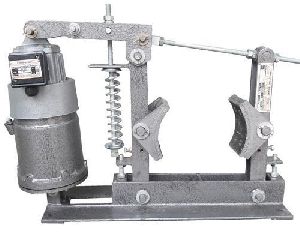

MDT 500-46 Mill Duty Thruster Brakes

36,550 Per Piece

5 Piece (MOQ)

hydraulic thruster brake

7,000 - 40,000 Per Piece

Best Deals from Thrustor Brake

Thruster Brake

Get Price Quote

50 Piece (MOQ)

stern thruster

Get Price Quote

100 Piece (MOQ)

Thruster Brakes

13,000 - 90,000 Per pieces

10 Piece (MOQ)

Plicare Material Handling PVT LTD takes immense pride in being a leading Thruster Brakes exporter, offering high-quality braking solutions for a wide range of industrial applications. Our thruster brakes are designed to provide reliable and efficient braking performance, ensuring safety and control in critical operations. Our thruster brakes undergo rigorous testing and quality checks to ensure optimal performance, durability, and compliance with international regulations. We offer a comprehensive range of thruster brakes with varying capacities to cater to different load requirements. With our Thruster Brakes, you can enhance the safety and efficiency of your operations, minimize downtime, and protect your valuable assets. Contact us today to explore our range of high-quality thruster brakes and experience the reliability and excellence that sets us apart as a leading exporter in the industry.

Thruster Brake

Get Price Quote

100 Piece (MOQ)

Hydraulic Thrustor Brake

9,500 Per Piece

50 Piece (MOQ)

Electro Hydraulic Thruster

3,500 - 18,000 Per Set

1 Set (MOQ)

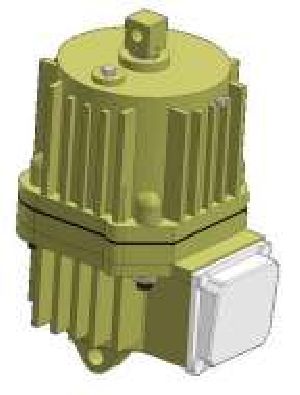

Thruster is an electro hydraulic device, designed to exert acontast force to any mechanism to be operated. The Thruster work on a principle of hydraulics. On supply of eectric power, motor driven centrifugal impeller draws the oil from the low pressure end of the chember to the high oressure upper end. The piston mounted on the same shaft moves to the upper end with full thrust, till its movement is stopped by the stopper shoulder at the end of the stroke. Pressure build up stops when power is discontinued. Radialblade design of the impeller enables it to rotate both in clockwise and anticlockwise direction. Therefore power supply to star connection can be in any R-Y-B phase sequence.Special Features : Packaged self contained unit-No external piping and accessories required. Self aligned movement Rated force available for the entire stroke Compatible for use with any exiting or new system. Low power consumption Moving parts being immersed in oil, No frictional losses. Minimum maintenance. Thruster Set 520 :A compact 90 watt, 415 volts, 50 cycles, 3 phase Electric motor is directly mounted on the top of a piston. The piston is housed in the C.I. Tank filled with fluid. The piston moves the fluid from low pressure are to high pressure area. The specially designed impeller which is mounted on the motor shaft produces required fluid pressure.Thruster : ST 535 tost 13300 This range of two thrust rods and a common piston. The motor is mounted on the top cover of the tank. A separator plate divides the tank in two partitions-low pressure side and high pressure side. The spacer bushes control the thruster. The models are suitable for large capacity, Higher motor ratings and larger thruster forces.Maintenance :The thruster is designed for long trouble free service and needs no maintenance. The motor bearings are adequately sized and windings are designed to meet the sudden jerks and shocks. Normal maintenance like topping of the oil levels replacement of damaged worn out oil seal and gaskets is required. The terminal box must be cleaned periodically.

