Centrifugal Screen

Get Price Quote

We are offering Centrifugal Screen with round holes and slotted perforation. Precisely fabricated with brass & stainless steel, our Centrifugal Screen can also be provided with lock lap joints. Centrifugal Screen is used to screen the powdered compounds like spices, chemicals etc. Moreover, our Centrifugal Screen is available in various sizes to suit the diverse applications.

sugar screen

10,000 - 120,000 Per pc

1 Piece (MOQ)

Best Deals from Sugar Centrifugal Screens

Centrifugal Screen

Get Price Quote

We are involved in manufacturing, exporting and supplying a comprehensive range of Centrifugal Screen. Manufactured using brass metal comprising of oblong or round holes, Centrifugal Screens are high on demand in the national and international markets. This Centrifugal Screen is made available to the esteemed clients in different packaging as per the specification of the clients. Key Features Abrasion resistance Flawless quality Low maintenance cost Longer service life Durable Wear and tear resistant Application Sugar industry

Centrifugal Screen

8,000 - 25,000 Per pcs

10 Piece (MOQ)

CENTRIFUGAL WORKING SCREENS

Get Price Quote

We ensure that the delivery schedule should be properly maintained in order to meet the exact requirements of the customers. Due to our streamlined packaging system, we are able to meet standard as well as tailored packaging requirements of the patrons. Also, we guarantee complete safety of the products.Product Range of Centrifugal Screens : Working Screens : Having Conical Round Holes & Elongated Taper Slot in copper , Brass and S.S Metals and steepcone Basket Screens duly welded & silver Brazed with jointing Strips. Supporting/Backing Pattern : Wire Nettings , Plain & Dovex type Triangular stabbed with Round Hole, Stabbed Hole , Perforated & Corrugated in All Metals. Others : Sugar Grader Mesh , Mogensen Screens , Nickel Screens, DSM Screens, Bagacilo Screens Important Suggestions : All Screens for Centrifugal Machines Manufacture of costly metals ,variation of thikness direct effects its pricing ,consumption, durability, labour cost & economy of Sugar Mills. To avoid this pilferage and procurement of quality screens consider our suggestions as under : Prefer to purchase copper/brass screens at rate per K.G basis instead of per piece and verify thickness from weight chart. For durability and better results brass screens should be 63cu : 37zn and copper screens should be 99.9 purity. Stenless Steel Screens should be of 304 grades as specified in vaccum filter screens specification on back page.

sugar centrifugal screen

Get Price Quote

1 Piece (MOQ)

Sugar Processing Screen

1,900,000 Per Unit

1 Unit (MOQ)

Centrifugal Screen

Get Price Quote

Box type horizontal shifter is giving much higher out put from given screen area as compare to conventional oscillating (horizontal) shifter. Both end Polygonal box structure hollow shaft mounted on bushes. polygonal drum is made after fixing segmental screen. Horizontal blades with helical angle are fixed on paddle discs. Discs are mounted on shaft at regular interval and rotate inside. Blades traverse along whole length to give relative motion between screen and process material. Screw feeder feed material from inlet hopper into screen drum at feeding end. Processed material move from one end to other end with the help of helix blades. Material sieved from screen by centrifugal force imparted on particles due to rotating blades. Bottom Screw conveyor is attached below chute to collect fine material. Many outlet spout are provided along whole length to collect distributes fine material by bottom conveyor. Particals which are not pass through screen are conveyed to other end and come out from opening. Types of screen and opening of screen decide production rate.Advantages of CENTRIFUGAL SCREEN Unique design of screening is best for nonstop heavy production. It is very useful for heat sensitive and starch, flour, etc because particles are floats in air and help to reduce temperature. Blinding action on particles is reduces by centrifugal force.CENTRIFUGAL SCREEN is for Tridev Centrifugal Screen is continuous type rotary shifter to separate (classify) dry powder. It is used for screening product like Starch, Food product (colors), Spices, flours, Gum powder, Chemicals, Minerals, Agrochemicals, etc.

Centrifugal Screen

200,000 Per Piece

1 Piece (MOQ)

Sugar Centrifugal Screens

Get Price Quote

Sugar Centrifugal Screens

25,000 Per Piece

sugar screen

Get Price Quote

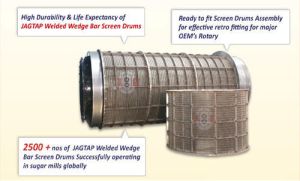

We are pleased to introduce ourselves as a leading suppliers and Exporter of Screens used in Continuous and batch Centrifugal Machines by Sugar Mills and refineries all over the world. We are proud to inform you that we are regularly supplying screens for sugar centrifugal of World's Prestigious Original Equipment Manufactures like BMA- Germany, Fives Cail -France, Western States- U.S.A., Thomas Broadbent - U.K., Hein Lehmann -Germany, Mausa -Brazil. Su Group - China.NHEC- India,Walchand Nagar- India,ThyssenKrupp -India,KCP-India etc. We also supply mud filters (vacuum filters),Rotory screens,wirecloth screens,perforated sheets,.

Sugar Centrifugal Screens

Get Price Quote

Sugar Centrifugal Screens, Sugar Centrifugal Screens

Centrifugal Screen

Get Price Quote

Centrifugal Screen, hydrapulper, Turbo Separator

sugar centrifugal screen

Get Price Quote

sugar centrifugal screen

Sugar Centrifugal Screens

Get Price Quote

Sugar Centrifugal Screens, Nickel Screens For Sugar Industry