Cube Testing Machine

Get Price Quote

We offer cube testing machine that is quality-tested as per international standards. Our cube testing machine is designed as the requirements of diverse industries. Cube testing machine that we provide are highly efficient and easy to operate. We provide cube testing machine at competitive rates.

Spring Testing Machine

Get Price Quote

Best Deals from Testing Machines

Ductility Testing Machine

30,000 - 80,000 Per Piece

1 Piece (MOQ)

AT- 231 Ductility Test Apparatus As Per IS 1208–1958 electrically operated, Inner Chamber made up of Stainless Steel fitted with pump for circulation of water 230V AC Single Phase.

Latest Eye Testing Machine

280,000 Per piece

1 piece (MOQ)

Hydro Valve Testing Machine

200,000 Per Piece

1 Piece (MOQ)

Valve Testing Machine

Get Price Quote

1 Unit (MOQ)

X-RAY XDAL-237 Gold Testing Machine For Hallmarking Centres

Get Price Quote

semi automatic Servo Compression Testing Machine

Get Price Quote

1 Piece (MOQ)

Our semi automatic compression test machine is available from 100 Kn to 3000 KN Load frame frame can be supplied, in Chanel type, 4 pillar type, Plate type Provided with software. speed controlled by control know/simulator. power required 440V, AC supply, 50 Hz

Computerised Compression Testing Machine

600,000 - 4,000,000 Per Piece

Tensile Testing Machine

Get Price Quote

1 Piece (MOQ)

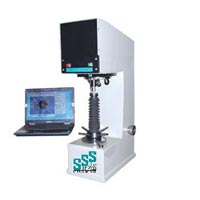

Computerized Vickers Hardness Testing Machine

250,000 - 800,000 Per

1 Set(s) (MOQ)

Our Computerized Vickers Hardness Testing Machine is efficient in estimating the Vickers hardness number by measuring the diamond’s indentation in an automated way. The result is simply to draw and is accurate enough to rely upon. It is also ideal for estimating the hardness of various metallic components. It is set in absolute accordance with IS 1754 – 2002. We are emerging as the promising Manufacturer and Supplier of Computerized Vickers Hardness Testing Machine in Maharashtra. The Software Includes : Online indentation setting and focusing on PC monitor Facility for Auto / Remote Auto / semi Auto / Manual modes of operation Well managed database saves readings W.R.T. batch and certificate Report generation in the form of certificate and graph with variation and histogram Facility for calibration and check of calibration Advance image processing algorithm implemented for automatic measurement Statistical data is provided for a batch results and include standard deviation, mean, medium, minimum and maximum reading Measuring scale Calibration / Verification on PC monitor PC Requirements : 1.8 gigahertz (GHz) or faster processor 1 gigabyte (GB) RAM minimum Microsoft Windows XP operating system Display screen resolution minimum 1024 by 768 pixels Two free USB 2.0 ports Free update of software for Windows 7/8 in near future NOTE : DUE TO CONSTANT R&D SPECIFICATION AND FEATURES ARE SUBJECT TO CHANGE WITHOUT NOTICE.

