DC Spring Loaded Brake

2,000 - 25,000 Per Piece

We have in our store a wide array of Electro Magnetic Disc Brake. Manufactured using high-grade raw material procured from the authentic vendors of the market, these products find their applications in industrial vehicles and heavy vehicles. Further, these products are designed and developed strictly in accordance to international quality standards. With a high class insulation coil, these products have good quality liner plate.

Spring Applied Brakes

Get Price Quote

1 Piece(s) (MOQ)

We are offering spring applied brakes. The braking of high flywheel inertia is possible by the brakes with large heat capacity and high heat dissipation. The electromagnetic fail safe brakes are designed to interrupt the torque transmission in the event of power failure. The braking torque is applied by spring force when power supply to the coil is interrupted. These brakes meet the requirements in machine tools,winches,conveyors etc, where for safety reasons, instant and reliable braking is required. The braking torque is produced by multiple coil springs acting on the plates and released by the magnet coil. Torque range 7.5 nm --- 350 nm voltage 24 v.d.c

Best Deals from Spring Brakes

Hoist Spring Loaded Fail Safe DAT Brake

8,000 Per Piece

10 Piece (MOQ)

Spring Set Brake

Get Price Quote

Wichita A Market Leader for Pneumatic and Hydraulic Clutch & Brake ,Tension Control System Standard Torque Range from 0.25 Nm TO 2,000,000 Nm and Speed Range from 120 Rev/Min To 5250 Rev/Min Application Scope : - For Smooth power take ups High Frequency Start and Stop operation High Torque within compact design Combined unit for cyclic application Continuous slipping duties Safety duty application Tension control Market Served :- Metal forming machinery Mining Marine Forestry Paper & foil tensioning Dynamometry testing Petro-chemical & Off Shore equipment Heavy Industrial Machinery.

Spring Holding Brake

Get Price Quote

Spring Loaded DC Fail Safe Brakes

Get Price Quote

Type 14.448 (Spring Loaded DC Fail Safe Brakes) :: ::Salient Features :: ::>Adjustable Brake Torque ::>Optimized Torque Steps ::>Simple Wear Adjustment ::>High OPerating Frequency & Reliability ::>Low Power Requirement ::>Low Rotor Inertia ::>Two Friction Surfaces ::>All Metal Parts Protected From Rust ::>Coil With Class 'F' Insulation ::>Residual -Free ::>Fast Switching Times ::>Simple Construction ::>Stationary Field (No Slip Rings) ::>Consistent Operating Characteristics ::>Raw Materials To DIN Standards ::>No Restrictions On Mounting Positions ::>Registered Designs 156544 ::

Spring Applied Brakes

Get Price Quote

Hydraulically Released Spring Applied BrakesThere is a variety of possibilities to use hydraulically released spring-applied multi-disc brakes in the stationary and mobile sector, also combined with hydraulic motors. The brakes can be integrated in the oil circuit of the motor. When starting the hydraulic motors, the brakes release with oil pressures of 15 to 38 bar. Thereafter the full system pressure up to 320 bar can be connected. The brakes can be used in wet and dry operation. With failure of the oil pump, an emergency release is possible. Application Examples Series KMB. e.g. general machine manufacture,travelling and conveying gears, every kind of hydraulic drives, winch, lifting, turning and slewing gears, building machines, shipboard and mobile cranes.

electromagnetic spring brake

Get Price Quote

Spring Applied Brakes

Get Price Quote

In a Spring Applied Brake, when the current is given to the statorbrake coil the armature plate is pulled towards the stator against the applied spring force which releases the rotor. And when the current supplied is turned off, the strong compression springs push the armature back to its position which in turn clamps the rotor and provides the specified braking torque

spring loaded brake

Get Price Quote

Spring Loaded Failsafe Disc Brakes

2,100 Per unit

Spring Actuated Brakes

Get Price Quote

The CMW model is an all-in-one unit integrating a reducer, motor, clutch and brake that drives the input of CBW model by a motor through bearing. Due to its integrated configuration, the mounting space can be saved. The trouble of centering or processing can also be saved. Setting can be completed simply by connecting the output shaft with the load side.

