Solvent Extraction Plants

10,000,000 Per Piece

Cotton Seed Solvent Extraction Plant

Get Price Quote

1 piece (MOQ)

Best Deals from Solvent Extraction Plant

Solvent Extraction Plant

10,000,000 Per Piece

1 Piece (MOQ)

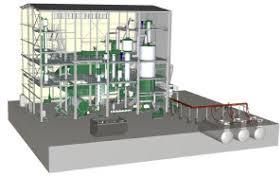

Features: Low maintenance Minimum flow resistance Longer functional life Other Details: Extractor speed is controlled by the frequency controller system with a provision for checking the load on the extractor accurately this provides information well in advance about the extractor band conveyor safety The desolventizer toaster is of a very modern design which is energy efficient with 99.9% desolventizing features by a counter current vapor path in the true sense This system achieves far better color and texture of the Soya meal by our unique design Our low temperature distillation system operates the final oil at a temperature much less than others, thus enhancing the bleachability properties of the oil, with less red units in the oil We provide the latest process instrumentation in the plant to maintain the process parameters Operator friendly plant for ease of operations and delivering the quality and quantity output Minimum quantity of effluent generation Plants for processing a wide variety of oil seeds and oil cakes Robust plant and machinery with bought out items from standard suppliers Unmatched quality performance

Effluent Treatment Plant for Solvent Extraction

475,000 Per piece

1 piece (MOQ)

Reaction Extraction Unit

140,000 Per unit

This is a general purpose batch reaction distillation unit to be operated at atmospheric pressure or vacuum. While heating bath heats and evaporates the contents of the vessel, the stirrer agitates to avoid heat spots. Vapors enter the condenser through reflux divider and get condensed. The condensate is then cooled by a product cooler and collected into a receiver. The unit is complete with a spherical vessel, drain valve, heating bath, thermometer pocket, liquid additional vessel, stirring assembly with drive, coil condenser, reflux divider, product cooler and receiver with drain valve.

Solvent Extraction Unit

Get Price Quote

We are recognized as the leading herbal extract machine manufacturer from India. Used for the extraction of oleoresin and concentrate from various herbs and spices, this oil extraction plant is widely demanded by our customers. In addition to this, this herbal extract machine is also available in varied specifications and can also be customized as per the demands of our customers. Durability, low maintenance and minimal flow resistance are the features of Solvent Extraction Unit provided by us. This can be obtained at the most competent prices. The main attributes of our solvent extraction unit include : Low flow resistance Very durable Require low maintenance Established and time tested engineering No marginal deviations in gravities Ensured complete recovery of product

Nicotine Extraction Plant

550,000 Per piece

1 Piece (MOQ)

Nicotine is a natural product of tobacco, occurring within the leaves of nicotiana tabacum during a range of 0.5 to 7.5% counting on variety. Nicotine is additionally found within the leaves of wild tobacco, in amounts of 2–14%; in Duboisia hopwoodii and in Asclepias syriaca.

Solvent Extraction Plant

Get Price Quote

Liquid extraction, sometimes called solvent extraction, it the separation of a liquid of a liquid solution by contact with another insoluble liquid. The Fully Automatic Solvent Extraction Plant described is for semi-batch operation. The liquid to be extracted is poured into extraction vessel. Solvent is boiled in a reboiler vessel and condensed in an overhead condensed, the condensed liquid in a reflux divider and passing through pipe work to the extraction vessel. The pipe work incorporates valve in order that the solvent can enter the extraction vessel at either the base of the top, depending on the relative density of the solvent and liquid to be extracted. The solvent and the extracted liquid pass back to the reboiler and the process is reputed until the extraction is complete. The extraction vessel is than drained and the solvent evaporated from the reboiler vessel and collected in the extraction vessel enabling the two liquids to be drained from their respective vessel. The Solvent Extraction Plant is available in vessel size upto 500 Ltr. and is suitable for operation under atmosphere pressure and vacuume. Today, we have carved a niche as one of the prime Modular Solvent Extraction Plant Exporters based in India.

