Solids Separation Unit

180,000 Per Units

1 Units (MOQ)

Liquid-Liquid Extraction Unit

160,000 - 550,000 Per Piece

1 unit (MOQ)

This is a semi-batch unit designed for liquid-liquid extraction as a means of separation. Liquid to be extracted should be treated with solvent of different density. A liquid mixture is poured in the extraction vessel. Solvent in the reactor is boiled and condensed, and passed to the extraction vessel, from where liquid is extracted and is mixed with the solvent and passes to the reboiler. The process is repeated until extraction is complete. Solution is again evaporated to obtain the extract. The unit is complete with spherical vessel, heating bath, condenser, reflux divider, extraction vessel, and necessary pipelines and valves. The unit can be supplied with solvent feed arrangement either from the top or from the bottom, or with both arrangements. The unit is available in vessel size of 10, 20, 50, 100 Ltr.

Best Deals from Solid Liquid Extraction Unit

Solid Liquid Extraction Unit

Get Price Quote

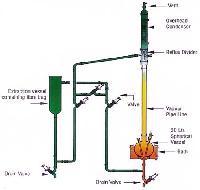

This operation involves preferential solublizing of one or more soluble constituents (solutes) of a solid mixture by a liquid solvent. The unit described here is for a semi-batch operation. The solid to be extracted is put inside a glass fiber bag and placed in an extraction vessel. Solvent from the re-boiler is continuously evaporated, condensed and circulated through a reflux divider by means of piping network and valves. When desired steady concentration of solute is achieved in the solution the operation is discontinued. The solution is drained off and collected for further use. After charging fresh solid in fiber bag and solvent in re-boiler, the cycle can be restarted again. The unit is available in vessel sizes of 10, 20, & 50L and is suitable for operation under atmospheric pressure.

Apricot Liquid Extract

550 - 750 Per Kilogram

1 Kilogram (MOQ)

It is a viscous oil that is pale yellow to golden yellow in color. Apricot Kernel Oil is known to resemble the sebum naturally found in human skin, making it rich in cleansing, conditioning, and moisturizing properties.

Solid-Liquid Extraction Unit

Get Price Quote

ALPHA CHEM-1311 Solid-Liquid Extraction Unit Contaminants may be present sorbed in the solid particles of the soil. Solid-liquid extraction allows these contaminants to be removed from the soil. Depending on the contaminant and the type of soil, a suitable solvent needs to be selected for this process. One field of application for example, is the separation of organic contaminants that are present sorbed in fine solid particles. Solid-liquid extraction may take place after these fine particles have been separated by a hydrocyclone in the ex-situ treatment of contaminated soil. The fundamental principle of solid-liquid extraction can be learned with the CE 630. The temperature of the solvent can be adjusted. Thus, it is possible to investigate the effect of this parameter on the separation process. The principle of counter current in solid-liquid extraction: 1 Extract outlet, 2 Extraction residue, 3 Extractant inflow, 4 Extraction material inflow, A Path of the extract, B Path of the extraction material

Arnica Liquid Extract

550 - 750 Per

1 Kilogram (MOQ)

Calendula oil is a great moisturizer for all types of skin. The oil works wonders on dry or split skin and soothes the cracked area. The essential oil of Calendula is high in triterpenoid content which heals dry skin, eczema, and hemorrhoids. The oil's anti-bacterial properties fight skin infections.

Solid Liquid Extraction Plant

Get Price Quote

We are one of the trusted companies in India, which is manufacturer and exporter of Solid Liquid Extraction Unit. The unit we provide is based on latest technology, which is mechanically designed and tested by our engineers so that it can give the best of its performance. Our unit is fully customized to meet our client’s requirement.Process Description :This operation involves preferential solubilising of one or more soluble constituents (solutes) of a solid mixture by a liquid solvent. The unit described here is for a semi-batch operation. The solid to be extracted is put inside a glass fibre bag and placed in an extraction vessel. Solvent from the reboiler is continuously evaporated, condensed and circulated through a reflux divider by means of piping network and valves.When desired/ steady concentration of solute is achieved in the solution the operation is discontinued. The solution is drained off and collected for further use. After charging fresh solid in fibre bag and solvent in reboiler, the cycle can be restarted again.The units are available in vessel sizes of 10, 20, & 50 Ltr and are suitable for operation under atmospheric pressure.Features : Easy maintenance Sturdy structure Fine functionality

Solid Liquid Extraction Unit

Get Price Quote

This operation involves preferential solublising of one or more soluble constituents (solutes) of a solid mixture by a liquid solvent. The unit described here is for a semi-batch operation. The solid to be extracted is put inside a glass fiber bag and placed in an extraction vessel. Solvent from the reboiler is continuously evaporated,condensed and circulated through a reflux divider by means of piping network and valves. When desired steady concentration of solute is achieved in the solution the operation is discontinued. The solution is drained off and collected for further use. After charging fresh solid in fiber bag and solvent in reboiler, the cycle can be restarted again. Solvent Extraction units are available in vessel sizes of 10, 20, & 50L and is suitable for operation under atmospheric pressure.

