Double Phase Thyristor Power Controllers

Get Price Quote

We are engaged in manufacturing, exporting & supplying of Double Phase Thyristor Power Controllers from Delhi, India. Our Thyristor Power Controllers is known for their durability, power consumption, and smooth operation. Buyers can rely on us for delivering small or bulk orders of Double Phase Thyristor Power Controllers within the postulated time. Features : Soft start – bake out feature prevents moisture at start up Current Limit , Phase Loss Trip, Over temperature Trip Microprocessor Digital Programmable Thyristor Power Controller with Percentage Display. Program : Setting of Current Limit, Soft start etc by front keys Dydac Controls Thyristor SCR Power Controllers | A sample of some typical applications : Plastic Extruders , Plastic Injection Moulding machines Thermoforming, textiles, industrial furnaces and ovens, extruders, kilns, chemical process heating, fast water heat. Paper and pulp drying, packaging machines, pharmaceutical processes, infrared ovens and dryers. High-temperature ovens and furnaces, kilns, glass, ceramics & high-temperature alloys. Large tank heating and mechanical relay replacement. High-speed paper and ink dryers, high temperature IR heating, high temperature materials processing. Primary of transformer-coupled loads. Phase angle proportional control. No temperature or power cycling I2T Rectifier fuses standard Isolated SCR's Integrated thermal/mechanical design saves panel space Voltage protection - MOV capacitance 10 to 400 Ampere current ratings. Other Ratings Over 400 Amps Possible. Easy to install, test, service The Dydac Thyristor Power Controller is a heavy duty, fully Digital two phase power control unit for controlling the voltage applied to loads such as heating elements, thus, allowing temperature control while eliminating contactor switching and over/under heating. The first in a series of Digital ( SCR ) Power Controllers incorporating protection functions. Built in switching methods are : Phase Control Firing Zero Crossing Firing Advantages at a glance : Fully digital Thyristor Analog Thyristor Phase Control and Zero Crossing Current: 15 – 300 A (consult us when higher ratings are needed) Voltage: 230- 500 V 50/60Hz Cooling Method: Natural or Forced air Ambient. Temp: 0 - 50°C Continuous Duty Two controlled phases C.T.'s Input, 4-20mA or 0-20mA, 0-10VDC Digital display Control Input: Analog (4-20mA/0-20mA/1-5V/0-5V) Indicating of analog signal. Automatic Output-limit cognition of external volume or internal limit setting. Various alarm mode(over current, line failed, over temperature, load unbalance) Fault alarm output / Run output Programmable soft start. True RMS current display Auto/Manual mode operation is possible. Over current trip Output Current Limit Function Built-in watch timer Heat-sink temperature Load unbalanced level is programmable Compact size LEDs : Over Current Over Temperature Alarm Trip Protection functions : Under & Over current Shorted SCR Heat sink over temperature Trip & Alarm Internal failure The SCR control can deliver electrical power to heaters in several ways: phase angle fired, zero voltage switched and on/off control. Double Phase: Watts÷ Volts= Amps - Example: 18,000W ÷ 440V = 40.9 A Amps X Volts= Watts - Example: 40.9Ax 480V = 18,000W Amps X Volts X 1.73 = Watts - Example: 60A x 480V x 1.73 = 49,824W, Example: 18,000W ÷ 240V = 75A Specification : Ratings : Double Phase – 25 , 34, 59, 70, 90, 150, 200 , 250, 300 Amperes Range : 15 A - 400 A , 220-1200V Connection types : Double Phase Power Calculation : When selecting the correct sized SCR power controller, rate the SCR for at least 110% of the heater load. Heaters and power lines have tolerances that can swing on any given day or location.

