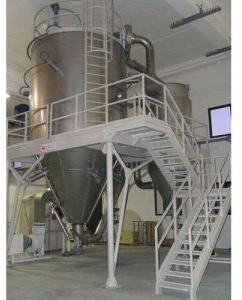

spray drying plant

100,000 Per Piece

1 Piece (MOQ)

Industrial Spray Dryer

Get Price Quote

Spray Dryer technology is widely used in the industry for converting liquid solutions/ suspensions/ slurry /emulsions to powder, granules or agglomerates. The advantages of spray drying are consistent product quality, with better control on product parameters like product moisture, bulk density, particle size, dispersion, flow ability etc. AVM offers Customized Spray Drying Systems with variety of Configurations. Air Flow Pattern Configurations : Co- current. Counter-current. Mixed flow. Combination of Systems Configurations : Two Stage Spray Dryer : Spray dryer followed by fluid bed dryer for drying products which require longer residence time & product conditioning post drying. Three Stage Spray Dryer : Spray dryer with Internal fluid bed followed by external fluid bed dryer for producing dust free agglomerates. Liquid Atomizer Configurations : Single Fluid Nozzle Atomizers : The liquid feed is atomized into spray droplets by using pressure energy. Two Fluid Nozzle Atomizers : The liquid feed is atomized into spray droplets by using energy of secondary fluid like Compressed Air, Nitrogen etc. Rotary Disc Atomizers / Rotary Atomizers : In Rotary disc Atomizers, the kinetic energy of wheel is used for atomization. Air Heating System Configurations : Direct Fired / Indirect Fired Air Heaters: using Liquid / Gaseous Fuels. Direct / Indirect Fired Air Heaters: using Solid Fuels, Agro Waste, Saw Dust, Rice Husk, Coal, Briquette etc. Indirect Air Heaters: Using Steam / Hot Oil / Thermic Fluid. Electric Air Heaters: using electricity. Product / Fines Recovery System Configurations : Cyclone Separators – Mono, Twin, Quadruple, Multi etc. Bag Filters – Reverse Pulsejet, Mechanical shaking etc. Wet Scrubbers – Direct Contact Ventury, Adjustable Ventury, Packed scrubbers etc. Optional Features Configurations : Rotating air brooms with dehumidified air. Roof cooling. Rotary atomizer Cooling. Nozzle Lance Cooling. Online Dosing & Blending system. Product Cooling & conveying system. Online gas induction system in feed liquid. Feed Preparation system. Closed Loop Systems / Self Inertized Systems with inert gas as process drying media. Solvent Recovery Systems. Cleaning in Place Systems. Heat Recovery Systems. CGMP Construction. Safety accessories like Explosion vents with pressure shock resistant design for equipments, explosion de-coupling, Mechanical flame diverter, Vacuum breaker, Fire fighting system. Computerized control system through PLC / DCS & SCADA.

Best Deals from Spray Drying Plant

Chicory Spray Drying Pump

Get Price Quote

1 Piece (MOQ)

Chicory Spray Drying Pump is used for Spray drying Chickory at high pressures. These Screw Pumps are widely appreciated for their robust design, energy efficiency and durability. We manufacture these Screw Pumps using superior quality raw materials that are procured from the trusted vendors in the market. This Screw Pump can be customized according to the specifications of the customers. We offer these at affordable prices in the market. MATERIAL OF CONSTRUCTION Pump Housing, End Piece : SS304 / SS316. Rotor : SS304 / SS316. Shaft : SS304 / SS316. Sleeve,Pins, Connecting Rod : SS304 / SS316. Rubber Stator : FOOD GRADE RUBBER Base plate : M.S. Shaft Sealing : MECHANICAL SEAL / TEFLON PACKINGS

Industrial Spray Dryer

Get Price Quote

Atomizer Spray Dryer

Get Price Quote

1 Piece (MOQ)

spray drying systems

Get Price Quote

spray drying system

1,000,000 - 7,000,000 Per Piece

1 Piece (MOQ)

Spray Dryer Milk & Herbal Powder Spray Dryer Plant

Get Price Quote

Spray Drying Detergent Plant

25,000,000 Per Piece

1 Piece (MOQ)

Industrial Spray Dryer

Get Price Quote

Spray drying is a process where dry powder is produced from liquidslurry by constantly drying it with hot airgas. Benefits of spray drying 1. Consistency in product particle size. 2. Short residence time required, which makes the drying process fast and cost effective. 3. Homogeneous production we are into spray drying job works for over a decade now, and have gained expertise in the following products: 1. Surface active agents 2. Sodiummetal salts of organic products 3. Potassium salts 4. Fertilizers (micronutrients) 5. Low temperature enzymes 6. Food products 7. Pharmaceuticals

