Linter Cleaner

Get Price Quote

Working principle of Linter Cleaner Linter is discharged from a cyclone to the top chamber of the LC-410D Linter Cleaner. This chamber consists of two x 3 Meter' long, 500 MM diameter cylindrical beaters operating side by side in 550MM dia. Half round screen sections. Linter enters at one end of one beater, is conveyed to the opposite end and transferred to the opposite beater section. From this point, the Linter is once again conveyed over the screen section for the length the top section. Cleaned Linter discharged from the top section is pneumatically conveyed to the bale press. Any Linter, which passes through the perforated screen of the top section, along with trash, is discharged into the first of the two pepper sections. These sections are clothed with fine wire mesh for the removal of the very fine hull particles (hull pepper) generated in the saw delinting process. Linter then passes to the reclaim section for final cleaning.The reclaimed Linter is then discharged and may be conveyed to a motes beater or recycled to the Linter cleaner. In addition to the 6 Meters of hull pepper removal screens the, LC410D also incorporates Automatic Screen Cleaning which blows down the entire length of both hull pepper sections with high-pressure air. Manual blow-down and unnecessary shutdown are eliminated. This also provides for consistent length of effective cleaning throughout the daily operations. This blow down system is PLC controlled and can be programmed for both duration & frequency of the air blasts. Salient features of our Dryer Lint Cleaner Maximum cellulose yieldCapacity – 15 TPD Linter28% greater cleaning surface area for first-pass cleaning than othersAdditional cleaning where needed most; three times the effective pepper section cleaning than the closest competitorReclaim section designed to accommodate any additional shale removal which may be required.Automatic screen cleaning; programmable to specific requirements

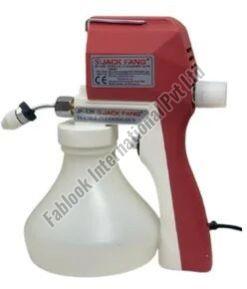

stain removing machine

Get Price Quote

We settle the demand for Stain Removing Machines, from anywhere across the country and abroad, with the machines that conform to all the applicable standards. We are a renowned Manufacturer, Exporter, and Supplier of Stain Removing Machines from Punjab, India. We make use of the best quality materials and components and use inventive ideas to design and develop them. Plus, quality is an assured thing in which our products stand high. Other Information : Stainless steel large station with fine mesh. Nose basin. Narrow swiveling sleeve arm also of stainless steel. Ecology suction filter. Stainless steel rack for solvent containers. Main solvent containers connected to compressed air. Concealed lighting device. Adjustable overhead tubular frame for spring loaded spotting guns. Mounted on sturdy spray galvanized & hot painted chassis. Long rust free life & sheen. Ecology suction keeps working area nontoxic & user friendly. Powerful suction through a centrifugal blower activated by spring loaded full length foot pedal working in conjunction with sturdy micro-switch & electric contactor Spotting guns. Steel forged imported. Optional electro pneumatic portable spotting gun. Maintenance free long life. Steam air gun for hot spotting .imported .heat proof handle with soft micro switches for, steam, air & steam air combination. Working in conjunction with steam –air manifold. Easy to use.

Best Deals from Textile Cleaning Machine

Textile Spot Cleaning Gun

2,070 Per Piece

1 Piece (MOQ)

Stain Removal Machine

75,000 - 95,000 Per piece

1 Piece (MOQ)

stain removing machine

Get Price Quote

Being a quality-oriented entity, we are highly engrossed in offering Stain Removing Machine to the clients. We carry out our operations from Haryana, India. We strive to attain the optimum satisfaction of our clients by making timely deliveries of our consignments. Its efficient functioning, perfect finish, great performance, and long working life are highly praised in the market. We offer it at the leading market rate.Details : It is an Indigenous Machine with imported spare work on the latest cold spotting principle. It can be operated even by unskilled worker Easy availability of spare and comprehensive service stainless steel body prevents rust and distortion of fabric stainless steel suction table & Movable side small arm for small Tubular garments

Electrical Screen Washer

85,000 Per Unit

1 Unit (MOQ)

Nova Lint Remover

Get Price Quote

lint remover

270 Per piece

Arrow CM-16 Textile Spot Cleaning Gun

Get Price Quote

10 Box (MOQ)

Mini Lint Remover

56 Per piece

100 piece (MOQ)

Textile Cotton Cleaning Machine

100,000 - 3,000,000 Per piece

1 piece (MOQ)

textile cleaning gun

Get Price Quote

1 Piece (MOQ)

Cotton Lint Cleaner

Get Price Quote

1 Piece (MOQ)

stain removing machine

100,000 Per Piece

1 Piece(s) (MOQ)

lint remover

190 - 199 Per piece

1 Bag (MOQ)

Washing machine Lint remover

SEVEN STAGE LINT CLEANER

1,750,000 - 1,800,000 Per

stain removing machine

90,000 Per 85000 Piece

1 Piece(s) (MOQ)

Technical Features The Steps Stain Remover Equipment will remove practically all stains by shooting compressed air and chemical at the stain. A hot air and steam gun enables removing of tough to remove stains. These are manufactured out of stainless steel preventing corrosion caused by the stain removing chemicals. The vacuum feature is leg operated making it easier for the operator. Additional features include: Built-in boiler Two cold spotting guns standard with the third gun being optional Hot air/steam gun comes standard Stainless Steel bucks with suction Leg operated for three operators Large SS basin with tray for garment storage Ample space for chemical storage in stainless steel cups

Nova Lint Remover

230 Per Piece

shell removing machine

Get Price Quote

fluff cleaning gun

Get Price Quote

Easy to handle and operate, our Fluff Cleaning Guns are in compliance with the highest standards of quality. Further, these Fluff Cleaning Guns are corrosion resistant, sturdy and have long functional life. For price quotes, stay assured to get what’s the best in market. Besides, we are known for delivering even the bulk orders within the allocated time. Based in Delhi (India), we are a preeminent Exporter and Supplier of Fluff Cleaning Gun.