thin film evaporator

Get Price Quote

We are one of the corrosion resistant Wiped Film Evaporators Manufacturers based in India. Wiped Film Evaporator is a Thin Film Evaporator and consists of a jacketed glass SS other corrosion resistant pipe section in which is rotating a corrosion resistant PTFE SS other corrosion resistant wiper system with suitable rows of blades supported by suitable bearings. Wiped Film Evaporators give a high wiping frequency and therefore, an optimum renewal speed of the boundary layer, which are pre-requisites for thorough mixing of the liquid film and for high evaporation rates. The Thin Film Evaporators are forced against the evaporator wall by centrifugal force, and this can be varied via the speed of rotation of the drive, depending on the viscosity of the liquid.

Agitated Thin Film Evaporator

800,000 Per Piece

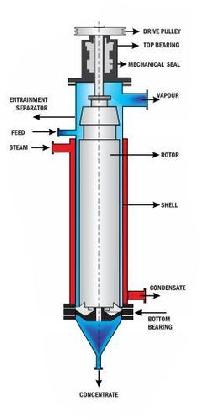

Thin Film Evaporator (TFE) is designed to continuously separate volatile compounds by applying a mechanically agitated thin film of feed material to a heated surface. The short residence time enables efficient and reliable processing of a large number of viscous, heat sensitive and high boiling point products.

Best Deals from Thin Film Evaporator

thin film evaporator

Get Price Quote

We are one of the corrosion resistant Wiped Film Evaporators Manufacturers based in India. Wiped Film Evaporator is a Thin Film Evaporator and consists of a jacketed glass SS other corrosion resistant pipe section in which is rotating a corrosion resistant PTFE SS other corrosion resistant wiper system with suitable rows of blades supported by suitable bearings. Wiped Film Evaporators give a high wiping frequency and therefore, an optimum renewal speed of the boundary layer, which are pre-requisites for thorough mixing of the liquid film and for high evaporation rates. The Thin Film Evaporators are forced against the evaporator wall by centrifugal force, and this can be varied via the speed of rotation of the drive, depending on the viscosity of the liquid. Function: The roller wiped film system guarantees a uniform, laminar mixing of the thin film on the entire evaporator surface. Due to overlapping of the rollers and wiping on the unheated areas, so-called “dead-zones” are avoided. At the same time, the liquid thin film on the rollers is continuously renewed. This results in a very low residence time of the evaporating feed on the evaporator surface. Build-up or caking of material on the evaporator surface and on the rollers, which might happen with other wiping systems, is completely avoided with the Ablaze designed roller wiped film system All contact Parts are Glass and PTFE. Designed to carry out distillation at high vacuum. Efficient condenser to condense all the vapors at high vacuum. All Flameproof Electricals and Instrumentation. Can be scaled up to 1 Sq. Mt2 Heat transfer area. Optional SCADA Operated system.

thin film evaporator

500,000 - 1,000,000 Per Piece

1 Piece (MOQ)

Agitated Thin Film Evaporator

Get Price Quote

1 Piece (MOQ)

Agitated Thin Film Evaporator is best suitable for heat sensitive products where product drying time and the drying temperature are very critical and well-acknowledged among the buyers for its qualitative features. Our Agitated Thin Film Evaporator is for drying, vacuum distilling, and many more. We are counted as one of the leading Manufacturers and Exporters of Agitated Thin Film Evaporators. Able Engineering‘s Agitated Thin film evaporators quickly separate volatile from less volatile components using indirect heat transfer and mechanical agitation of a flowing product film under controlled conditions. Either the vaporize component (distillate) or the concentrated component may be the product. Able Engineering provides turnkey solutions for Herbal extraction plants, Phytoextraction, and phytochemical plants.How Thin Film Evaporator WorksThe Product continuously fed into the Thin Film Evaporator above the heating jacket and spread onto the periphery of the distribution ring. The product then picked up by the rotor blades and immediately formed into a thin turbulent film on the heat transfer surface. The volatile components of the feedstock very quickly evaporated and flow counter-currently with reference to the feed, up towards the top of the evaporator to the rotating separator. Here, entrained droplets or foam knocked out of the vapor stream and return to the evaporation zone. The evaporated components then flow out of the evaporator into the condensation stage, column, or to another downstream process step.For special applications co-current vapor/product flow used in which a separation vessel fitted at the bottom of the evaporator below the rotor in place of the normal rotor mounted separator and the upper vapor outlet nozzle.Thin Film Evaporator Advantages Suitable to high vacuum distillation with very low residence time. Narrow spread Avoid product re-circulation and possible degradation Apt for viscous products Ideal for hazardous applications Thin Film Evaporator Applications Vacuum Distillation Drying Solvent Recovery The Concentration of bulk drugs, enzymes, juice, milk product etc.

