solvent recovery plant

Get Price Quote

1 Set (MOQ)

Recovery of solvents like : Acetone, Toluene, IPA, Ethanol, Methylene Chloride and many other norganic and organic solvents (VOCs)from liquid & gaseous effluents. Processes employed are Distillation (including azeotropic distillation), Extraction (Liquid-liquid & solid-liquid), Absorption, Adsorption, etc. We take up studies for the best possibilities of recovering solvents and other important chemicals from the liquid discharges as well as gaseous exhausts. Solvent recovery from liquid effluents can be from chemical & pharmaceutical manufacturing plants. Solvent & VOC recovery from Solvent Laden Air (SLA) can be from Rotogravure & coating machines used in polyester printing setups. Gasket, electrical part manufacturers, which use organic solvents in their processes. We offer turnkey projects for the above comprising of the following : TECHNOLOGY DEVEOPMENT : Piloting to scale up plant design & engineering BASIC ENGINEERING - Mass and energy balances , Piloting,Process flow diagram (PFD), Preliminary Plant layout , other apparatus and equipment specifications DETAIL ENGINEERING - P&ID , General arrangement drawing , E&I Specifications PROJECT MANAGEMENT - Scheduling, Resource management, Interface Management, Control INSTALLATION & COMMISSIONING – Construction management, Loop Check, Test run, Performance Test & Trouble-shooting. Solvent Recovery Plant from SLA Schematic Drawing

solvent recovery plant

Get Price Quote

Organic solvents are widely used in the industry. As a significance, large amounts of liquid waste with various solvents or other impurities must be disposed of. We can recover and recycle your waste solvents back into product grade material. Our solvent recovery plant offers a unique service for the handling, cleansing, purification and recycling of a wide range of solvents. Potentially harmful substances can be cleaned and purified, reducing the need to manufacture virgin solvents from non-renewable resources. Solvent recovery and recycling is achieved through a distillation process that separates the pure solvent from contaminants. We offers tailor-made systems that reduce both the need of fresh solvents and the amount of contaminated solvents: Continuous or Batch distillation Rectification in vacuum and pressure systems Extraction processes Designing ensures consistency in product output Offering a comprehensive process and application technology know-how.

Best Deals from Solvent Recovery Plants

Multipurpose Solvent Recovery Plant

32,000,000 Per Unit

Solvent recovery is the process of extracting useful materials from waste or by-product solvents generated during the manufacturing process. These chemicals can then be repurposed, reducing the need to produce new solvents, while eliminating a large amount of waste and removing potentially hazardous substances from what’s left.Solvent Recovery offers a wide range of application in Industrial solvents users and manufacturers, Pharmaceutical manufacturers, Electronics industry, Agrochemical industry, Chemical manufacturers & Flavours and fragrances.

solvent recovery plants

Get Price Quote

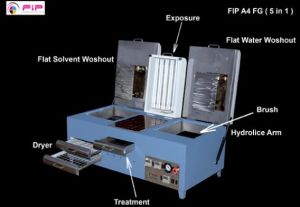

_currently, we are manufacturing flexography photopolymer plate making equipment, including rubber stamp making equipment, letterpress plate making equipment, pad printing photo polymer plate making equipment, label photo polymer plate making equipment , varnish photo polymer plate making equipment, flexo solvent recycling unit, liquid resin stamp making equipment, nylon block making equipment , water wash photo polymer plate making equipment , flexo plate making equipment, flexo photo polymer plate making machine all type of stamp making series , embossing plate making equipment, pharmaceutical batch plate making equipment, woven sack photo polymer plate making equipment, flexo photo polymer die making machine , flexo photo polymer block making machine , photo polymer batch coding machine , flexo stereo photo polymer plate making machine , and all type photo polymer plate making machine series …….for flexographic printing ._.

solvent recovery plants

Get Price Quote

The solvent system used depends upon the behavior of your (crude) product on silica gel. Neat hexane (or a substitute such as petroleum ether or cyclohexane) is often used to wash ‘grease’ (non polar compounds) off the column, whilst neat ethyl acetate (or ether) is often used to elute highly polar compounds.

