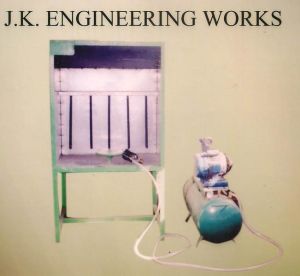

Paint Spray Booth

Get Price Quote

1 Piece (MOQ)

Automatic Water Wash Paint Spray Booth

95,000 Per piece

1 piece (MOQ)

Best Deals from Spray Booths

Mild Steel Paint Spray Booth

300,000 Per Piece

1 Piece (MOQ)

Leather Spray Booth

Get Price Quote

easy to use ergonomics, aesthetics. horizontal and vertical robots , user devices, chemicals with / without water help you making model,pattern and effect that you want

Double Disc Spraying Booth

85,000 - 185,000 Per Piece

1 Piece (MOQ)

Spray Paint Booth

120,000 - 190,000 Per Piece

1 Piece (MOQ)

Paint spray booth (Wet & Dry Type)

200,000 - 600,000 Per ONE

1 Piece (MOQ)

“NSBEC” Manufacturers variety of paint booth system 1. Dry paint spray booth · Cross flow , Side Down Draft , Semi Down Draft , Full Down Draft and Open Face Industrial Booth 2. Wet Type Paint Spray Booth

water curtain type paint spray booth

Get Price Quote

1 Nos (MOQ)

Glazing Spray Booth

Get Price Quote

We are offering premium quality Glazing Spray Booth. Our Glazing Spray Booth finds its usage in numerous applications in agriculture and horticulture. The Glazing Spray Booth facilitates an even and effective spread of chemicals in crop fields. We offer the Glazing Spray Booth with adjustable nozzles for a uniform spread of different quantities. Our customers can get them at competitive price range. Features Adjustable nozzles Flexible Effective spray of chemicals

Paint Spray Booth

Get Price Quote

1 Piece (MOQ)

Bullows is pioneer in manufacturing, supplying & commissioning of Wet Type/Dry Type Paint Booths in Std as well as Customized sizes from Small to large sizes of Paint Booths. We have large customer base for Paint Booth in PAN India location from various Industrial categories where we have supplied Pain Booths for numerous range of Product categories. What is Paint Booth ?An enclosed or semi enclosed area used for spray painting of component may be equipped with a source fresh air to keep the atmosphere dust-free, a waterfall backdrop to trap over spray, and an exhaust system to vent the fumes of the evaporating solvents.Why Paint booth Required ? To provide clean air at the Operators breathing level. To collect overspray & to exhaust clean air. To treat the overspray in such a way that it can later be disposed of outside the building without nuisance or hazard. To reduce fire risk to minimum in spray shop. Working Principal of a Paint Booth:The over sprayed paint is dragged towards the water flowing continuously. The turbulence is created below the screen & sludge is formed. The water and the sludge are separated in the filter at the bottom tank. The clean water is pumped again to the top tank and flows over the screen. The paint is sucked by the blower through the baffles wherein the paint particles are separated. The baffles are very effective in separation and can be removed, cleaned easily. Only clean air with thinner is left to atmosphere. It has more efficiency as compared to the dry booth. The sound level is as per industrial norms. Benefits of a spray booth?A well-designed and maintained spray booth provides important advantages: It separates the spraying operation from other shop activities, making the spraying, as well as the other operations, cleaner and safer. It reduces fire and health hazards by containing the overspray. It provides an area that contains residue, making it easier to keep clean. It also keeps both the operator and the object being sprayed cleaner. In a booth equipped with adequate and approved lighting, it provides better control of the finish quality.

