Demountable Mechanical Strain Gauge

20 - 25 Per Piece

1 Bng (MOQ)

Demounting Strain Gauge

Get Price Quote

1 Piece (MOQ)

Best Deals from Strain Gauge

Demountable Mechanical Strain Gauge

Get Price Quote

1 Piece (MOQ)

Strain gauge All size (WELLTEK)

32 - 300 Per pieces

5 Piece (MOQ)

PAXS0000

18,500 Per Piece

1 Piece(s) (MOQ)

PAX STRAIN GAGE

Strain Gauge

Get Price Quote

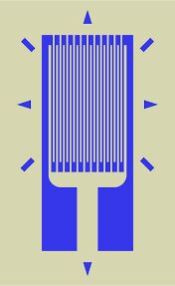

Strain gauges used to apply electrical measurement techniques to the measurement of mechanical quantities. As their name indicates, they are used for the measurement of strain. As a technical term, “strain” is comprised of tensile and compressive strain, distinguished by a positive or negative sign. Thus, strain gauges can be used to detect expansion as well as contraction. The strain of a body is always caused by an external influence or an internal effect. Strain can be caused by forces, pressures, moments, heat, structural changes of the material and the like. If certain conditions are fulfilled, the amount or the value of the influencing quantity can be derived from the measured strain value. In experimental stress analysis, this feature is widely exploited. Experimental stress analysis uses the strain values measured on the surface of a specimen or structural part to determine the stress in the material and also to predict its safety and endurance. Special transducers can be designed for the measurement of forces or other derived quantities, e.g., moments, pressures, accelerations, displacements, vibrations and others. The transducer generally contains a pressure-sensitive diaphragm with strain gauges bonded to it. Prime strain gauge selection considerations • gauge length • number of gauges in gauge pattern • arrangement of gauges in gauge pattern • grid resistance • strain-sensitive alloy • carrier material • gauge width

Vibrating Wire Strain Gauges

Get Price Quote

50 Pieces (MOQ)

Innovative series IG1100/1200 strain gauges have a unique integral magnet design which incorporates a miniature magnet coil assembly positioned inside a stainless steel tube of diameter 15mm. The same tube has a high tensile strength, heat-treated and tempered steel wire stretched between two end blocks. The wire is sealed in the tube by means of a set of double O-rings. This feature, when compared to conventional externally mounted magnet design has the following advantages: Robust anstallation and minimum protection needed after installation. Externally mounted magnet assembly on the other hand is prone to corrosion as it is made in two halves, which are externally clamped on to the tube. This does not ensure proper sealing at the joint. Thus water can seep and with time cause corrosion on the magnet, resulting in failure. Embedment type strain gauges are provided with built in stainless steel flanges while the groutable and arc weldable type have the same design. By the use of appropriate type of mounting blocks, the same strain gauge can be arc welded on to the steel structures such as tunnel linings and supports or grouted or epoxy bonded on the surface of concrete structures. To take care of space limitation, for vertical measurement of strain across thin concrete lining, embedment strain gauges with 55mm gauge length are used. For eg. on pavements.Provision of gas discharge tube protects the sensor against surge and lightning. Accessories: 5 position rosette for mounting strain gauge at different angles and in different planes. No-stress container to evaluate strain produced due to factors other than load. Brackets for arc welding on structures or grouting. 6 position junction box to terminate strain gauges installed on Rosette.

Foil Strain Gauge

Get Price Quote

Sensor Strain Gauge

Get Price Quote

As a result of an extensive research, we have successfully come forth with the best quality Sensor Strain Gauge. Manufactured from the quality material and advanced technology, these machines work by indicating deformation or strain of an object with the use of the inbuilt sensor. Additionally, these devices also have application-specific designs, long operational life, and high efficient performance. Extensively employed by the related industries, these machines are available at cost-effective prices from us.

Strain Gauges

Get Price Quote

Strain measurement with the help of resistance wire strain gauges weights, digit digital strain indicator with amplifier for strain gauge bridge circuit. Accessories include a cantilever beam mounted with strain gauges, weights.for the bridge circuit.

