single punch tablet press machine

55,000 Per Piece

1 Piece (MOQ)

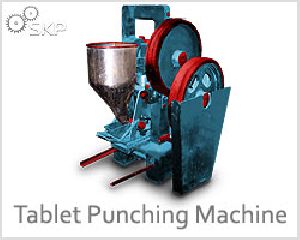

Tablet Punching Machine

Get Price Quote

The Different Types Of Tablet Press Tablet machines, also called as compressing machines or tablet presses, are the equipment used to compress the powder into its tablet form forming uniform size, shape and weight. The compressing machine may also be used for manufacturing of other tablets such as for cosmetics, cleaning products and pharmaceutical drugs. The compression machine tooling determines the shape, identification marking as well as the size of the tablet. Each of the tooling set includes upper and lower punch as well as dies. As many of the tablets are formed by these equipment, the latter must meet several guidelines in order to produce uniformity in terms of dosage, aesthetic appearance as well as production efficiency.

Best Deals from Tablet Punching Machine

Tablet Punching Machine

Get Price Quote

A Tablet punching machine is used to push the medical powder inside of the tablets of uniform size and shape. These systems are used mainly in pharmaceutical industries. Tablet Tools India, being a top-notch manufacturer, supplier and exporter of tablet punching machines in India, used only best quality materials from reputed vendors and offers the clients with global quality tablet machines, made with every precision and excellent artistry, which enables the machines to have long life, and it also helps the machines to reach the peak performance. They generally have long lifetime with giving peak performance every time.

Tablet Punching Machine

Get Price Quote

In the tablet-pressing process, it is important that all ingredients be fairly dry, powdered or granular, somewhat uniform in particle size, and freely flowing. Mixed particle sized powders can segregate during manufacturing operations due to different densities, which can result in tablets with poor drug or active pharmaceutical ingredient (API) content uniformity but granulation should prevent this. Content uniformity ensures that the same API dose is delivered with each tablet. Tablets are simple and convenient to use. They provide an accurately measured dosage of the active ingredient in a convenient portable package, and can be designed to protect unstable medications or disguise unpalatable ingredients. Colored coatings, embossed markings and printing can be used to aid tablet recognition. Manufacturing processes and techniques can provide tablets special properties, for example, sustained release or fast dissolving formulations

Tablet Machine (single punch)

Get Price Quote

We are the main supplier of this product.

Multi Punch Tablet Machine

Get Price Quote

Our valued customers can avail from us precision-engineered Multi Punch Tablet Machine. We are a Supplier of Multi Punch Tablet Machine, operating from Uttar Pradesh. Multi Punch Tablet Machine comes with multi punch dies of different sizes and shapes along with electrical & V-belts. Multi Punch Tablet Machine, which we offer is easy operate and maintain.

Tablet Punching Machine

Get Price Quote

shri krishnaji tablet punching machine has following salient features gravity feeding system two piece turret upper roller with penetration adjustment system control panel with bypass switches control panel with separated display for tablet count and rpm fixed hopper with slide to control powder flow hand wheel provided re-designed variable speed pulley cam tracks and pressure rollers made out of alloy steel for maximum wear resistance and long life. Worm is made up of phosphor bronze machine is totally enclosed i.e. Top half of the machine (compression zone) with ss hood, acrylic covers in skp model. This reduce the noise level and to and fro flow of dust between compression zone and machine room. higher speed 15 to 35 rpm phosphorus bronze bush provided inside the turret hole ss guards lower punch cam can be removed without dismanting the lower roller assembly. optional features double layer attachment electro nickel including nickel die plate lower punch key way for break-line/ embossing alignment

Tablet Punching Machine

Get Price Quote

We are offering Tablet Punching Machine that is uniquely designed for easy maintenance and is offered at industry leading prices. Our Tablet Punching Machine can be operated both by manual means and hand. In our Tablet Punching Machine a tablet is formed by the combined pressing action of two punches and a die. We are a prominent Tablet Punching Machine Exporters and Suppliers in India.

Multi Punch Tablet Machine

Get Price Quote

1 Piece (MOQ)

Tablet Punching Machine

Get Price Quote

We are offering tablet punching machine. we offer tablet punching machine that can be availed in various models with difference in production capacity as well as h. P. Also, the tablet punching machine provided by us is customized as per the varied requirements of the customers in terms of material used, etc. features : enclosed structure reduced noise level maximum wear resistance longer service life to and fro dust flow between machine room and compression zone speed 15 to 35 rpm optional availability electro nickel with nickel die plate double layer attachment lower punch key way used for break-line or embossing alignment components : gravity feeding system ss guards easily removable lower punch cam control panel bypass switches separated display for tablet count rpm fixed hopper available with slide to control the powder flow cam tracks and pressure rollers (alloy steel) worm is made up of phosphor bronze hand wheel re-designed speed pulley compression zone ss hood acrylic covers in skp model. phosphorus bronze bush inside the turret hole lower roller assembly

Tablet Punching Machine

Get Price Quote

Tablet Punching Machine

Get Price Quote

Provided with double sided lifting cams. Extra hand wheel is provided for easy loading of punch die sets.There is not any painted parts in tablet manufacturing zone as all parts are made of stainless steel 304 or gunmetal or of hard chrome plated. All hardware used in the machine has stainless steel 304 quality in tablet manufacturing zone.Lower guard of polished stainless steel and upper guards of acrylic material. Turret guards have sturdy aluminum frame. All guards are interlocked for safety.