Agitated Thin Film Evaporator

1,500,000 Per Piece

1 Piece (MOQ)

thin film evaporator

Get Price Quote

1 Piece(s) (MOQ)

To offer our purchasers top-notch range of products, we ensure only optimum grade supplies are utilized for their production. From traditional payment methods to modern ones, we are familiar with all of these payment methods. According to the suitability of patrons, we ensure the payment for an order is done conveniently. Features : Precision engineered Advanced technology Easy to maintaing

thin film evaporator

Get Price Quote

We are offering thin film evaporator. Tfde excels in distillation steps where products are heat sensitive, viscous, tend to foul heated surfaces, or are high temperature boiling. Thin film drying evaporators can be installed in a variety of configurations. Tfde with internal condensers can operate under high vacuum. Thin film drying evaporators without internal condensers are called top vapor outlet. Operate under high vacuum reduced operating temperature. major benefits include: *high vacuum operation *compact design *lower installed cost

thin film evaporator

Get Price Quote

We are one of the trusted companies in India, which is manufacturer and exporter of Thin Film Evaporator Manufacturer. The system we provide is based on latest technology, which is mechanically designed and tested by our engineers so that it can give the best of its performance. Our system is fully customized to meet our client’s requirement.Thin Film Evaporator made of glass for the gentle distillation of thermal sensitive products. Thin Film Evaporators are used in Chemical Laboratory &Industry for the production and processing of low-molecular as well as micro molecular substances. Because of the thermal sensitiveness of such products, this separation method is applicable.The medium which is to be distillate is exposed only for a very short time to the heating substance because of the film, which is created by the wipers, can evaporate very quickly. The residence time of the medium on the heating surface is a matter of seconds, thus essentially less than in a circulating evaporator. The glass construction of the evaporator permits all procedures to be exact visually made in the evaporating.

Agitated Thin Film Evaporator

500,000 Per Piece

Agitated Thin Film Evaporator

Get Price Quote

The typical Agitated Thin Film Evaporator consists of a tubular heat transfer area with an external heating jacket and a fast-revolving, inner rotor with flexible or rigid wiper elements. The driving speed is adapted to the product being handled, its particular specifications and task. Key Advantages : Good heat conductivity (k-value), even when working with highly viscous and contaminated products Minimal thermal stress, thanks to low operating capacity, therefore a short dwell time (10-20 seconds of mean dwell time) No dead zone, therefore overheating prevented and perpetual high product quality guaranteed Continuous mechanical cleaning of the heating surface prevents incrustations High evaporation rates, due to highly turbulent film and large difference in temperature Gentle evaporation, due to short residence times, rapid conveyance in the heated zone and the constant product film renewal, happens often Combined with suppressed boiling points due to operation under vacuum Reduced need for maintenance because of sophisticated bearings and shaft sealing parts Shorter downtime and assembly time for maintenance and inspection No corrosion as outside surface is usually made of stainless steel Evaporation in one pass, no circulation Small film thickness, no hydrostatic height High turndown ratio and high flexibility for variation in requirements Low operating pressure down to 1 micron to reduced boiling temperature Single step drying because of unique designed combination of vertical and horizontal dryers Effective evaporation of concentrated slurries, heat sensitive products, viscous and fouling fluids up to 99% in a single pass Simple installation as the equipment is supplied skid mounted with all inter connecting piping, condensers and vacuum system Applications To concentrate highly viscous products, polluted liquids, salt solutions, oils, resins, etc As a sump evaporator for vacuum rectification columns Sludge drainage

thin film evaporator

Get Price Quote

Thin Film Evaporator Plant

1,400,000 Per Units

thin film evaporator

Get Price Quote

We manufacture and supply wiped film evaporators / agitated Thin Film Evaporator.

Thin Film Evaporators

1,000,000 Per Set

Agitated Thin Film Evaporator

4,500,000 Per Units

1 Units (MOQ)

Thin-film Evaporator Design

Get Price Quote

Thin – film Evaporators are vertical, Mechanically Operated Continuous Film Evaporator designed for difficult concentration, extremely heat sensitive materials wherein the unit operations like Distillation, Evaporation and Stripping can be conducted. This technology gives the ability to remove volatile components from less volatile materials that are heat – sensitive, viscous, foaming, or contain solids. It offers short residence time, thin film formation by the centrifugal force of the rotating wiper system, the speed of which, can be adjusted to the viscosity of the product to be evaporated, which increase the evaporation efficiency. This is possible by the creation of the uniform film on the smooth heated surface of the glass body. Of late, the demand for test and pilot plants for gentle distillation has considerably increased in Fine Chemicals, Pharmaceuticals, Foods & Beverages industry. The Constantly rising number of new products and rising world market price of raw materials are responsible for this demand. Salient Features: Maximum Evaporation in Single Pass The Roller – wiper system (fully corrosion resistant construction) makes possible to attain a homogenous mass of liquid mixture and high wiping speed maximise evaporation efficiency. Minimal to no degradation of thermally unstable materials. The Capability of Handling High Viscosities. High surface to volume ratio Higher Heat Flux due to uniform film formation No dry spots and no fouling. Easy to clean, install and maintain Thin- Film – Evaporators are available in DN-80 X 0.15m² to DN-150 X 0.5m² Evaporation surface Area. Thin – Film – Evaporators can be run up to 200°C Product side and 230°C Jacket Side. Thin – Film- Evaporators can be run under Jacket Pressure of 2.0 bar (g) and evaporator can be operated at the vacuum of 5mm Hg to 0.005mm Hg. All wetted – parts that make contact with liquids or gases are made from high precision Borosilicate Glass Tube and PTFE

Agitated Thin Film Evaporator

Get Price Quote

Agitated Thin Film Evaporator

4,500,000 Per Unit

1 Unit (MOQ)

Agitated Thin Film Evaporator

Get Price Quote