201 Saw Ginning Machine

Get Price Quote

We Bajaj Steel Industries Limited, Nagpur take this opportunity to introduce ourselves as a company that has achieved global proportions in Cotton Ginning and Pressing technology

GSM Round Cutter Machine

Get Price Quote

1 Piece (MOQ)

Best Deals from Textile Processing Machinery

Yarn Drawing Machine

Get Price Quote

Backed by a well-established warehouse, we are able to store the products in a secured manner. Thus, we ensure complete security of the products from any kind of damage. We have ultra-modern packaging systems available to keep the products safe from physical factors that may damage the product to some extent. Thus, we only use qualitative packaging material.

Reel To Sheet Cutting Machine

205,000 Per Piece

1 Piece (MOQ)

GSM Round Cutter

Get Price Quote

1 Piece (MOQ)

The GMS Round cutter is used to determine GSM (Grams per square meter) of the fabric (Woven Non-woven or knitted) and paper, film, foam, carper and board. The main body of the Round Cutter is made of fine quality aluminum casting for lightweight and resilience. Specifications Main body is made of fine quality aluminum casting for light weight and resilience Diameter of sample cut is 113 mm Catch lock is provided for safety.

GSM Round Cutter

Get Price Quote

1 Piece (MOQ)

The GMS Round cutter is used to determine GSM (Grams per square meter) of the fabric (Woven Non-woven or knitted) and paper, film, foam, carper and board. The main body of the Round Cutter is made of fine quality aluminum casting for lightweight and resilience.Features : Main body is made of fine quality aluminum casting for light weight and resilience Diameter of sample cut is 113 mm Catch lock is provided for safety. Diamond shape cutting on bottom for proper grip to the fabric Machine is equipped with 4 nos. of replaceable German Blade Movement of Hand Wheel is ¼ round to cut a sample User friendly design Supplied with User manual

Nuovo Pignone Weaving Machine

Get Price Quote

The company is counted among the dependable Exporters and Suppliers of Nuovo Pignone Weaving Machines in Thane. The Nuovo Pignone Weaving Machines, offered by the company, are known for their efficiency and reliability. The quality Nuovo Pignone Weaving Machines are procured from the trusted sources. Details For Nuovo Pignone Weaving Machines 8 Looms Nuova Pignone model TP 422 Year - 1984/85 Nominal Working Height - 220 cm 8 colors and dobby Staubli 2232 20 healded frames and 4 feeders from Savi 2 cloth rollers 20 heddles 4000 lamelles 300 RPM

wire weaving machine

200,000 Per Piece

GSM Round Sample Cutter

5,000 Per Piece

1 Piece (MOQ)

Cone to Cone Sizing Machine

4,500,000 - 8,000,000 Per Set

1 Set (MOQ)

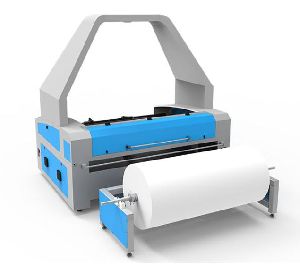

Textile Laser Engraving and Cutting Machine

Get Price Quote

1 piece (MOQ)

Draw Winder With Heat Setting

201,000 Per Piece

Specifications: Types of Winding - Precision b Conical Winding Mechanical Speed - up to 1200 m/min(Process Speed depending on process parameters ) Package shape - By Conical on Cylindrical Tube(Tape 3*.9*.12*) Traverse Length - 200 to 250 Take up Packages diameter - up to 300 Packages Weight - up to 6 kg Count Range/draw force - up to 4000 Dtex. up to 60 N draw Force. Coarser counts Possible Depending on feed Imperial and process Parameters Gauge - 450 mm Feeders/Positions - individuals Driven and Controlled/independently Driven And controlled . Electrical Power (Basic Power supply) - 440 V 50 Cycles, 1 phases Loadable Neutral Power line. Ground. Installed Power - 3.05 kw per position Installed Power For options - Rolling Device 15 W Position oiler Pump Motor 37 W Position Features: High efficiency Excellent performance Robust construction

Cotton Contamination Cleaner Machine

1,000,000 - 3,000,000 Per piece

1 Unit (MOQ)

optical+ultra sound+ultra violet optios • capacity(t/h) upto 1000 kg/hr • voltage(v/hz) 220v/50hz • mw power(kva) 1.5 • air consumption(cfm) 10 • camera nikon lens • color tri chromatic rgb (red,green.blue) • sensor toshiba brand ccd with 16200pixel • scanning speed 30 mhz • core (fpga + dsp) xilinx chip • power supply mean well brand power supply • display weintek brand display • fliter smc brand • valve 10 million times high-frequency ejectors • no.of cameras 16 (8 optical , 8 uv) • ultrasonic sensor 125 khz high speed transceiver • no.of sensors 24 • operating system the advanced embedded operating system • human interface color lcd touch screen for human interface • wirless internet connect support • remote control diagnosis, debugging and software upgrading • led source high luminance, low power consumption,100k hours • uv light source highly durable dc uv lights • no.of high accuracy speed ejector valves 24 • camera operation lines/sec 12000 times/sec • ejector max operating frequency 100hz+ • valve on/off response time within 5 - 6.5 ms • dimension(mm)(l*w*h*) 1474x1450x2322

