Mini Sugar Plant

Get Price Quote

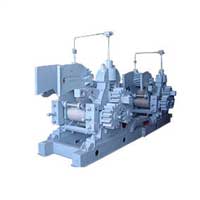

We bring forth an exclusive gamut of Mini Sugar Plants that is indigenously built and is machined headstock with fast assembly time. This captive power plant is manufactured by using cutting edge technology. These mini sugar mills are high on demand in the market and comply with the international standards. Apart from this, the Mini Sugar Plant that we offer can be availed at the most competitive prices. Appreciated For : Robust construction High durability Trouble-free performance Superior functionality Zero maintenance Capacity : 2000 TCD Download

Mini Sugar Plant

10,000,000 - 25,000,000 Per Piece

1 Piece (MOQ)

Best Deals from Sugar Plant

Sugar cane crusher Plant

295,000 Per Set

1 Set(s) (MOQ)

Sugar cane crusher manufacturer price for Jaggery Plant Om Kailash No. 2 Total Heavy - Single Mill - (F.B) with Planetary Gearbox & Motor Technical Specification Roller Length - 8½” Roller Dia 0- 8½” Capacity Per Day 25 - Ton Per Day 850 - 1050 Kg per Hour Crusher Pully - **** Coupling - 7-8 RPM Motor - 7.5 H.P Engine - ****

sugar plant

Get Price Quote

Mini Sugar Plant

2,000,000 - 2,500,000 Per Set

sugar plant

Get Price Quote

MATCON PRODUCTS AND SERVICES Matcon Products & Services We are a prominent manufacturer and supplier of paper mill machines. Along with this, we also have the facilities to meet the demands of chemical pressure vessels, storage tanks, chemical dryers, autoclaves, vanulath dryers and boiling house equipment. Our wide assortment is designed and manufactured using sophisticated facilities and high grade raw material in order to assure high productivity at the application areas. Some more details about our range are mentioned below: Matcon Industries has also Involved in manufacturing certain Equipments for Cement Manufacturing Industries like Grinding Mill, Raw Mill, Contineous type Ball Mill, Kiln, Cooler, Screw Conveyor, Bucket Elevater, Bearing Housing, Hoppers, Rotary Feeder, Table Feeder, Diverting Valves, Flap Valve, Vibratory Feeders etc..

sugar plant

Get Price Quote

sugar plant

Get Price Quote

Mini Sugar Plant

4,000,000 - 4,500,000 Per Bag

sugar plant

Get Price Quote

We are designing & manufacturing of sugar plant . We have a vast experience in sugar plant

sugar syrup plant

Get Price Quote

Mini Sugar Plant

Get Price Quote

We offer Mini Sugar Plant of 500 TCD capacity to the clients. The Mini Sugar Plant has the capacity of crushing 500 tons per day using the vacuum pan route and pressure-boiling route. In addition, the sugar produced from this Mini Sugar Plant is also similar to bigger sized plants and since availability of cane is from nearby sources of the plant, fresh cane can be crushed, which ensures better recovery. Salient Features : Low Capital InvestmentLess area under SugarcaneLess requirement of SugarcaneOperation & control of the plant will be easierThis is no levy to be paid to the government Specifications ModelSize of Roller in the Mill (Dia x Length x No. of Roller ) Inch x Inch x No.Capacity of Cane Crushing (Tons per Hour) Power Required (HP)ME- 12X14X912 X 14 X 9 Roller5115ME - 13X18X613 X 18 X 6 Roller7. 5100ME - 14X21X914 X 21 X 9 Roller10160ME - 16X24X616 X 24 X 6 Roller15135ME - 16X24X916 X 24 X 9 Roller20210ME - 18X30X918 X 30 X 9 Roller25280ME - 16X24X12 +FIB16X24X 12 Roller with TRPF/GRPF & Fibrizer25800ME -18X30X12 +FIB18X30X 12 Roller with TRPF/GRPF & Fibrizer381080ME - 20X40X12 +FIB20X40X 12 Roller with TRPF/GRPF & Fibrizer501500ME -24X40X15 + FIB20X40X 15 Roller with TRPF /GRPF & Fibrizer752500