Hydraulic Punch Tablet Press Machine

Get Price Quote

Tablet Punching Machine

Get Price Quote

Many model our manufacturing range Compression Machine For Tablets , Tablet Manufacturing machine, Pill Pressing Machine ,Bilayer Tablet Compression Machine, Automatic Tablet Press Machine, Single Sided Rotary Tablet Press , Tablet Punching Machine , Tablet Press Machines such as Single Rotary Tablet Press Machine, Next Gen-1 Heavy Duty Tablet Machine and Rotary Tablet Press Machine, High Speed Double Sided Rotary Tablet Press such as Double Sided Rotary Tablet Press, Rotary Tablet Press Machine, Tablet Press Model Tablet press machine Mega Press and Tablet press machine Press IV, Double Sided Rotary Tableting Machine such as Tablet Press Machine, Salt Tablet Press Machine, Double Rotary Tableting Machine and Tablet Press Model .

Single Punch Tablet Punching Machine

Get Price Quote

We introduce ourselves as a customer driven and quality focussed manufacturers and exporters of single punch tablet punching machine that is uniquely designed for easy maintenance and offered at industry leading prices.

Tablet Punching Machine

Get Price Quote

Cemach Limited specializes in the manufacture of Pharmaceutical Tablet Compression Machine, also popularly known as Tablet Press. Cemach Limited is one of the largest manufacturer and exporter of Tablet Press Tooling Machine Series of cams, punches and rollers makes up Tablet Compression Machine, sometimes mechanical devices are added for filling and ejecting Tablets. All the spares are precisely crafted and made from high quality materials which are corrosion free and robust. Cemach Limited is also expert in manufacturing containers which are important for precise weight control. Whether you want to produce vitamin Tablets or Ayurvedic Tablets, or cosmetic products, whether you need a single station tablet press ,single-station double station, high speed tablet press, manually operated Tablet press, or a heavy-duty, high-output, automated Tablet press, You can buy tablet press according to your need from our dynamic range of Pharmaceutical Tablet Press.

Tablet Punching Machine

Get Price Quote

We are the leading tablet machine manufacturers and exporters based in India selling wide range of equipment that has the capability to produce tablets from 250,000 to more than 1,000,000 every hour. We do also provide customized solutions for various Pharmaceutical machines like tableting machines, Strip Packing Machine, filling machine and Blister Packing Machine based on industry needs and requirements. The flawless range of our tableting machine India makes sure that our products are highly efficient and cost effective when compared to other similar products in market. We always employ most sophisticated tools and technologies to manufacture our products.

Tablet Punching Machine

Get Price Quote

The product becomes contaminated with metal from broken punch tipe. Broken punch tips, produces deformed tablets, which can lead to rejection by Quality Control. Tablets are ground up and reprocessed and this ultimately leads to costly reworking of the tablets. Higher quantities of broken tablets are present in waste output of sorter (tablets are not reprocessed). Labor costs are increased, which could result in higher prices to users and ultimately effects the product’s competitive position in the marketplace. Time is lost in distributing the product, which could delay introducing a new product or cause a purchaser to run out of an existing product. Some shaped tablets break easily when fed through the sorter or tablet filler

Tablet Punching Machine

Get Price Quote

Shri Krishna tablet punching machine has following salient features Gravity feeding system Two piece turret Upper roller with penetration adjustment system Control panel with bypass switches Control panel with separated display for tablet count and RPM Fixed hopper with slide to control powder flow Hand wheel provided Re-designed variable speed pulley Cam tracks and pressure rollers made out of alloy steel for maximum wear resistance and long life. Worm is made up of phosphor bronze Machine is totally enclosed i.e. top half of the machine (compression zone) with SS hood, acrylic covers in SKP model. This reduce the noise level and to and fro flow of dust between compression zone and machine room. Higher speed 15 to 35 RPM Phosphorus bronze bush provided inside the turret hole SS guards Lower punch cam can be removed without dismanting the lower roller assembl Optional features Double layer attachment Electro nickel including Nickel Die Plate Lower punch key way for break-line/ Embossing Alignment

single punch tablet press machine

Get Price Quote