Reel Cleaning Machine

185,000 Per Piece

1 Piece (MOQ)

Vibrating Screen Machine

300,000 Per Piece

Warper Machine

20 Per Piece

Fully Automatic Round Cotton Wick Making Machine

35,000 Per Piece

1 Piece (MOQ)

Vibrating Screen Machine

150,000 - 2,500,000 Per Piece

1 Piece (MOQ)

hthp yarn dyeing machine

Get Price Quote

1 piece (MOQ)

HT/HP VERTICAL YARN DYEING MACHINES. Introducing our HT/HP Vertical Yarn Dyeing Machine, a compact yet powerful solution for precision dyeing of yarn. Designed for efficiency and consistency, this machine features: - Very Low Liquor Ratio From 1:4 to 1:6. Turbo Main Pump With Multi Stage High Flow. Loading Up to 50 % Possible. Variable Frequency Drive ( VFD ) For Main Pump. PLC With TOUCH Screen For Complete Automation of Operations. Stainless Steel Electric Panel Encloser. Mechanical & Electronic Safety. Differential Pressure Gauge. Coil Type Heat Exchanger for Efficient and Fast Heat Transfer CAPACITY : 15 KGS TO 2000 KGS PER BATCH. HEATING MEDIA : STEAM / THERMAL FLUID. LIQUOR RATIO : 1:4 TO 1: 6. Machine is suitable for dyeing of all types of yarn like cotton, polyester, wool, acrylic & It's blends in form of cone bobbin, cheese, dye spring, hank, loose fiber, Muff & knitted. Hose capacities are from 15kgs/lot up to 2000kgs/lot. These machines are also suitable for dyeing narrow width tape, zipper tape & elastic tape. • Installation requires 2 floors (Ground & Platform). • Installation requires Hoist (crane) with factory shade height of minimum of 24ft to 36ft maximum depending upon machine capacity. • Material to liquor ratio from 1:4 to 1:6(*may vary from yarn to yarn). • Automation possible to automate all functions including interactive ones by means of PLC & TOUCH PANEL. • Complete Automatic Running of dyeing cycle through PLC with dual directional dye liquor flow, auto filling & drain.

Used Tsudakoma ZAX-9100 Air Jet Looms

1,000,000 Per Piece

We have Established Ourselves as Coveted Organization, Involved in the Business of Trading a Wide Range of Used Tsudakoma Airjet Loom. These Weaving Machines are Widely Used in Textile Industry for Weaving Various Kinds of Fabrics such as Cotton ,Polyester Viscose and other Blended Fabrics. Textile Weaving Machines Offered By Us are Developed and Designed By Japanese Tsudakoma Company Using High Grade Raw Material in Accordance with Industry Laid Norms and Guidelines. Furthermore, We Offer a Wide Range of Machines Under this Category Which Includestsudakoma Airjet9100 / Zax/ Za- 209i Cam / Dobby / Jacquard 190/210/220/360/390cm.

Vibrating Screen Machine

50,000 - 100,000 Per Piece

1 Piece (MOQ)

We are one of the leading Manufacturers, Suppliers, Distributors of this highly commendable range of Vibrating Screen Vibrating Screen has come out with a most advance design of screens for grading of fine, wet and difficult to screen materials. The screens works on the principle of gyratory motion. The unique features of this type of sieve is its high capacity using minimum space and less power. The screen has specially designed multi-directional vibration system which prevents blinding of sieves. The material to be screened is fed from the top and collected simultaneously from outlets of different decks. These screens can handle wide range of materials such as heavy, light, dry, wet, coarse or fine. The company manufactures various sizes to suit individual requirement in M S and S S construction.. Vibratory motion is the most effective method for screening. It causes 100% rotary motion and causes dispersion stirring & stratification of material to be sifted. Feed material constantly flows in Horizontal motion along a loop pattern on Vibro screen surface."EXCEL" Vibro screen provides optimum screening & assures maximum feed-rate & efficiency The vibrating screen is an important part of the incepting steps in any industry. The companies which require the processes or have the steps involved in the separation, sizing, and sorting the various materials and their parts out have the operations done with the good quality screens. Using the screens These screens are also called the vibrating sieves. The sieves we use regularly at home is in the ground level separation .i.e. small scale while the vibrating screen is the one which is used as a part of the initial processing of the raw materials in any industries. The cement industries, powder industries, companies that make spices, which produce fillers for food products etc. should have the correct mesh size to follow for the particles which are separated by these screens. Shape size make etc. These are availed in huge flat, basket shaped, cylindrical, and curved or even the irregular format of shape. The size would however vary from the products used to separate. The basic principle behind such separation is the size of the mesh and the gravitational force. The dimensions decide the shape and kind of products to be separated.These screens are highly durable and tough made from the metals that are hard enough for the usage and corrosion free too. To avoid spillages as well there are mechanisms provided in the screen feeders.