Mini Sugar Plant

Get Price Quote

Complete Milling system like a modern sugar factory unit with the same efficiencies but small in size as per crush rate desired ranging from 300 TCD to 1500 TCD crush rate. There is high profile change in old mini sugar plants in efficiency (recovery), quality of product and cost of production. We have upgraded many old mini sugar plants into profit making units with innovative endeavor and continuous in house R & D. We have successfully installed numerous Mini Sugar Projects on Turnkey basis. We have to our credit successful installation of several new factories other than Mini Sugar Mills.

sugar plant

Get Price Quote

Guava Sugar Free Grafted Plant

Get Price Quote

Sugar Distillery Plant

Get Price Quote

sugar cane plant

Get Price Quote

Backed by a productive network, our company is able to cater to buyers all over Ankleshwar(India) and other Ankleshwar(India)s with ease. We are a buyer's best bet when it comes to purchasing Sugar Cane Plant. Our company is a promising supplier.

Mini Sugar Plant

Get Price Quote

We are the best manufacturer of Cane carrier, leveler, cutter, Fabrizor, Rake Elevator, Bagasse Elevator, Return Bagasse Carrier, Feed water Tank, Mill House Crane.

sugar plant

Get Price Quote

Cane CarrierThis is used to transport cane to the milling tandem, and consists of chains and slats. Its width is normally equal to the mill size.MillA cane-crushing unit having normally consisting of three rollers in a heavy steel housing. Cane first passes between the top and front rollers, then between the top and back rollers, to extract the juice.CrushersA cane crushing unit, preceding the first mill to crush the cane prior to extraction of juice, for the purpose of improving the quantity of juice extracted. Normally consists of two rollers.ShredderThis has the same purpose as the crusher, but a different principle. Consists of a drum, with a concentric shaft, on which hammers are mounted on arms.Mill TandemA complete mill is complex, consisting of crusher (or shredder) and all mills, together with drives and reducing gears.Cane KnivesThese are mounted on cane carriers prior to entrance to mills, for preventing entire cane stalks from entering the mills, straightening and precutting the cane, for the purpose of improving juice extraction and saving driving power at the same time.Intermediate CarriersThese transport the milled cane (bagasse) from one mill to the next. BAGASSE CARRIER This carries the bagasse from the last mill to the boilers, and its excess to storage.Power PlantThis produces electricity by means of non-condensing steam turbines, which drive generators. Juice HeaterA heat exchanger in which juice is heated by using steam as a medium, normally a multi-pass system. Juice flows through tubes, while steam passes along the outside of the tubes, in the cylindrical body.ClarifierIt is a large vertical cylindrical tank, where juice is given time for decantation, to separate the clear juice from the turbid, which still contains the mud. Juice flow is continuous.Drum FilterA device to separate the mud from the turbid juice; normally of the rotary vacuum type. , to let the juice pass and retain the mud on its surface.EvaporatorA series of vessels, in which excess water from the juice is evaporated to form a more concentrated liquid, now called syrup. The vessels work in series under increasing vacuum conditions, to reduce the boiling temperature gradually as the concentration increases step-wise. This prevents overheating of juice and loss of sucrose. The vessels together form a triple-, quadruple- or quintuple-effect evaporator.Vacuum PanSimilar to an evaporator vessel, a continuation of the evaporating process, but carried so far that crystallization occurs. Also boils under vacuum for reduced boiling temperature. The syrup is now transformed into massecuite , which is a mixture of crystals and molasses.CrystallizerA strike receiver in which the charge from the vacuum pan is stored before going to the centrifugals. Its purpose is cooling, to increase grain size and reduce sucrose left in molasses.CentrifugalA machine with a fast spinning drum and a screen, inside, through which the molasses can pass while the crystals are retained. Separation is based on the difference in specific gravity, amplified by centrifugal force.DryerA long drum-like rotating cylinder, where sugar is brought in contact with heated air, to reduce its moisture content.CoolerSame as a dryer, but air is dry and cooled to reduce temperature of sugar, heated by the dryer. This is to prevent caking during storage. The combination of dryer an