Spray Painting Booth

Get Price Quote

1 Piece (MOQ)

Spray Booth

Get Price Quote

Paint Spray Booth

Get Price Quote

We offer the best quality Paint Spray Booth in water wash type or dry type. Our Paint Spray Booth is designed in such a way that the velocity is obtained throughout the booth chamber. This enables efficient Liquid spray painting. Over spray paint gets washed with the water. Salient Features Environment Control Paint saving Easy Cleaning High Transfer Efficiency High Safety Standards Environment Control Paint saving Operator Friendly

Semi Down Draft Spray Paint Booth

Get Price Quote

water curtain type paint spray booth

Get Price Quote

The spray painting is carried out by operator with the help of spray painting gun (Buyer to arrange spray panting gunj. The paint fume particles are sucked by the partial vacuum created by exhaust fan through a water curtain. The air is cleaned by scrubbing action in turbulent water. The particulate matter remains flowing on water tank Is periodically removed manually. The air discharged Into the atmosphere is clean and thus keeps the environment clean and friendly. Construction & Design The practical expertise enables us to design the Water Curtain Spray Booth with superior performance. The spray booth is modular in construction so that booth can be easily installed, modified or integrated into complete plant. The additional middle suction, deafly provides improved air guidance and better suction of hazardous paint fume particles. The water film thickness on the drain wall can be adjusted individually via throttle valves. Moreover, the unit meets OSHA's safely requirements. Essential Elements of Water Curtain Spray Booth : Exhaust Fan Motor - Paint spray booth is mounted with high efficiency centrifugal exhaust fan and motor to suck the fume and particulate matter in air. Water Pump & Piping - Paint spray booth provided with water pump and suitable piping arrangement for proper circulation of water. Throte Valve - To control water film thickness on the drain wall.

Liquid Spray Painting

Get Price Quote

Liquid paint can be applied in many different ways determined by: the product, the volume, the quality requirements and other factors. Application method: handheld spray guns, high volume low pressure (HVLP) guns, automatic guns, automatic rotary bells or disk. >> Spray equipment: non-electrostatic or electrostatic. >> Typical paint is used for such wet on wet process is epoxy or polyurethane. Paint is normally baked. Painting components with corners & crevices >> Spray cannot reach each & every area. >> In addition, if the component needs high corrosion resistance, then electrophoretic technology will be more appropriate for depositing the primer paint and is followed by spray with top coat of paint. >> Typical components requiring this technology are auto components. Painting large components >> These are shot blasted, can be given a zinc phosphatelayer followed by primer coat of paint which is either applied through manual spray or electrostaticspray. >> This is followed by spray top coat (normally polyurethane acrylic) and is forced to dryat 70-80°C temperature. >> Also for plastic parts, spray painting is used.

Spray Booth

600,000 Per unit

1 unit (MOQ)

Leather Spray Booth

200,000 Per Pack

1 Piece (MOQ)

Spray Booth

Get Price Quote

We are offering spray booth. autocoat engineering have been manufacturing superior quality spray booth among other valuable products. We have wide experience of manufacturing paint booth with different material handling and different product size , and different production volume. autocoat engineering is one of the most renowned company when it comes to spray booth manufacturers in india & spray booth suppliers in india autocoat engineering painting booth is designed (most critical is spray booth design), manufactured , assembled & tested for performance before dispatch and commissioned at site to achieve customer 100% satisfaction. Most of our customers are corporate companies with iso certification and with stringent quality requirements.

dry paint spray booth

Get Price Quote

For ensuring quality products at buyer's end, we check each and every product at diverse stages including production, packaging and delivery. You can opt to make payment by LOC, COD, Cash / Bank transfer, etc. according to the suitability of patrons. We are familiar with all and we make sure the transactions are secure.Features : Economical Dynamically balanced centrifugal fan Centrifugal fan capacity ensure removal of paint over spray and comfort to operator Bolted panel construction for easy assembly Flame and explosion proof motor (Optional) Good Illumination by fluorescent lamps Applications : Dry paint booth's are typically used for low volume production.Some typical examples of its use are shown below - R & D facility Automotive ancillary Units Pumps, motors, valves, gear boxes and generator manufacturing industries Electrical and Electronic device industries Home appliance industries Toy manufacturing industries