HYDRAULIC THRUSTER DISC BRAKES

Get Price Quote

Hydraulic Thruster Brakes: Our products are used extensively in the Mining, Ports, Steel and Power Generation industries on Conveyor drives, Stackers, Reclaimers, Ship Loaders, Ship-to-Shore, overhead and Gantry Cranes to name a few�

electro hydraulic thrustor brake

Get Price Quote

10 Piece (MOQ)

Electro Hydraulic Thruster Brake

Get Price Quote

Electro Hydraulic Thrustor Brakes

Get Price Quote

We are offering electro hydraulic thrustor brakes. Electro hydraulic thrustor: thruster brake is a device used to retard the speed of moving machinery and to stop it accurately to the desired position. The braking force is applied to the brake shoes by a pre-stressed comprising spring. The shoes press on the rotating brake drum retarding its speed and finally stop it. The releasing of the.

ELOPHY Thrusters

Get Price Quote

Product Code : ELOPHY-1 Short Decription Thrust Capasity:- 23 Kg; Stroke Length: 50mm Availability : In stock

Hydraulic Thrusters

Get Price Quote

Electro Hydraulic Thrusters are the hugely acknowledged product of our offered range. We are pleased with the response, which clients have shown in our supplied Electro Hydraulic Thrusters. Provided with high-capacity drum, these Electro Hydraulic Thrusters are catered through us in worldwide markets.

Thrustor Brake

Get Price Quote

Buy high-quality Thrustor Brake Assembly at best prices from us! The Thrustor Brake, in which we deal, is noted for its robustness and dimensional accuracy. It is known as the ace brakes for various applications. Its design and performance are ensured to comply with the quality standards. Such efficiency has placed us in the group of acknowledged Manufacturers and Suppliers of Thrustor Brake in Mumbai, Maharashtra.

hydraulic thruster

Get Price Quote

hydraulic thruster brake

8,000 Per Units

Thruster Brakes

Get Price Quote

Thruster brakes, Interlocking shoes clearance balancing device and shoe auto-aligning device ( patented technology ), constantly equalize the clearance of brake shoes on both sides and no need to adjust, thus completely avoid one side of brake lining sticking to brake disc.

Flameproof Thruster Brake

Get Price Quote

"Suni" Brand FLP/WP Thrustor BrakeTesting As per IS/IEC 60079-1:2014 , IS/IEC 60079-0:2011 & Dust ignition protection as per IS/IEC 60079-31:2008 & Weatherprrof Testing as perIS/IEC 60529:2001 for IP 66 ,Used in Zone 21-22 also Zone 1 - 2 for gas goup-IIA,IIB & IIC atmospheres "Suni" Brand Flameproof (FLP/WP) thrustor/Thruster is electro hydraulic device to apply pressure or actuate lever mechanism of brake arrangement. An FLP/WP Electro-hydraulic thrustor is an independent mechanism which requires neither clutches nor external piping. The FLP/WP thrustor cylinder accommodates a centrifugal pump and a piston with two push-rods extending outside through thrustor cover and transmitting effort to the brake The robust design Thrustor unit is compact and has long life and is easy to maintain. Main components used are of high quality cast iron and steel. The Thrustor is operated by an integral three phase squirrel cage motor. The device has the following advantages: Constant Pressure Gentle Application and release of brake without jerks and shocks. Larger number of switching-in operations per hour (up to 720). The rated stroke of each type of thrustor can be changed, retaining the same attractive force, by means of sleeves fitted on the rods (inside the body) (this arrangement is possible with models from ST 535 and above) In cranes / hoisting machinery, brakes are intended for controlling the speed of load, lowering or for holding the suspended load at rest Suni Brand Flameproof (FLP/WP) Mill duty Thrustor/Thruster Brakes are suitable for 415/440 Volts, 3 Phase A.C. supply for a wide range of drum sizes, from 100mm to 400 mm dia. Higher sizes can also be supplied against specific requirements. The brake is applied by the tension of the compressed springs mounted vertically between the thrustor and brake lever. The thrustor rods are connected with the brake by means.

Thruster Hydraulic Brake

10,000 - 50,000 Per Nos