Solid Liquid Extraction Unit

40,000 Per 45000 Set

10 Set(s) (MOQ)

we offer Solid Liquid Extraction Unit. This operation involves preferential solublizing of one or more soluble constituents (solutes) of a solid mixture by a liquid solvent. The unit described here is for a semi-batch operation. The solid to be extracted is put inside a glass fiber bag and placed in an extraction vessel. Solvent from the re-boiler is continuously evaporated, condensed and circulated through a reflux divider by means of piping network and valves. When desired/ steady concentration of solute is achieved in the solution the operation is discontinued. The solution is drained off and collected for further use. After charging fresh solid in fiber bag and solvent in re-boiler, the cycle can be restarted again. The unit is available in vessel sizes of 10, 20, & 50L and is suitable for operation under atmospheric pressure.

Solid Liquid Extraction Unit

Get Price Quote

LEACHING EXPERIMENT (SOLID LIQUID EXTRACTION), Solid liquid extraction unit , We also manufacture the equipments and control systems for sugar industries mainly mill automation, boiler instrumentation, prd stations and embibition water control system.

Solid Liquid Extraction Unit

Get Price Quote

We are into offering solid liquid extraction unit, which is a semi-batch unit specially designed for solid-liquid extraction. Our range of solid liquid extraction units is fabricated using superior quality components, which ensure better performance. Moreover, this unit can be supplied with solvent feed either from the top/or bottom, or with common arrangement.

Solid Liquid Extraction Unit

Get Price Quote

Solid Liquid Extraction Unit Contaminants may be present sorbed in the solid particles of the soil. Solid-liquid extraction allows these contaminants to be removed from the soil.. Depending on the contaminant and the type of soil, a suitable solvent needs to be selected for this process. One field of application for example, is the separation of organic contaminants that are present sorbed in fine solid particles. Solid-liquid extraction may take place after these fine particles have been separated by a hydrocyclone in the ex-situ treatment of contaminated soil. The fundamental principle of solid-liquid extraction can be learned with the CE 630. The temperature of the solvent can be adjusted. Thus, it is possible to investigate the effect of this parameter on the separation process. The principle of counter current in solid-liquid extraction: 1 Extract outlet, 2 Extraction residue, 3 Extractant inflow, 4 Extraction material inflow, A Path of the extract, B Path of the extraction material Chemical Engineering Laboratory lab equipment manufacturers,exporters and Chemical Engineering Laboratory Lab suppliers

Solid Liquid Extraction Unit

Get Price Quote

The setup consists of Bonnotto type extractor of slotted circular plates arranged one above the other in opposite radial opening. The solids are introduced at the top through a hopper spread over the top plate by a rack and pushed to slot to fall to the next plate below and so on to the bottom of the column. The solvent is introduced near the bottom of the column and it flow upward counter-currently to the solids. A pump supplies the solvent and flow rate is monitored by means of a Rotameter. At the bottom of column a screw conveyor arrangement is done to remove the extracted solids driven by means of an electric motor. Solvent feed tank is kept in a bath fitted with heater and digital temperature controller is used to maintain the constant temperatur

Solid Liquid Extraction Unit

Get Price Quote

Solid Liquid Extraction Unit Solvent extraction is usually used to recover a component from either a solid or liquid. The sample is contacted with a solvent that will dissolve the solutes of interest. Solvent extraction is of major commercial importance to the chemical and biochemical industries, as it is often the most efficient method of separation of valuable products from complex feedstock’s or reaction products. Some extraction techniques is involved in partition between two immiscible liquids, others involve in either continuous extractions or batch extractions. Because of environmental concerns, many common liquidliquid processes have been modified to either utilize benign solvents, or move to more frugal processes such as solid phase extraction. The solvent can be a vapor, supercritical fluid or liquid and the sample can be a gas, liquid or solid.