Double Surface (Davies) Condenser CORNSIL

Get Price Quote

50 pcs (MOQ)

Steam Surface Condenser

Get Price Quote

The Steam Surface condenser is a critical component of both the traditional coal fired power plant and the new generation cogeneration and combined cycle power plants. Main duties of any Surface Condenser are to convert the exhaust steam from its gaseous to its liquid state at certain under atmospheric pressure, and also, to release non-condensable presented in the steam cycle, together with vacuum unit.Jet Flow designs and economically sized condenser suitable for smaller turbine ratings under 100 MW. The circular configuration is compact for easy shipping and maintains the level of quality afforded all of our condenser designs.All of Jet Flow’s Surface Condensers are designed and built to the Heat Exchange Institute latest Standards.We also strive to meet all of our client’s project specific requirements. Our Condenser design can incorporate enhanced deaeration systems, and or a variety of turbine exhaust options including Axial and Top steam inlet design, which can assist greatly in improving plant layouts. We continually address and refine these and other considerations associated with circular designs where space is at a premium.Jet Flow Surface Condensers are fabricated in-house state of the art fabrication facilities located in Ahmedabad. All of the fabrication facilities are according toASMEcode and an impeccable reputation for quality fabrication and on time delivery. Our Surface Condensers feature high overall heat transfer coefficient (which result in smaller heat transfer areas and thus optimal use of the available space) and extremely low oxygen concentrations in the condensate. They are designed to stand up to turbine and steam generator overloads and to variations in cooling water temperature at different times of the year.Jet Flow Surface Condenser highlights: Effective steam distribution within tube nest Uniform distribution of heat loading Effective collection and removal of noncondensable gases Negligible condensate subooling Minimized condensate inundation Lower velocity fluctuation Efficient air cooling section Effective de-aeration performance One orTwo passes. Down Flow, Axial flow or side inlet design. 4 to 6 months delivery. Available for all type ofTurbines. Air cooling zone is provided in the coolest part of the condenser, which minimise the carry overof the steam to the ejector vacuum system alongwith the non condensable gases.Geothermal Steam Condensers:Jet Flow has many years of experience designing vacuum Condensers with high non-condensable loads. Since Geothermal steam is highly corrosive and contains large amounts of non-condensable gases, the design and fabrication of Geothermal Steam Condensers is radically different than conventional power plant condensers. Special attention to be given on reduced overall heat transfer rates and LMTD due to high amount of non condensable gases, pressure drop, sub-cooling, flow path for venting large volumes and material selection to prevent corrosion. Associated vacuum system is Multi stage Steam Ejectors with direct OR in-direct type inter condensers.

Best Deals from Surface Condenser

Surface Condensers

Get Price Quote

You can make payments through online methods such as net banking, PayPal, or offline methods such as draft depositing, cash on delivery etc. Our policies regarding payment are swift and transparent. We are working with a team of deft professionals who manage the entire task proficiently and lay special emphasis on product packaging so as to ensure safe and secure deliveries.

Steel Surface Condenser

Get Price Quote

The company provides Steel Surface Condenser which is currently the most popular type of Condenser used worldwide. We provide Steel Surface Condenser that serves its benefits in several types of applications. Steel Surface Condenser provided by us is manufactured using high quality materials and the most developed techniques. We provide Steel Surface Condenser to buyers, at the most attractive prices. Highlights Corrosion resistantRust resistantMarket competitive pricesDurable and efficient.

Surface Condenser

1,250,000 Per Piece

GLASS DOUBLE SURFACE CONDESNOR NARAYANI

Get Price Quote

10 Piece(s) (MOQ)

We have a good rapport with the prominent e-commerce merchants who provide us a secure payment gateway. With this, we guarantee instant and hassle free transactions. We are among the trusted names, involved in offering world-class lot of Double Surface Condenser in the national market. The double surface condensor have a red colour connection to avoid the breakage of the glass . It have differnet sizes like 150 mm , 200 mm , 250mm , 300 mm dia , 350 mm , 400mm with diferrnt joint s liike B 14 , B 19 , B 24 , B 29 , B 34 etc .

Surface Condensers

Get Price Quote

Our warehouse is well constructed and equipped with all required amenities essential for a safe storage of the products. We also make sure that proper hygienic conditions should be maintained inside the unit. With strong industrial experience, we make sure that the packaging is done as per the stated norms, by this; the products that we deliver are absolutely safe from the getting damaged.

Davice Condensers, Double Surface

Get Price Quote

We are manufacturer and exporter a best quality of laboratory glassware. Based in Haryana, we are primarily engaged as the Manufacturer, Supplier and Exporter of Davice Condensers, Double Surface in country and abroad. Our precision Davice Condensers, Double Surface are fabricated using premium material, which is procured from reliable sources. Their quality and durability is quite high, which makes them desirable. Plus, we offer theseDavice Condensers, Double Surface in required specifications at market-leading prices. We ensure safety while transit through meticulous packaging! Length mm. � 150 � 200 � 250 � 300 � 400 � 500 � 600

Double Surface Condenser

Get Price Quote

500 Pieces (MOQ)

Double Surface Condenser

Get Price Quote

Symbolic to all the success that we have acquired in the market, remains our status as a prominent organization of an exceptional variety of Double Surface Condenser. In order to manufacture this condenser, our talented professionals utilize quality assured material and contemporary technology. Owing to its splendid features like superb strength and crack resistant, this condenser is very much demanded by our valuable clients.