Chrome Recovery Plant

Get Price Quote

Product Description Mahalaxmi Enterprises has developed Chrome Recovery(Collector) System for the requirements of small and large bath volumes of all Type Chrome Electroplating.This systems recover pure chrome from drag/rinse solutions of chrome bath. Technology: Our Chrome Recovery(Collector) System technology is based on electro-dialysis method using diaphragm for the recover the pure chrome from drag out solution of chrome bath.Chrome Migrate through the diaphragm to the anodic compartment.The recover chromic acid rate of approx 5 gm per Ltr/hours of diaphragm solution.Operations: The Single Diaphragm Chrome Recovery(Collector) System can be installed on one side of the anodic bus bar or at the corner of the drag out/rinse bath, whichever is comfortable for the operator After install the Chrome collector(Recovery) system,fill the diaphragm with the drag out solution and start the DC rectifier,which means unit has been started. The Cr3+present inside the Anodic chamber and as well as in the outer chamber is continuously oxidised to Cr6+ at the respective anodic terminals ,and the Cr6+ being anionicin naturally,gets collected inside the Central anodic Chamber. After some you will see that chrome concentration increased inside the diaphragm,then we will use this pure chrome in main chrome bath, and again diaphragm will fill by drag out solution and start the system continuously. Advantage : This system can be operated continuously with the plating process thereby allowing continuous collected pure chrome and can be directly added to the plating bath. . Decreasing the concentration of hexavalent chrome in the drag out. Decreasing the cost of Chrome bath replenishment and at the same time the cost of ETP chemicals This systems takes very little space, so that the operator does not face any kind of problem. The same DC Rectifier which used for the Chrome plating can be used in parallel for this systems. This systems can be used while the plant is in operation. Maintenance cost equal to almost Zero. Easy to use

solvent recovery plants

Get Price Quote

Ours is a reckoned name in this domain and actively involved in offering quality-centralized product range that is designed and developed using the qualitative raw material. Our product is obtainable in risk-free and industrial grade packing material that make sure the goods are protected from damage and are delivered to buyers in unharmed conditions.

solvent recovery plant

Get Price Quote

Chrome Recovery Plant

250,000 Per Piece

1 Piece(s) (MOQ)

SAVE ENVIRONMENT SAVE LIFE Chrome recovery plant is required by the tannery and leather industry for the recovery purpose.

solvent recovery plants

55,000,000 Per Piece

1 Piece (MOQ)

solvent recovery plant

1,000,000 Per Piece

CentPro is at the forefront when it comes to offering advanced and compact solvent recovery solutions. Our solvent recovery systems are state-of-the-art and are designed to prioritizing our client’s expectations and requirements. Our years of experience, coupled, technological expertise, and acute engineering skills have established Cent Pro as one of the most reputed organizations.At CentPro, one can expect design precision, high-quality engineering equipment, and installation of recovery systems. Our solvent recovery systems offer optimum performance and cost-effective process systems to help our clients achieve their goals and targets.Solvents that are used to clean spray guns and tools are costly. However, due to technological advancements, these solvents are recycled efficiently to cut production costs and prevent high disposal costs. A recycling unit enables restoration and endless re-usage of solvents.Distillation is deployed to restore the fundamental nature of used solvents as it segregates the polluting substances, including paints, oils, greases, resins, and more. Solvent recovery systems manufactured by Cento Pro are of the highest quality and a cost-effective solution to restore the natural properties of solvents.The performance and cost benefits of using our well-designed solvent recovery systems are numerous. The benefits include: High-quality solvents Significant decrease in the costs for reduced waste solvent disposal Storage costs are low Energy costs are low

solvent recovery plants

Get Price Quote

We are the main supplier of this product.

solvent recovery plant

Get Price Quote

solvent recovery plants

Get Price Quote

This is designed for recovery of flexographic photopolymer plate solvent washout chemical and any environmental green chemical with specialties of distilling and cooling, can be connected with in-line processor and any plate washout machine directly. With cold air circulation and drain out of residue for high speed recovery. Super recovering rate in the shortest time, is an ideal and high efficient recovery unit for flexographer.