Solvent Extraction Plant

Get Price Quote

We provide Solvent Extraction Plant at Big Byte Innovations Pvt Ltd, which is also recognised as liquid harvesting. Solvent extraction is a technique of extracting various components from one liquid phase into another liquid phase. It can also be defined as a method of separating elements from a combination by dissolving them in a solution. Solvent Extraction Plant from Solvent Extraction Plant Exporters employs materials that are chemically distinct and can thermodynamically decompose at higher temperatures. It is appropriate for materials with similar vapour pressures. The product could indeed be easily extracted from the mother solution without the use of any moving parts within the system. The technique is suited for materials that may cause problems due to a minor difference in specific gravity. Our manufactured goods are made from the highest quality raw materials, which guarantees the product's sturdiness. Top-notch designs, better rates, and delivery speed are the three key factors in our customized designs that are the main aspects of our achievement. Our professionals use cutting-edge technology and machines to manufacture these products in accordance with international quality standards and guidelines. Furthermore, they help to reduce the dangers of environmental damage and are thus environmentally friendly. The plants are ergonomically correct, energy-efficient, coherent in output quantity and quality, user-friendly, and produce less affluent

Commercial Solvent Extraction Plant

Get Price Quote

The organization is indulged in offering secured payment procedure including both online and offline methods. To maintain more clarity of the transaction, we offer an invoice as well. We own a well-maintained storage facility that helps us in meeting bulk and urgent requirements of the clients at a time. It is managed and maintained by the storekeepers.

Sunflower Seed Solvent Extraction Plant

Get Price Quote

We are main supplier of this product.

Continuous Solvent Extraction Plant

Get Price Quote

Mechanical method is the combo of high pressure, high temperature, & high moisture, which causes color fixation, oxidation, and hydrolysis. Some seeds like rice bran & soya cannot be handled by the expellers. Continuous solvent extraction plant does not cause any alteration to the property of oil and recovers it with the characteristics as where present in the raw material and can handle all materials.

Continuous Solvent Extraction Plant

Get Price Quote

olvent Extraction Plants process mainly comprises of the following steps: a. Preparation of Oil CakeSeeds suitable for Solvent Extraction Plants to remove oil and produce defatted meal. b. Hexane Solvent Extraction Plants of the material obtained from Step-A by using food grade n-hexane as solvent. The Extractor is a slow moving articulated band conveyor inside a totally enclosed chamber. The band conveyor is lined with perforated sheet, covered with stainless steel wire mesh for easy percolation of Miscella. The Band Conveyor moves on the rail provided inside the solvent extractor. A series of sprays are located above the band conveyor for spraying miscella and solvent on top of the moving material bed of the extractor. During the movement of the bed through the extractor it is washed continuously at various points with miscella of decreasing concentration and finally with a fresh solvent extraction plants in a counter current manner by means of sprays kept in a line over the meal bed. The miscella percolates through the meal bed, pass through bottom and collects in various hoppers kept below the bed which ultimately flows to the miscella holding tank. The extracted meal from the band conveyor falls into the discharge bin conveyed to the desolventising section by vapour seal chain conveyor.

Solvent Extraction Plant

Get Price Quote

We have Solvent Extraction Plant. MUEZ-HEST Solvent Extraction Plants square measure used for extraction of oil from oil bearing seeds and cakes like Rice Bran flavorer, Sunflower, Soyabean, Mustard Cake, Ground nut Cake, Neem Cake, Mahuwa Cake, helianthus Cake and different oil seeds and cake.We square measure specialised within the manufacture of superior quality Solvent Extraction Plant for petroleum refinery trade. Our advanced in-house unit assists within the planning & development of high performance Solvent Extraction Plant at competitive costs.Solvent Extraction plants square measure designed to extract oilthumb(27) directly from helianthus seeds, peanuts, cotton seed, nut, canola, copra, castor and kind of different materials. Solvent extraction consists of 4 main operations, • Extraction of oil from oil bearing seeds cakes. • De- solventising of de-oiled seeds cake. • Distillation, to separate the solvent from the Miscella. • Recover the solvent for apply. Salient Features: • Continuous operation. • Lower Solvent Losses. • Low sediment within the final oil. • Long Extraction time making certain low rock oil. • Simple, rugged style for low maintenance and reliable operator. • simple to move and install.

