removal