Shock Test Machine

Get Price Quote

The machine is fabricated with Mild steel of a very robust design to provide necessary mechanical strength and rigidness. The machine produces the shock pulses using compressed air to force the platform to impact on the elastomer pads (Half-Sine Programmer Pads)which are placed between the platform and anvil of the impact area to produce half-sine pulses, Lead pellets are placed to generate sawtooth pulses and pneumatic cylinders are used to generate square pulses. The drop height and the air pressure are responsible to generate the desired acceleration.Shock Test Machine is a versatile test equipment to carry out shock tests in accordance with various National & International standards e.g. IS, MIL, EN, ISO, IEC, DEF & ASTM Standards.The lifting of the platform is done by pneumatic cylinders, the drop height is determined by the desired acceleration level. In a shock test due to the rebounce action secondary shocks may occur, which are totally unacceptable by most of the test standards. Fail safe brakes are used as a rebounce brake and as a quick release device to avoid secondary and tertiary shocks. The shock test machine is isolated from the ground by heavy duty shockers and shock absorbers. The Shock test machine is supported by a PC based intelligent Instrumentation system to control, monitor and analyse acquired shock test waveforms. The system has 4 channels to monitor the shock pulses generated which are expandable upto 16 channels. Advantages for you Customizable Reliable Solutions:Key features Heavy duty structure Adjustable drop height Standard 4-channel signal conditioner upgradable to 16-channel Adjustable Acceleration and pulse duration Use of Shock Amplifier can be made to increase the change in velocity & acceleration upto 30,000 'g' Capable to perform tests in accordance with various standards eg. IS, MIL, DIN, ISO, EN, IEC, DEF, JS55555 & ASTM etc. Efficient performance:Key features Pneumatic operation with low maintenance requirement Fail safe brakes for no Secondary or Tertiary Shocks Shock Response Spectrum Analysis Shock tests in accordance with various international standards Shock Response Spectrum Analysis Shock tests in accordance with various international standards Highly accurate repeatability Ground is isolated from bumps generated User Friendly:Key features PC based control, monitoring and waveform analysis Various safety interlocks for safe operation Report generation feature PC Based Instrumentation SystemShock-Test-Machine-control Tarang PC based instrumentation system provides an easy control, monitoring and waveform analysis to be done. The control of the machine is very user friendly and incorporates various safety interlocks for safe operation of the machine. The test report of any test performed can be viewed and printed easily. The Shock Analysis software is specially designed for the analysis of waveforms generated. Shock Response Spectrum Analysis can also be done with this software.

TTA-10 Torsion Testing Machine

Get Price Quote

1 Piece (MOQ)

Hydrostatic Pressure Testing Machine

Get Price Quote

Advance Hydrostatic Pressure Testing Machine are available with advance technology as per different application for the test of internal pressure of R-PVC, C-PVC, U-PVC, MDPE, HDPE, LLDPE, PP-R pipes, Fittings, Valves etc. as per ASTM, BIS, ISO, DIN, IS and other equivalent standards.

Ductility Testing Apparatus

23,000 - 28,000 Per Piece

Tensile Material Testing Machine

Get Price Quote

We offer supreme quality Tensile Material Testing Machine characterized with precision screw and column construction and variable speed drive. The Tensile Material Testing Machine is suitable for studying mechanical behavior of various materials like metals, polymers, elastomers etc. The Tensile Material Testing Machine confirms to IS, BS & ASTM standards.

Cube Testing Machine

100,000 - 200,000 Per piece

1 Piece (MOQ)

micro vickers hardness testing machine

500,000 Per Piece

Cube Testing Machine

Get Price Quote

KFG-01 Manual Spring Testing Machine

Get Price Quote

Please contact factory for more details

Injector Cleaning & Testing Machine HIM 125

Get Price Quote

Machine can CLEAN up to 4 Injectors simultaneously for all type of MPFI vehicles. Tank capacity is 2.5 Ltrs. and weight of the machine is 15 kgs. Approx. with empty tank. Machine will operate only on 12 V DC@ 15 Amp. Battery supply. An attendant has to be present on the machine at the time of cleaning.