Sal Plant

30 - 50 Per Piece

Sunflower Cake Based Solvent Extraction Plant

Get Price Quote

1 Set(s) (MOQ)

Solvent Extraction Plant

Get Price Quote

Horizontal Model comprising of articulated band conveyor assembly, which receives the material from the Feed Hopper and transport, it at a very slow predetermined speed from the feed to the discharge end. The conveyor moves over the rails suitably located inside the Extractor and the rides on specially constructed sprocket at either end, adjustable damper for regulation of the height of the bed of material on the chain conveyor, series of Spray breakers for the perfect spray of the solvent on the moving bed, with liberal provision for light sight glasses. Band Conveyor Assembly designed in such a way to act as filter bed for eliminating fines, complete with rotary brushes & mesh cleaning system for effective cleaning of mesh. Salient Features Drive Extractor has single piece Hollow shaft gear box having out put of 0.05 rpm, which is mounted on the extractor main shaft. This is excellence of engineering that avoids the use of Big Gear and pinion arrangement prone to frequent maintenance. Extractor Motor is driven by Variable frequency drive that allows finite adjustment of speed as per processing rates and also allows the data-logging like Run time, stoppage history etc. Construction Extractor has Single piece miscella hoppers having no joint. This reduces the welding and chances of leakage during operations. All body plates and internals are sandblasted and Zink base epoxy primer coated prior to manufacture. This increase life by reducing chances of corrosion and increases life of equipment. Extractor is fabricated in factory, (site fabrication is avoided) and running trial is taken in factory to ensure trouble free running at site. Prefabrication reduces the time for erection and plant will be started quickly. Selection of size is such that the bed height is limited to 1.5m which reduces the chances of miscall channeling. The advantages of low bed height is Rate of mark feeding to DT is consistent, which ensures consistence vapor flow and control on hexane loss. Loading of extractor Bed is low, i.e. weight per square m is low compared to true deep bed extractors which ensures low wear and tear of band conveyor, ensuring long life. Additional two hoppers Extra miscella hopper at discharge end to allow more hexane to drain before it is fed to DT, hence load on DT is low ensuring low steam consumption to evaporate Hexane and low water circulation for condensation as well. Extra miscall hopper at feed end to ensure the settling of miscella before it is transferred to Miscella tank. Major fines are settled in these hoppers, which are then pumped on the top of extractor. The additional miscella spray of this hopper is used to soak the incoming Flakes so that the regular miscella circulation sprays are used effectively.

Soybean Extraction Plants

Get Price Quote

We are the main supplier of this product.

Solvent Extraction Plant

Get Price Quote

The purpose of preparation is to modify the seed into a shape that is suitable for fast and effective extraction by mechanical pressing or by solvent extraction. It is a succession of several of the following processes: seed Dehulling, to increase the protein content of the de-oiled meal, Cracking, to reduce the particle size of the seeds, Cooking, to reduce the viscosity of the oil and adjust the moisture content, Flaking, to rupture the cell structure of the broken seeds, and sometimes Expanding, to enhance extraction parameters.Extraction The seed, having been properly prepared, is separated into a crude oil fraction and a protein meal fraction by solvent extraction. The extractor utilizes a countercurrent, multi-stage washing with commercial hexane solvent to enable a reasonable quantity of solvent to extract a maximum quantity of oil. After washing, the solventladen meal drains by gravity and then discharges to meal desolventising. After washing, the oil/solvent mixture, commonly referred to as “miscella”, discharges to distillation.According to your specific needs, UB Projects provides a complete range of extractors.