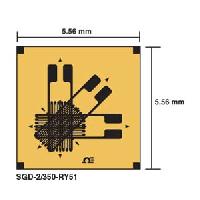

Strain Gauges

3,800 Per Piece

1 Set(s) (MOQ)

Systel Series 1000 model Strain Gage is designed to measure the changes in strain in and on structural members associated with many types of structure. Concrete Dams Buildings over tunnelling works Deep Excavations Retaining Walls Bridges Pile caps Suitable for portable readout equipment or automatic data acquisition.

Strain Gauge

200 - 250 Per Box

Specifications: Strain Gauges are designed in various configurations to suit varied industrial applications. These Strain Gauges are either foil type or semi-conductor type. These Strain Gauges are very suitable for single, dual and multi axial Strain Gauges measurements.

Strain Gauge

Get Price Quote

PRODUCT DETAILS Strain generated on hanging slotted weights on the extreme end of the metallic strip can be observed by using this instrument on interfacing it with instrumentation amplifier. A foil strain gauge is bonded on a spring steel strip mounted on an Aluminium panel.

Demountable Mechanical Strain Gauge

Get Price Quote

This portable gauge is designed for a gauge length of 20c.m of the reference pins. The deformation isindicated by a 0.002 x 10mm dial gauge attached to the instruments

Strain Gauges

Get Price Quote

We are offering strain gauges.

Demountable Mechanical Strain Gauge

Get Price Quote

Resistance Strain Gauge

12,500 Per Piece

1 Piece (MOQ)

Electrical Resistance Strain Gauge

Get Price Quote

Electrical Resistance Strain Gauge Features Low cost effective teaching Bench mounted Self contained Wheatstone bridge and temperature compensation dummy gauge included Introduction to strain gauges Bending and Torsion included Optional extras for Tension and Compression Three year warranty Range of Experiments To show the application of strain gauges in the measurement of stress, due to bending and torsion To demonstrate the use of a Wheatstone Bridge in measuring change of resistance. With the optional extras to show other methods of temperature compensation in conjunction with tension and compression specimens. Description The apparatus has been designed to illustrate the basic features of electrical resistance strain gauges and their application to measurement of strain and the derivation of stress levels, in bending, torsion, tension and compression. An alloy cantilever has a single gauge bonded onto its surface, and an identical gauge is fixed to an unstressed piece of the same material for temperature compensation. The two gauges form part of a Wheatstone Bridge which has an apex or balancing potentiometer, and whose meter is calibrated directly in microstrains. The cantilever is loaded by weights hung from its free end, a weight hanger is included. To extend the scope of the apparatus the cantilever can be replaced by a torsion bar having two gauges bonded orthogonally at 45º For a complete study of strain gauging two optional extra accessories demonstrate averaging techniques for tension and compression specimens. This equipment is part of a range designed to both demonstrate and experimentally confirm basic engineering principles. Great care has been given to each item so as to provide wide experimental scope without unduly complicating or compromising the design. Each piece of apparatus is self-contained and compact. Setting up time is minimal, and all measurements are made with the simplest possible instrumentation, so that the student involvement is purely with the engineering principles being taught. A complete instruction manual is provided describing the apparatus, its application, experimental procedure and typical test results.

Strain Gauges

Get Price Quote

A strain gauge is a sensor that is used to measure the tension or compression within a part. While there are several methods of measuring strain, the most common is with a strain gauge, a device whose electrical resistance varies in proportion to the amount of strain on the device.

Demountable Mechanical Strain Gauge

Get Price Quote

It is used for finding out the linear deformation caused on two reference points fixed on a loading member. This portable gauge is designed for a gauge length of 20cm. of the reference pins. The deformation is indicated by a 0.002 x 10mm dial gauge attached to the instrument. Complete with two standard bars for 20cm gauge length supplied in a wooden case.Accessories: Reference pins in packet of 10 Nos.