Surface Condensers

Get Price Quote

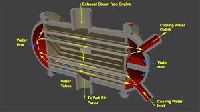

A surface Condenser is a commonly used term for a water-cooled shell and tube heat exchanger installed on the exhaust steam from a steam turbine in thermal power stations.These condensers are heat exchangers which convert steam from its vapour to its liquid state at a pressure below atmospheric pressure.

Surface Condensers

Get Price Quote

VHEPL Steam Surface Condensers range from small packaged units used in the HVAC industry to large cylindrical condensers used for mechanical drive applications in power plants, refineries, or chemical processing plants. Circular shells to approximately 12 feet in diameter can be supplied to suit a variety of requirements. Because of our considerable experience in condenser manufacturing, our ability to work with exotic materials as well as turbines with different exhaust configurations (down, top, axial), We can closely work with customers to evaluate options that best meet the specific requirements of any project. We manufacture wide range of Surface Condensers & Steam Heaters for Power Plants.

Surface Condenser

Get Price Quote

Steam Condensers found in power plants and are provided after the turbine to condense the steam and recycle the same as boiler feed water to Boilers. Small Size Steam Condensers complete with water boxes are manufactured by us. We carry out both Thermal & Mechanical design and then manufacture the complete Steam Condensers with water boxes as per the applicable codes. Generally the Tubes used in Steam Condensers are of Admiralty BrassCupro-Nickel (9010)SS 304 quality depending upon the type of cooling water available, while rest of the material is of Carbon Steel. Re-tubing of the Steam Condensers at site is also undertaken. We have ample manpower, tools and tackles & skills to undertake the same. We can complete the same also within the stipulated amount of time by working day and night.

Gland Vent Condensers and Surface Condensers

Get Price Quote

Suited for condensation of gland vent steam and main steam after expansion in turbines. Gland vent condenser is provided with centrifugal blowers to force the air out after steam is condensed. Surface condensers from 1 ton to 10 ton capacity are custom-built with features such as connection for rupture disc, recirculation nozzles, hot well and its connections, connections for instrumentation including level gauges, flash pipe with relevant connections and stand pipe with required connections. Condensers designed as per HEI standards and recommended good practices.

Surface Condenser

Get Price Quote

The Company mainly manufactures two categories of products: equipment for power plants, including pulverized coal-fired (PC) boilers, heat recovery steam generators (HRSGs), surface condensers, feed water heaters, closed cooling water (CCW) heat exchangers, boiler coils, boilers, deaerators and others, and equipment for steel plants, including recuperators, coke dry quenching (CDQ) boilers, waste heat recovery systems, steel making plant boilers, reactors, oxygen plant heat exchangers and others.

Surface Condensers

Get Price Quote

We have supplied several surface condensers to our valuable clients on a regular basis. The largest condenser manufactured by us to date is for Jindal Steel Works (Captive Power Plant) which comprised of 14000 tubes.

Surface Condenser

Get Price Quote

These gases can also result from caused by the decomposition of water into oxygen and hydrogen by thermal or chemical reactions. These gases must be vented from the condenser for the following reasons: The gases will increase the operating pressure of the condenser. Since the total pressure of the condenser will be the sum of partial pressures of the steam and the gases as more gas is leaked into the system, the condenser pressure will rise. This rise in pressure will decrease the turbine output and efficiency. • The gases will blanket the outer surface of the tubes. This will severely decrease the heat transfer of the steam to the circulating water. Again, the pressure in the condenser will increase. • The corrosiveness of the condensate in the condenser increases as the oxygen content increases. Oxygen causes corrosion, mostly in the steam generator. Thus, these gases must be removed in order to extend the life of cycle components.

Industrial Surface Condenser

Get Price Quote

Surface Condenser

Get Price Quote

New field surface condensers are planned to condense turbine exhaust steam in power generating or mechanical drive applications. The condenser produces a vacuum at the turbine discharge raising the overall cycle efficiency. New field condensers have proven to be reliable and are chosen for applications all over the world, including installations in chemical processing plants, refineries, marine applications, and power generation facilities. A variety of fabrication in Chemical processing plants,refineries,Marine applications and power Generation Units.New Field Provides Varieties of fabrication options, materials, and configurations are employed to satisfy today's challenging technical requirements.

Surface Condenser

Get Price Quote

Surface Condensers are engineered and designed for cooling exhaust steam for back pressure turbine as well as for condensing type turbine. These condensers are multi-pass and high velocity shell and tubular heat exchangers. The advantage of these condensers is its ability to eliminate the mixing of cooling and condensed water.