LTJM 2099 Rice Testing Machine

18,000 - 35,000 Per piece

1 Piece (MOQ)

Lab Dyeing Testing Machine

Get Price Quote

We, as a Manufacturer, Exporter & Supplier, are involved in offering Lab Dyeing Testing Machine. Lab Dyeing Machine on offer is durable and robust. Our team of well trained staff keeps manufacturing process under stringent supervision to ensure our quality is in conformity with different standards set by industry. Hence, our customers can rest assured of the quality. We offer a range of designs and specifications. Specifications IR Beaker dyeing machine Works on the principle of infra red heating. Suitable for high rate of rise in temperature. Capacities - 12 x 250ml, 16/18 x 250ml, also in 500ml, 1000ml. Equipped with microprocessor based temperature programmer &, Air cooling. Optional - Variable speed drive HTHP Beaker dyeing machine Double wall SS Structure with Glycerin Bath. Capacities - 12 x 250ml, 16/18 x 250ml. also in 500ml, 1000ml. SS 316 jars. Heating – 3x 2.5kw. Microprocessor based temp. programmer & Water cooling through copper coil. Optional: Variable speed drive. Rota Dyer Suitable for cotton dyeing. Double wall structure. Capacities - 12 x 250ml, 16/18 x 250ml. also in 500ml, 1000ml. heating -3 x 2.0kw, digital TIC cum Timer. Open bath beaker dyeing (Atmospheric beaker dyeing machine) Suitable for below 98°C dyeing. Capacities - 12 x 250ml, 16/18 x 250ml or 500ml. Heating - 3x1.5kw, up/down & also to & fro movement of rods. Water circulation pump for uniform temp. in bath. Water bath Fully SS structure, capacity: 6 x 500ml, 12 x 500ml. with digital TIC. Jars of SS 316. Hot Air Oven Upto 200°C. standard Size: 18” x 18” x 18”. With digital TIC & Air circulation fan. 2nos jail type trays. Heater – Tubular finner air heaters of 2kw. Indigenous table top type models-Auto temperature compensation – supplied with. Colour Matching Cabinet Available in ECO/Standard/Premium Model in 2ft & 4ft sizes. Metal body, light Sources - D-65, TL-84, CWF, TL-83, UV, U-30, U-35, Illuminant A, Filament Bulb. Water Bath Shaker, Capacity - 12 x 250ml with speed regulator Lab Shaker – Capacity - 9 , 16 flasks of 250ml, with Timer & RPM indicator Hot Plate – 1000w, Dia-8” Shade Card Winding Machine Tailor made equipment as per size of card/no of strips/width & spacing of strips. Padding Mangle. Roll Size 120mm X 300 Mm: For Cool Padding Maximum Working Width - 300mm. Roll Size - Diameter 120mm X 300mm B.O.D. Incubator – Capacity 18” x 18” x 24” X-Rite Portable Spectrophotomer X-Rite (Macbeth) Color Matching Cabinet Note : For More Information Visit at Our Website www.vgoindia.com.

Tile Abrasion Testing Machine

Get Price Quote

1 Piece(s) (MOQ)

Ductility Testing Apparatus

26,500 - 32,000 Per Piece

1 Piece (MOQ)

Tile Abrasion Testing Machine

Get Price Quote

Our Tile Abrasion Testing Machine is fabricated as per IS: 1237 and 1706. Tile Abrasion Testing Machine offered by us consists of a grinding path fixed to a rotating disc, which is enclosed by a circular tray. Herein, the tile sample is compressed against the grinding path, which is revolving at the rate of 30 ± 1 revolutions per minute. Tile Abrasion Testing Machine, that we offer, is attached with automatic preset counter to rest the machine after 22 revolutions. Tests the Resistance Against Abrasion of Crushed Rock Crushed Slag Crushed Gravel Uncrushed Gravel As specialists in manufacturing and supplying Tile Abrasion Testing Machine, we are bent on providing our customers 100 percent satisfaction.

laboratory testing machine

Get Price Quote

We offering different Laboratory equipments which are durable in construction, these products find their usage in various industries for conducting regular testing and Quality control.

Computerized Universal Testing Machine

450,000 - 480,000 Per Piece

1 Piece (MOQ)

Spring Testing Machine

60,000 - 65,000 Per Piece

1 Piece(s) (MOQ)

Digital Hydraulic Spring Testing Machine is mainly used to make test on helix spring for tension and compression purpose. This machine is designed for conducting load-deflection test on spring or other material in tension or compression. In addition to this, the rugged construction and extreme simplicity make it easy for a also a non-technical personnel to operate it without any hassle. Manufactured using supreme quality steel material and other components these products are perfect to determine Feature. Digital load indicator on the spring test equipments connected to a load cell Electro-mechanical loading system with lead-screw at fixed or variable The spring test equipments shall have one load cell. Zero result facility for length indicator at any position of top platen, to indicate the actual deflection during loading Microprocessor of the spring test equipments shall have load and deflection display

Lada XRF-10 Gold Purity Testing Machine

538,000 Per piece

1 Piece (MOQ)