spring loaded fail safe brake

Get Price Quote

spring loaded fail safe brake

Get Price Quote

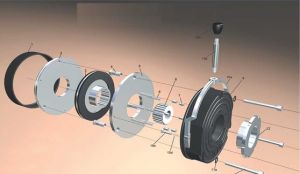

salient features compact robust unit simple wear adjustment high operating frequency with manual release provision. coil with class 'f' insulation all metal parts are rust protected. two friction surfaces low power requirement working of efsb the braking torque in excel spring loaded fail safe brake is generated by several compression springs (6) whose axial spring force presses the armature plate (5)against the rotor (3)which in turn is pushed against the mounting flange(2). On applying direct current power supply to the coil (9) magnetic field is produced, which pulls the armature plate over the airgap towards the "stator" against the spring force and the rotor is free to rotate and hence brake is released. the brakes are provided with manual hand release assembly and can be used for releasing the brake in case of power failure. description 1. Dust protective ring 2. Flange 3. Rotor 4. Tubular bush 5. Armature plate 6. Compression spring 7. Compression parts 8. Hub 9. Outer pole 10. A- handle b- h.r. Lever c- knob d- h.r. Spring e- h.r. Bolt 11. A- spring washer b- mounting bolt 12. Torque adjustment nut size selection and ordering information approximate necessary torque or size of a unit for applications involving low inertia & low operating frequency is determined as ; torque = [ 9550 x (k.w. / speed)] x safety factor [k] safety factor [k] to ensure necessary transmission safety also under extreme operating conditions adequate safety factor must be considered the value of which depends on operating conditions namely, the type of load, prime mover etc. Typically [k]for electric drive low masses equal loading & non-intermittent operation [2.0] low masses light shock load & intermittent operation [2.5] medium masses, light shock load & intermittent operation [3.0] large masses, light shock load & intermittent operation [3.0] non-overhauling loads [2-3] overhauling loads [3-4] diesel engine drive [4-5] compressor driven [5-6] however, we recommend you to perform detailed calculations for which please consult us. life of friction material the life of the friction liner depends on a number of factors namely, the inertia to be retarded or stopped, the relative speed, the operating frequency, the temperatures at the friction surfaces etc. These brakes must run dry. Oil, grease, foreign materials & other lubricants affect life and characteristics of friction material. electrical connections the brakes are operated with dc. Connection from three phase or ac mains network can be made via a transformer rectifier, bridge rectifier or half wave rectifier. To restrict the high inductive voltage / back emf a suitable supressor and capacitor network is provided across the connector coil as shown in fig.

spring brakes

4,709 Per Piece

1 Piece (MOQ)

spring loaded fail safe brake

Get Price Quote

Non Fail Safe Brakes

Get Price Quote

5 Piece(s) (MOQ)

We are offering non fail safe brakes. Normally-off type operates on power. When power is given to brake coil, armature plate is attracted towards the linear of the brake stator which clamps the rotating component stop to once. On switching off the power, the prestressed spring pulls the armature plate backs to its original position and brake is positively released with no residual torque.

Spring Applied Brake

Get Price Quote

Item Code : Spring Applied Fail Safe Brake Type FSB Magpower Linksys are manufacturers of Clutches and Brakes which are intended for Start-Stop applications. They come in various types to meet different requirements. Type FSB Magpower Spring Applied Brakes Type FSB are typical fail safe brakes. Its braking torque is produced by spring pressure and the brake is released electromagnetically. When there is no current flowing through the brake coil, the fail safe operation of the brake is derived from the braking torque generated by the spring pressure. When current flows through the brake coil, the spring pressure is neutralised by the developed electromagnetic force, which enables the brake to be released. They are suitable for dry applications only. These brakes are thus safety brakes coming into, action in the event of a power failure, arresting motion instantaneously. Features Magpower Spring Applied Fail Safe Brakes incorporate a telescopic tubular wear adjustment system which facilitates easy maintenance. Alternatively, these brakes can also be provided with spacers, wherein the airgap is preset and can be initially mounted without any adjustment.Individual Spring pressure adjustment permits precise setting of braking moment.A low level of wear owing to the use of an abrasion resistant friction material and a large friction area.Manual release is provided as an additional features which enables the brake to be released mechanically, in case of power failure.The brake have short switching time and operate in milliseconds.Seals are provided to prevent the ingress of foreign matter, thus ensuring a long life and smooth functioning of the brake. Ordering Information Type, Size, D.C. Voltage, Bore Diameter, Design. Example of order Type : FSB, Size : 08, 24 VDC, Bore Diameter – 11mm, Design 104 For selecting the correct size of the brake, the factors to be considered are Max. reqd. braking torque.Freq. Of operations.Max. thermal load. The reqd. braking torque can be calculated using the formula M = (9550 pn). s (Nm)M = reqd. Static torque (Nm)p = Power rating of prime mover in KWn = Rev Mins = Service factor depending on application (1.5 to 4.0)For switching details and complicated calculations, please get in touch with us. Magpower Spring Applied Fail Safe Brakes require D.C. Supply. Product Line Electromagnetic Single Face Brakes (Normally Off) – Type EBElectromagnetic Single Face Clutch – Type ECElectromagnetic Single Face Bearing Mounted Clutch – Type BMCClutch – Brake Combination Encased – Type CBEClutch – Brake Combination Open – Type CBOSingle Shaft Double Clutch Unit – Type SSDCSingle Shaft Clutch Brake Unit – Type SSCBHollow Shaft Clutch Brake Unit – Type HSCBEA.C. Fail Safe Brake – Type AFS Click Here to View Dimensions

Electromagnetic Release Spring Holding Brakes

Get Price Quote

We are offering electromagnetic release spring holding brakes (d. C. Voltage). features: • low cost brake designed for holding application • emergency braking capability • iec or nema motor mounting ready rated brake torque range 0. 1 n-m to 1500 n-m outer diameter range : 37 mm to 365 mm

industrial spring applied brakes

Get Price Quote

industrial spring applied brakes, Magnetic Clutch, Dc magnetic brake