Tin Oil Packaging Machine

Get Price Quote

Ghee Tin Packing & Seaming Machine

Get Price Quote

Our Ghee Tin Packing & Seaming Machine is reckoned for its sturdy make. With the immense knowledge and experience, our company presents a comprehensive array of Ghee Tin Packing & Seaming Machine in the national market. We stock our product for wholesale distribution and supply as we have state-of-the-art storage facility along with the most advanced inventory management system and upgraded machines.

Best Deals from Tin Packing Machine

tin packing machine

Get Price Quote

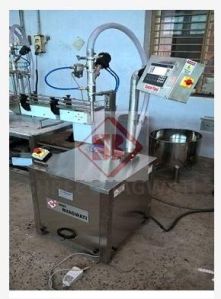

Containers like flat tins or bottles are loaded on turntable from where they are transferred onto a conveyor belt. They are then indexed into the filling station. No-Container-No-Fill device will stop dozing operation if containers are not in place. SS jacketed hopper with 2 kw heater and stirrer can be provided as an option to facilitate easy filling of highly viscous products. Filled containers are transported over conveyor for further operations and handling. Features: PLC Controlled machine with colour Touch Screen Can fill creams of various viscosity No –Container – No – Fill interlock Tail Cutting arrangement after dozing Easy change over from one size to another Fill quantity can be accurately adjusted Fill accuracy up to ±0.5%

Tin Cap Sealing Machine for oil packing

Get Price Quote

1 Piece(s) (MOQ)

These machines are corrosion resistant and require less maintenance.

tin packing machine

Get Price Quote

15Kg Oil tin filling machine is suitable to fill and seal 15kg Ltr oil tins of mustard oil,edible oil,refined oil, vegitable oil also lubricant and engine motor oil filling.Online filler with cap sealing unit, 15Kg Oil Filling also suitable to fill 5lit-20lit oil jars,containers filling.

tin packing machine

Get Price Quote

This Tin Filling Machine is designed and manufactured using excellent quality approved raw material and latest technology under the supervision of highly skilled professionals of our company. This filling machine consists of a weighing platform, electronic filling controller and pneumatically operated dual stage valve. These machines ensure accurate and hygienic filling. The speed of our Oil Tin Filling Machine differs as per the volume to be filled as the machine is equipped with bottom-up fill assembly and adjustable volume control. We manufacture these Liquid (Oil) Filling Machines using quality measures as per standards. These machines feature volumetric piston operated filling system that finds application in packing viscous and oils. It is available in various technical specifications as per the requirements of clients, we offer this High-Tech Oil Filling Machine at industry leading price.

tin packing machine

Get Price Quote

These machines offer different filling capacities ranging from 5 kg to 15 kg. The machines have a Mechanically operating system.

tin packing machine

Get Price Quote

these specification are:- Model name :Printing Tin Vacuum Packaging Machine Vacuum chamber size: 800 Width x 250 Length x 200 mm Height. Over all Size: 830 x 300 x 850 Construction: SS 304 MS. Lid: SS dome with Transparent Acrylic widow. Vacuum monitoring & control: German dial gauge, & vacuum sensor. Vacuum Pump: 40 cum. Electrical consumption: Maximum 3.5 KW only 3 Phase Packing cycle: 3 to 4 Cycles minute depending upon the product to vacuum packed.

tin packing machine

Get Price Quote

Packaging Solutions manufactures Printing ink tin container (canister) Vacuum packaging machine. We are the first to make this type of machine in India. This particular model is for three tin packaging. Though we can produce for any capacity and also inline packing. The size of vacuum chamber of this model is 850 wide x 200 High x 250 deep. It operates with only two parameter setting. Castor wheels are provided for easy movement of the machine. Packing cyle is 4 to 5 minute per batch. The working of the machine: Place the tins filled with the ink, lids placed on the tins in the vacuum chamber and close the chamber. After specified time lid of the Vacuumed chamber will open. And one can remove the vacuum packed tins.

tin packing machine

Get Price Quote

Cashew kernels are tend go stale very quickly. The kernels are filled into the tins by vibratory filling machine. The Tin Packing Machine fills 8 tins at a time with cycle time of about 12 to 15 minutes which works to about 400 kgshour. After tin filling Co2 is required only if the cashew r to remain in the tin for more than six months. c02 or n02 is abt 2 to 3 min. per tin so about 300 tins hour. Carbon dioxide is an inert gas and will not support life. Secondly, carbon dioxide is soluble in cashew oil and goes into solution as soon as the seals are made.

tin packing machine

Get Price Quote

Pop-can filler and capper machine is applicable for equal pressure filler and capper of carbonated drinks in beer and drink industry. It is a pop canned beer in the digestion and absorption of advanced foreign and domestic sealing machine on the basis of independent development of the can filling, sealing unit. Filling and sealing is the overall designed, power system by filling sealing system to ensure that both the absolute synchronization and coordination. It adopts the advanced machine, electrical equipment, and pneumatic control technology. It has the characteristics of filling reposefully, high speed, liquid level control, capping reliably, frequency conversion timing, less material loss. It can equip long-distance control system according to the customers request. It is the preferred equipment for the medium beer and beverage plant.

tin packing machine

Get Price Quote

The Semi Automatic Flowmatic PLC Base Machine is compact and highly efficient machine with elegant look. This multifunction multi featured machine meets the custom requirements of Bulk filling 15Kg Tin with no restriction of liquid characteristics. The machine has its own pumping system to fill the programmed liquid in Jars. The flow of liquid is measured and converted in to electronic signals being controlled by the PLC base circuit. No mechanical adjustments are required to set different fill volumes with different sizes of containers. i.e. No change part is required.

cashew tin packing machine

Get Price Quote

We are counted among the renowned firms in this domain, engrossed in offering the premium quality Automatic Cashew Kernel Packing Machine. The provided machine is broadly used packaging of cashew in required quantity options. Our brilliant professionals manufacture this machine as per set international quality standards using the finest quality components and state of the art techniques. Moreover, our valuable clients can avail this Automatic Cashew Kernel Packing Machine from us at the most competitive prices. Features: Easy to operate Longer service life Excellent performance High functionality Specification: Capacity : 50-70 packs/h Total power: 8Hp Pressure : 2bar Dimension: 10000mm W: 2000mm H: 2000mm Weight: 700 Kg

tin packaging machine

Get Price Quote

tin packaging machine

tin packing machine

Get Price Quote

tin packing machine

tin packing machine

Get Price Quote

tin packing machine, Candy Wrapping Machine, weigh filler

tin packing machine

Get Price Quote

tin packing machine

tin packing machine

Get Price Quote

tin packing machine, Flour Packing Machine, making machine

Tin Oil Packaging Machine

Get Price Quote

Tin Oil Packaging Machine, Industrial Packing Conveyor, Slat Conveyor