Thyristor Power Controllers

6,000 - 100,000 Per Piece

1 Piece(s) (MOQ)

“S. S. Controls” brings in superior quality Thyristor Power Controllers in the international market. The Microprocessor Based Thyristor Power Controllers made available by us, have single, two and three phase A.C. SCR power controllers for resistive inductive loads. These Thyristor Power Controllers can also be availed in analog version. They find numerous applications in A. C. power control of inductive and resistive loads of any capacity. Apart from the above fact, the company is identified as one of the chief Thyristorised Power Controllers Manufacturers in India. Thyristor (SCR) Power Controllers / Power Control Circuits. Single / Three Phase / Two Phase A.C. SCR Power Controllers for Resistive Inductive Loads. Microcontroller / Analog Versions available. Applications: A.C.Power Control of Inductive / Resistive Loads of any Capacity. Resistance Metal Gathering / Heating Machines. Thyristor Control Cards / Circuits Single Phase / Two hase Thyristor control Cards for Resistive / inductive Loads. Microcontroller (Digital) / Analog version available.

Best Deals from Thyristor Power Controllers

Autonics Thyristor Power Controller

Get Price Quote

1 Piece (MOQ)

Thyristor Power Controller

Get Price Quote

We supply Thyristor Power Controllers to all our clients. This is an important electronic device that is employed in numerous electronic circuits. We supply these to our loyal clients who regularly purchase from us in bulk and marginal sized quantities. Our delivery services are reputed to be prompt and supply the goods securely packed without any kind of loss in quality or quantity.

Thyristor Power Controller

5,000 Per Piece

Thyristor Based Controlled Battery Charger

Get Price Quote

1 Piece (MOQ)

These chargers are quite versatile in nature. They are exceedingly straightforward and convenient to use. With these chargers, you can remotely keep a check on the health of the rectifier as well as battery. These types of chargers have the capacity to digitise the output or input process. They can easily facilitate an effective communication system.

Thyristor Power Controller

Get Price Quote

Acquiring our premium and high-grade range of product is hassle free as our organization is located in Pune(India), which is easily accessible by road, rail, and air. As soon as the product is packed, we ensure that it reaches the customer in the dedicated time slot and for that we have well maintained shipping facilities available. Features and benefits : More accurate temperature control. Improved heater life. Least amount of stres on heater elements Isolated control section Over Current Tripping Very low & easy for manitanance Also Suitable for Inductive loads. Available single phase units upto 5 KW & Three phase units upto 200 KW. High sensitivity Over current limit Single phasing protection Semiconductor Fuses Soft start Regulation Through Auto/ Manual Mode. Over Temperature protection by Heatsink Applications : For fast heater switching To switch higher amperage electric heater To control variable resistance heaters To control transformer coupled resistance heaters In high- Speed paper and link Dryer, high temperature IR heating, high temperature materials processing High temperataure ovens and furnace, kilns, glass, ceramics & high temperature alloys. More About The product range includes Single phase controllers as well as Three phase controllers. Though products are available in standard specifications, we also offer customized product as per customer's requirement and specifications.

Thyristor Controlled Reactor

Get Price Quote

1 Set(s) (MOQ)

Thyristor Controlled Reactors are major components of an SVC system. The power semi-conductors are used in an SVC scheme to generate harmonics, and need to be eliminated by harmonic filters. Therefore in an SVC system harmonic filter, Thyristor Controlled Reactors are employed as well. The reactive power consumption of our Thyristor Controlled Reactor can be continuously controlled by thyristor valves. These Thyristor Controlled Reactors are commonly used in combination with switched shunt capacitors to provide variable reactive power as required. To limit the inrush current of the capacitors, series connected damping reactors are inserted ahead of the capacitor bank of the Thyristor Controlled Reactor. Highlights Variable reactive power Limited inrush current of the capacitors Controlled reactive power consumption Variable reactive power

Autonics Thyristor Power Controller

102,000 Per

Thyristor Power Controllers

Get Price Quote

Thyristor Power Controller

Get Price Quote

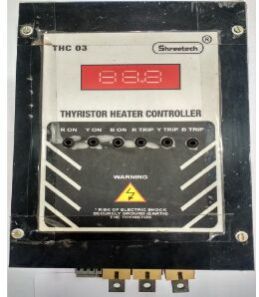

Features » Soft-Start» O/P Limit» Over Temp.Trip» Over Current TripSpecifications:

Zero Crossover Thyristor Firing Cards

Get Price Quote

These are very compact, sealed solid state cards with no moving parts, particularly suitable for high power switching of Capacitor Banks. Each Card can fire two separate Thyristor-Thyristor Module, with common control, without any need of external power source since the driver draws power from the mains 440Vac supply. Switching is silent, instant, does not cause any arcing and is unaffected by the number of switching operations, vibrations and corrosive atmosphere. The control input is optically isolated from the mains AC Power Switching Circuit. One Card is used per stage of APFC Control Panel. Input is a 3V-12VDC source in series with the APFC Controller Stage control output. A Single source can drive and control all the stages.

Thyristor Power Controller

Get Price Quote

Thyristor - CD3000M 2PH 15A to 700A DC Logic/Linear, ZC/BF 24V to 600VAC Supply, DC Logic, 4-20mA, 0-10V DC linear or 10K potentiometer inputs. CD3000M-2PH is a digital and universal Thyristor unit fully configurable via serial communication port. A fully digital and universal Thyristor, configurable via RS485 serial communication port or dedicated configuration port for all inputs, firing & performance parameters. Configuration software available as a download at no cost. Overview: Two leg switching of three wire star or delta resistive loads Suitable for loads up to 700A Microprocessor based electonic circuit fully isolated from power Universal input signal with automatic zero/span calibration Universal firing, customer configurable via serial port for zero crossing (ZC) and burst firing (BF) modes RS485 comms, MODBUS protocol included as standard Heater Break circuit microprocessor based to diagnose load failure and short circuit on Thyristors as option IP20 Protection

Industrial Thyristor Power Controller

Get Price Quote

We are offering industrial thyristor power controller. Specifications: digital 3 phase heater controller input -440v with nut .+- 10%, 50 hz output- 0 – 95% input control- 4-20 ma. Signal by external process. 0-10 v. Dc signal by external process. controller details- out put voltage proportional to input control signal by phase angle control of thyristors. indications - a) power on adjustment- a) voltage setting protections- a) dvdt protection by rc snubber construction- open execution module suitable to mount in side the panel

Thyristor Power Controllers

Get Price Quote

Thyristor units are fast and accurate power controllers which control electric currents using semiconductor devices called thyristors.

Thyristor Power Controllers

Get Price Quote

With wide and rich industrial experience, we are able to offer Thyristor Power Controller that includes Single, Two and Three Phase Heater Power Controller. We monitor the quality control process with utmost care to deliver defect free products to our clients spread all over the world. The well known features are reliability, robustness and efficiency. These heater power controllers are installed in huge industries to obtain in proved productivity and efficiency. These controllers have a wider acceptability for its extreme performance rate. Specifications: Available Ratings: 3 KW single phase to 300 KW three phase Available configuration: Single phase, two phase, three phase (3 or 4 wire star and 6 wire data) Control action / Control signal: Phase angle control (self synchronized) (4-20)mA/(0-5)VDC/(0-10)VDC/potentiometer (control signal available from PID temperature controllers Output: Suitable triggering pulses to fire back-to-back connected SCRS. Smooth control: Adjustable ramp up and ramp down time for soft increase and decrease of output voltage Current control: Using current limit and trip setting on card. (LTC-13) Settings: For adjusting voltage and current per phase Load Type: Suitable for both resistive and inductive/transformer load (15 A to 300 A @ 110/230/415 VAC) Availability: In the form of 1, 2 & 3 phase triggering cards, complete thyristor power pack or ready to use control panel with suitable PID pr program controller. Triggering cards are also suitable for 1 & 3 phase rectifiers.

Thyristor Power Controllers

3,000 Per Units

Thyristors Power Controllers

Get Price Quote

Modular Design Software Configurable Quick Start Easy Setup Advanced Configuration using Graphical Wiring Editor Predictive Load Management Flexible Communications

Thyristor Power Controllers

Get Price Quote

We are offring honeywell thyristor power controller.

Thyristor Power Controller

Get Price Quote