Liquid Hand Wash Filling Machine

150,000 Per piece

1 piece (MOQ)

Automatic Goli Soda Filling Machine

30,500 Per Piece

1 Piece (MOQ)

Best Deals from Stuffing Machines

Automatic Servo Base Liquid Filling Machine

350,000 - 1,150,000 Per Piece

1 Piece (MOQ)

The PLC Based Filling Machine is compact and highly efficient machine with elegant look. This multi functional multi featured machine meets the GMP requirements of filling for glass, plastic or Aluminum bottles. The flow of liquid is measured and converted in to electronic signals being controlled by micro computer base circuitry. Minimum adjustment required to set different capacities of containers. The entire range can be set on the same machine without any change parts with help of servo system. Application Paint Industry Agriculture Food Industry Any Semi Solid Material Chemical Industry Features No Bottle No Filling System. All Contact Parts made of S.S.316/S.S.304 2 Filling Stations, space saving design. Easy to clean PLC servo base controlling system Pneumatically controlled nozzles, with ‘No Container No Fill’ arrangement. Drip free nozzle arrangement. Reciprocating filling nozzle with self-centering device. Pneumatically operated bottle stopper.

Bulk Powder Weighmetric Filling Machine

Get Price Quote

1 Piece (MOQ)

Digital Control Particle Weighing Filling Machine

16,000 Per Piece

1 Piece (MOQ)

Semi Automatic Syringe Filling Machine

Get Price Quote

Harnessing our experience in the industry, we take the responsibility to deliver utmost quality to the customers. As a Manufacturer, Exporter & Supplier, we offer a range of Semi Automatic Syringe Filling Machine. This range includes different specifications and customizations. Our team of expert professionals keeps quality on the top of our priority list. Such quality is offered at affordable rates. Lay your hands on our machine for economical rates.

Semi Automatic Cup Filling Machine

175,000 Per Piece

1 Piece (MOQ)

Manual Paste Filler

20,500 Per Piece

Semi-Automatic Rinsing, Filling and Capping Machine

Get Price Quote

1 Unit (MOQ)

Semi-Automatic Rinsing, Filling and Capping Machine The Semi-Automatic Rinsing, Filling and Capping Machine consist of a main structure, air conveyor, bottle rinsing unit, bottle filling unit, bottle capping unit, cap bowl with a transfer system, star plate, product transmission belt with an adjustable guide, Safety acrylic cover, AC drive, the motor with gearbox, electrical panel, PLC & HMI. Key Features The machine is manufactured or developed accordance with GMP standards. Structure frame of MS cladded platform and housings of SS 304. Rinse Fill & Seal cycle, fully Trio-block for total filling hygiene. The whole process is semi-automatic. Bottle in-feed using high pressure air conveyor. Air Blow Conveyor on the in-feed. Rotary neck holding. Slat chain Conveyor on the out-feed with the AC Drive and Inspection Table with lighting system & white background. No Bottle – No Rinse – No Fill – No Cap. Unique Pick & Place type Capping. Drive is based on Geneva mechanism hence low on maintenance. Speed Control by AC Drive. Vibrator bowl for feeding cap to the chute with semi-automatic operation. Speed indicator on main panel. Can handle all bottle size ranging from 250 to 2000 ml. Capping done by “Torque Adjustable” magnetic capping heads using two-stage Pick & Place system. Stainless Steel enclosure provided for complete hygienic bottling. Easy openable nozzles for easy cleaning. Can handle bottles blown from low grammage Pre-forms without distortion. Can be linked directly to Semi-Automatic Blow Molding Machine for online Blow- Rinse-Fill-Seal. Compatible with Online Shrink Tunnel, Labeling Machine, or Ink Jet Printer.

Liquid Filling Machine

Get Price Quote

We are listed at the apex in the list of the renowned Liquid Filling Machine Manufacturers and Exporters in India. The use of optimum quality materials in the manufacturing of the Liquid Filling Machines ensures their long functional life. Attributes : Unmatched quality Unsurpassable performance High durability Great tensile strength Resistivity to adverse conditions Easy operation High productivity Low maintenance required Features : High-resolution volumetric piston type Filling Built in electrical panel With/without clutch-brake Electronic counter Material of construction Stainless Steel Mild Steel Applications : Ground Coffee Flours Milk Powder Pharmaceutical Powder Chemical Powder Talcum Powder Pesticide Powder Ground Spices

Semi Automatic Single Head Piston Beverage Filling Machine

85,000 Per Piece

1 Piece (MOQ)

Manual Paste Filling Machine

20,000 Per Piece

1 Piece (MOQ)

Linear Honey Bottle Filling Machine

1,200,000 Per Piece

1 Piece (MOQ)

Fully Automatic Liquid Filling Machine

250,000 Per Piece

1 Piece (MOQ)

60 BM Water Bottle Filling Machine

1,400,000 Per Piece

1 Piece (MOQ)

Mehndi Cone Filling Machine

34,000 - 42,000 Per Piece

1 Piece (MOQ)

PET Bottle Filling Machine

1,500,000 - 10,000,000 Per piece

1 Piece (MOQ)

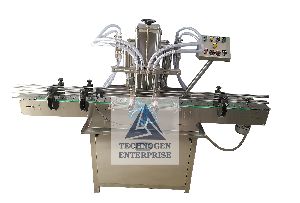

AUTOMATIC 4 Head VOLUMETRIC BOTTLE LIQUID FILLING MACHINE

275,000 - 350,000 Per piece

1 Piece (MOQ)

Semi Automatic Bottle Filling Machine

Get Price Quote

We are a credible Supplier of the Semi Automatic Bottle Filling Machine. Semi Automatic Bottle Filling Machine is the prototype electrically operated machine. Semi Automatic Bottle Filling Machine operates with a specially designed volumetric pump which is counted as its unique feature. In Semi Automatic Bottle Filling Machine, the volume of the liquid can be adjusted as desired within range of the pump. Semi Automatic Bottle Filling Machine can fill bottles of various types & sizes with high productivity. Semi Automatic Bottle Filling Machines are easy to operate, are portable and can be shifted from place to place saving both labor and time.

Indian Epoxy Filling Machine

150,000 Per piece

1 piece (MOQ)