Vertical Extractor Plant

Get Price Quote

Solvent Extraction Plant

30,000,000 Per Piece

1 Piece (MOQ)

LJX Food and Tech works towards presenting advanced ways that aid in your extraction. As a trusted solvent Extraction Plant Manufacturer and supplier, we operate with extreme precision and dependability. Utility and Purpose The design of our filtration plant is intended for the extraction of oils, fats, and other important nutrients from raw materials. These include seeds, nuts, and cereals. By using cutting-edge technology and full-fledged construction, we ensure our plants work solidly to achieve high extraction. This also helps with satisfaction of the quality of the product. Applicability They are very efficient for the extraction of products. These include food, medicine and biofuel necessary for chemical, food and bio-fuel production industries respectively. Whether you are looking to fuel biodiesel or extract edible oils, our plants remain consistent in their results. Benefits ● Maximized Extraction: Our plants are designed for better performance. Therefore, the levels of extraction will be enhanced thus, yield and profitability will be maximized. ● Versatility: Our plants are very different from one another, and hence, they give variations in the aspects of extraction. ● Efficiency: Our factories are highly productive with simple operation and automation. They have the efficiency to shed labour and the costs that come with it. ● Customization: We provide a design, which allows you to make the changes and choose every detail. This is to create the plan you need for your business's particular needs and targets. Partner with LJX Food and Tech using cutting-edge solvent extraction facilities. This will add efficiency to your production lines and give you an upper hand in the market. As trusted Solvent Extraction Plant Manufacturers and Solvent Extraction Plant Suppliers, we shall ensure you receive competent and attention-to-detail solutions for your extraction needs.

Solvent Extraction Plant

100,000 Per Piece

Rice Bran Solvent Extraction Plant

Get Price Quote

Continuous solvent extraction plant of rice bran processing capacity 170 MTDay, manufactured by Agrochem Engineers, Tumkur, Karnataka, in the year 2005. Plant consisting preparatory section, main plant, dob section, storage section and utilities like cooling tower, weighbridge and ETP. Plant is in excellent condition. Details of some of major equipment are Preparatory section - Pelletizer 2 nos. 80mtday-each, cooker 200mt, siever 300 mt

Solvent Extraction Plant

400,000 Per Set

1 piece (MOQ)

Solvent Extraction Plant

Get Price Quote

Rice Bran Solvent Extraction Plant

Get Price Quote

Rice bran is the by-product obtained during rice milling operation. It is the golden reddish outer layer obtained after removal of husk and during polishing of rice. Rice bran contains 16 to 22% oil and this oil is recovered by solvent extraction process. Rice bran being floury material, it is essential to pelletize the bran before being put to solvent extraction process. The process of Solvent Extraction involves the injection of hexane into the oil bearing materials resulting in a mix of oil and solvent, called miscella. Hexane from miscella is later evaporated using Distillation unit and resulting in unrefined oil. Hexane so evaporated is condensed and can be recycled.

Solvent Extraction Plant

Get Price Quote

Solvent Extraction Plant that we offer is also known as liquid-liquid extraction. Solvent extraction is a method by which different components are extracted from one liquid phase into liquid phase. It can also be said as a process to separate components from the mixture by dissolving it in a solution. Solvent Extraction Plant makes use of such materials that are different chemically and can thermally decompose at higher temperatures. It is suitable for such materials that have same vapor pressures. The product can be easily recovered from the mother liquor without making use of any moving components inside the system. The method is ideal for those materials that can possibly create problems owing to their marginal difference in the specific gravity. Our Solvent Extraction Plant works upon the super class of solvent extraction theory. Also, we provide organic solvent extraction equipment. Featurers Of Solvent Extraction : Most Widespread Technique Speedy Latest Design Good Output Easy Handling Multipurpose Our manufactured products are made up of finest quality of raw materials due to which it ensures durability in the product nature. There are mainly three factors in our designed products which are the main keys of our success and these are quality designs, competitive price and timely delivery. We Have Cover Following Markets : USA : Montana, Florida, New-Jersey, Alaska-Nevada, New-Mexico, South-Dakota, Texas,etc. Middle East : Yemen, Syria, Arabia, Oman, Israel, Kuwait, Jordan, Saudi, Egypt, Cyprus,etc. Europe : Malta, Austria, Italy, Albania, Finland, Croatia, Andorra, Sweden, Poland, Monaco,etc. Others : Bhutan, Nepal, Pakistan, China, Myanmar, Maldives, Bangladesh,etc Indian Areas : Orissa, Bihar, Rajasthan, West-Bengal, Andhra-Pradesh, Punjab, Assam, Gujarat, Himachal-Pradesh, Karnataka, Mumbai, Haryana, Madhya-Pradesh, Delhi, etc.

Solvent Extraction Plants

125 Per Piece

Industrial Solvent Extraction Plant

Get Price Quote

Solvent Extraction Plant

8,500,000 - 20,000,000 Per Plant