solvent recovery plants

Get Price Quote

Solvent plays crucial role in modern society. However, complete world’s production of solvent ends up by being destroyed or dispersed in biosphere. Solvents are the source of about 35% of the Volatile Organic Compounds (VOC). Industrial Processes emit solvent vapours in large quantities. These emissions are harmful to environment as well as public health and shall be subject to stringent statutory norms in near future. So, emitted solvent vapour need to be recovered to reduce the harm it is causing to the environment, also it has attractive market value.Our Solvent Recovery systems employ modern distillation technology to separate and recover valuable chemical products from waste mixtures. Using our systems, you can recover and reuse solvents from a wide range of processes – even from complex mixtures with high variability from batch to batch.Generally there are FOUR methods for solvent recovery and they are as follows: Distillation Liquid-liquid extraction Steam stripping Absorption Out of these four processes we only focus on distillation process. Distillation systems are used to separate and recover high purity solvents suitable for reuse. OUR distillation system can provide both batch and continuous process. We are also involved in trading of solvent. We are the preferred choice by customers in the chemical, pharmaceutical, and other specialty industries around the world for recovery, recycle and reuse of solvents. PROCESS DISCRIPTION:Waste solvent which is to be recovered is heated in the kettle/reactor. Heated (contaminated) solvent is then sent to the distillation column where the separation takes place on the basis of difference in boiling point of the two liquids. Vapors so formed are condensed in primary condenser and the remaining uncondensed vapors are condensed in secondary condenser. Condensate (solvent) is collected in receiver tank which packed, sold and reused . Impurities present in the waste solvent settled down because of sedimentation and drained off from the bottom of the reactor.MPL provides atmospheric, vacuum and azeotropic multi-component distillation systems to separate and purify solvent mixtures. The ranges of solvent includes that are distilled are as follows : Low boilers: Acetone Toluene IPA(isopropyl alcohol) MDC Methanol Ethyl acetate High boilers: Sulfolane Phenol

solvent recovery plants

Get Price Quote

volatile organic compounds contained in the emissions of industrial processes. They provide special solutions ranging from the design and engineering to complete turnkey plants for the most common technologies: solvent recovery systems with activated carbon and traditional, catalytic or thermal, recuperative or regenerative oxidizers. Brofind can boast prestigious references in various industries, such as printing (flexographic, rotogravure, roto-offset, etc.), coating and lamination of flexible packaging, adhesive tapes, painting and coating.

solvent recovery plants

Get Price Quote

Kingsley executed the maintenance work of Breather Valves at various production installations of Ahmedabad Asset. We are satisfied by the performance of the contractor.

solvent recovery plants

Get Price Quote

Solvent plays crucial role in modern society. However, complete world’s production of solvent ends up by being destroyed or dispersed in biosphere. Solvents are the source of about 35% of the Volatile Organic Compounds (VOC). Industrial Processes emit solvent vapours in large quantities. These emissions are harmful to environment as well as public health and shall be subject to stringent statutory norms in near future. So, emitted solvent vapour need to be recovered to reduce the harm it is causing to the environment, also it has attractive market value.Our Solvent Recovery systems employ modern distillation technology to separate and recover valuable chemical products from waste mixtures. Using our systems, you can recover and reuse solvents from a wide range of processes – even from complex mixtures with high variability from batch to batch.

solvent recovery plants

Get Price Quote

Non-condensable gases mostly air gets into the system during the processes like extraction and distillation. These gases can cause damage to the system, and thus, have to be vented out. For this, an absorption system is attached through which the vent gases are passed through. In this absorption system, the gases are passed through vegetable oil that completely absorbs the solvent traces from the gases.We add a special feature to pass the outgoing air and vapors from the plant through water as well where the hexane vapors are absorbed and fed back to the extractor. This ensures that no hexane leaves the plant from vent.

solvent recovery plants

Get Price Quote

solvent recovery plants, high speed dispersers, solvent recovery plants