spray drying plant

800,000 Per Piece

1 Piece (MOQ)

spray drying plant

500,000 Per

spray drying systems

Get Price Quote

A DECADE OF EXPERIENCE SAKAV, established in 1985, has developed and supplied a wide range of SPRAY DRYING SYSTEMS to the Chemicals, Dyestuffs, Ceramics, Food, Polymers and Pharmaceutical Industries in India and Abroad. With its vast specializes experience, resources and innovative technical know-how, SAKAV offers the most appropriate systems for all Spray Drying requirements designed and delivered by Sakav incorporate practically every conceivable combination of system components to meet a variety of product requirements. THE SPRAY DRYING OPTION A spray drying system employs a single process to convert a solution/slurry into a powder. The liquid is atomized, in a specially designed Drying Chamber, into a stream of hot air to evaporate the solvent. The dry powder is then separated from the air stream. Sakav custom designs a system to suit the product quality, feed conditions, heating source available and the local environment norms. The chamber geometry, spray pattern and the air flow distribution have a decisive influence on the product characteristics. Each system is a harmonious combination of individual process sections of Air Heating, Feeding, Atomization, Powder Collection and Dust Separation. The wide variation of combinations handled by SAKAV are given in the table below - ROTARY ATOMISER SAKAV with its in-house design capabilities ha built and supplied a range of Rotary Disc Atomizer. These are belt driven units with standard electrical motors. A number of models are available with wheel diameters of 100mm to 350mm and are suitable for capacities from 5 lit/hr to 10,000 lit/hr Various configurations such as orifice, pin, vane with stainless steel and ceramic wear parts are available. A variety of lubrication systems starting from continuous drip to fully automatic forced lubrication systems can be provided. Speed variations are achieved by changed pulleys or variable frequency drivers. TEST FACILITY Fully equipped dedicated Pilot Spray Dryers are available for conducting trials on customers samples and simulation of ideal drying parameters for individual products. Assessment of their physical properties such as moisture content, approximate particle size distribution and bulk density. Testing is an on-going process and SAKAV has, over the years, built-up a large data base for a wide variety of products. THE CHAMBER OPTIONS The chamber configuration plays an important part in meeting the end product requirements. As is apparent from the table there is an endless number of possible combination. Some of these have been depicted below. FLAT ROOF This is the most widely used configuration of spray chamber with flat roof construction. Co-current swirling air flow pattern is used in conjunction with centrifugal atomization. Generally used for producing a uniform fine powder. Dry powder can be collected partly under the chamber and the fines from the cyclone. Alternatively a single point collection under the cyclone can be provided. Can be adapted for nozzle atomization with an add-on air distributor. TALL FORM - BUSTLE The standard Tall Form Bustle construction with co-current linearized air flow pattern is sued with pressure nozzle atomization systems. The dry product is usually coarser than centrifugal disc atomized product. The bustle construction enables separation of coarse fraction below the chamber and the fines can be collected from the cyclone. This configuration is deal where fines recycle is used for product agglomeration. TWO STAGE A configuration consisting of Tall Form Spray Chamber with a second stage Fluid Bed Dryer is used for special applications. This configuration is used for products requiring longer drying times which cannot be provided in Spray Chamber. This occurs when a coarse product has to be dried to a very low moisture content or when the product to be dried is hygroscopic in nature

Stainless Stainless Industrial Spray Dryer

Get Price Quote

Industrial Spray Dryer

Get Price Quote

Spray Dryer method OR process is the most economic method OR process of evaporation to convert liquid feed OR slurry having specific percentage of solids to solid powder particles. Still powder is one of the most cost effective in both storage & transportation of finished goods.We provide turnkey projects of Spray Dryer for MCCP, Microcrystalline Cellulose Powder, Zinc Sulphate Powder, Sulphur WDG Powder, Herbal Extract.Our Spray Dryer Technology has developed a wide range of Spray Dryer Chambers to suit the widest range of material Our Scope of plant ranges from 5 kghr laboratory models to full scale high volume production models in excess of 5000kghr and can meet any required industrial manufacturing specification.

Industrial Spray Dryer

50,000 - 100,000 Per Units

spray drying plants

500,000 Per unit

1 unit (MOQ)

Industrial Spray Dryer

Get Price Quote

You want to benefit from an ingenious technology of spray drying for your demanding product development process. We offer the market leading solution with the most possibilities in applications to reduce development time Spray drying, spray chilling, and microencapsulation with one product. Processing of organic solvent based samples in combination with the Inert Loop B-295 Processing of organic solvents and water mixtures based samples in combination with the Inert Loop B-295 and the Dehumidifier B-296

Industrial Spray Dryer

Get Price Quote

We are offering industrial spray dryer. Special features 1.dryer has steep cone bottom for free flow powder. 2.special reinforcement structural allow drying chamber to expand hence no dent is formed during expansion & contraction. Multi cyclone design gives better recovery of product. 3.single point collection to minimize dusting automatic temperature and feed rate controls. 4.plants are designed in closed cycle version for drying feed containing organic solvents. 5.aseptic design offered for pharmaceutical application.

spray drying plants

Get Price Quote