Semi Automatic Cotton Wick Making Machine

13,500 Per Piece

1 Piece (MOQ)

Coil Slitting Machine

Get Price Quote

The Coil Slitting Machine we offer is a complete solution to slit the coil in desired width. The Coil Slitting Machine is a perfect combination of precisely machined heavy duty fabricated terminal equipment. Project on turn-key basis can be executed with the help of Coil Slitting Machine to meet the exact requirements. The Coil Slitting Machine has a capacity up to 8mm thk x 1600 wide. Attributes : Heavy duty Capacity up to 8mm thk x 1600 wide Low maintenance Available at competitive prices

Tespa IPG T9 Swing Arm Gauge

120,000 - 135,000 Per piece

1 piece (MOQ)

Consisting of Electronic Controller with Digital of Least count 0.001mm having Three Control output for coarse feed, fine feed and to finish controls. The measuring head is a Swing Arm Type with LVDT Transducers including Inter Changeable Caliper for diameters from 7mm to 65mm OR 65mm to 125mm with Diamond contact points, with Dashpot Assembly for Mounting the measuring head to the machine

reeling machine

Get Price Quote

DETAILS : Reel machinery acts as pre-cleaner, fine cleaner and grader. Industrial Reel Machine is used to separate out impurities from the grains which are bigger or smaller than mainstream material size. Reel cleaning machinery is very versatile and it is used in several applications. Machinery can be of single sieve, double sieve or triple sieve in round shape. Machine serves to separate coarse impurities, such as straw particles, string, paper, pieces of wood, leaves and cobs etc and fine impurities such as sand, dust, broken seeds and few more. It is also used in grading of seeds so it is also called cleaning and grading machine. Robust in construction. Optimum quality raw material. Sieve replacement is easy and quick. Self-sieve cleaning mechanism.

Imported Round Card Cutter (upto 3inch)

4,500 Per piece

Imported Round Card Cutter Punch - ManualSize - 35/42/54/68/85mmPaper Type - PVCAction - Hand Operated+18% TAX EXTRA ON MACHINE

Ultrasonic Fabric Cutting machine

Get Price Quote

1 Piece (MOQ)

35Khz Ultrasonic Fabric Cutting MachineFeatures and Function Real time frequency automatic tracking display Welding modes: time, energy, and grounding. Amplitude division function Welding amplitude 10%-100% adjustable (1% accuracy) Amplitude compensation Mold impedance analysis + protection Overload protection Voltage protection (input) Transducer voltage protection 485 communication

Hydraulic Bangle Sizing Machine

Get Price Quote

Our Hydraulic Bangle Sizing Machine requires less maintenance and configured with pressure control valve for safety. We frequently keep a check on the storage space to ensure that it is well-maintained by the experts. We have installed the latest machines and leading technologies to save products from spoiling. Enlisted amidst the renowned Suppliers of Hydraulic Bangle Sizing Machine, we cater to varied demand of the customers in this sphere. Specification & Details : This new type of sizing machine is very compact and useful to Gold smith and imitation jewellery manufacturers. Special features of this machine is you can level bangle or ring with first stroke. You are getting perfect bangle or ring sized with the second stroke and with the third reverse stroke the bangle is removed automatically with bangle retrieving ring. Technical Data : Model - HBSM- S1 Machine power supply - 230v, 1Phase., 50Hz / 60Hz Machine Dimensions – 21”x 24” x 34” Machine Weight – 100 kg.

air jet mill

350,000 - 4,000,000 Per piece

1 piece (MOQ)

The Micronizer’s innovative design and fluid energy system enable numerous special-applica- tion possibilities for basic grinding, such as: Ceramic powders using wear-resistant ceramic liners Agricultural chemicals without attritional heat DN Pharma Micronizer meet a variety of material and output specifications. The typical feed size for Micronizer is 100 mesh or finer. The product size ranges from sub-micron to 44 microns. Capabilities range from 1/2 to 2000KG per hour. Micronizer may be operated using either compressed air, steam or inert gases.

Glass Mat Slitter

Get Price Quote

The slitting machine series (shaft or cylinders) are designed to cut rolls of different diameters, weight and length into strips, giving flexibility and efficiency to your roll storage. Roll-mat cutter adopts a triple-pole variable speed motor as its power source. The speed can vary according to different diameters of the rings and different cutting diameters. Different rotational speed can be set when linear velocity is kept unchanging. This roll-mat cutter can cut rolling braided fabrics such as continuous mat, combination mat and surfacing mat made from fiberglass or carbon glass. Fabricated form structural steel like, channel, angle or pipe Suitable for Mat Roll up to Ø 400 mm X 1600 mm Slitting width / Blade position adjustment by manual Mat Roll mounting spindle movement by suitable geared reduction drive & inverter drive for achieving required spindle speed Electric requirement: 0.75 kW.