tool design service

Get Price Quote

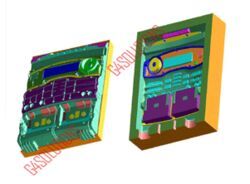

Our Tool Design Service specializes in creating precision tools and fixtures for various industries. Leveraging advanced design software and engineering expertise, we develop customized tools that optimize manufacturing processes and enhance productivity. From concept to manufacturing, we focus on precision, functionality, and efficiency in designing jigs, molds, dies, and fixtures. Our service ensures meticulous attention to detail, streamlining production operations and delivering high-quality, bespoke tools tailored to meet specific industry requirements.

Tool Design & Fabrication Services

Get Price Quote

Empower your manufacturing processes with our tool design and fabrication services. Our skilled team combines innovative design expertise with cutting-edge fabrication techniques to create custom tools tailored to your specific needs. From concept to completion, we ensure precision and functionality in every detail, optimizing performance and efficiency. Whether you require molds, dies, jigs, or fixtures, we deliver high-quality solutions that enhance your production capabilities. Partner with us to unlock new levels of productivity, reliability, and competitiveness in your operations.

Looking for Tool Design Service Providers

Press Tool Design & Development

1 - 1 Per kg

If you are in search of a reliable organization that is engaged in offering efficient press tool design & development services, then contact us. We are located in Chennai (Tamil Nadu, India) and offering outstanding designing and development services to the clients at very reasonable charges. Our highly efficient engineers are engaged in designing and developing the press tools according to the specifications provided by the clients by using advanced machines and quality raw materials.

tool designing services

Get Price Quote

Sree Varahhas team is well versed with Tool Design for various products. The team has worked with experts in different fields of tool design such as: . Forging Dies . Die Casting Dies . Plastic Moulds . Foundry Pattern Equipment . Sheet Metal Dies . Jigs Fixtures

Press Tools Design And Manufacturing Services

Get Price Quote

Press tools are used in hydraulic, pneumatic, and mechanical presses and used to produce sheet metal components. If you seek dependable assistance for tools design and manufacturing needs, then look no further. Operating from Pune (Maharashtra, India), we are providing press tools design and manufacturing services as per the individual’s functional requirements and needs. So, get associated with us and avail the benefits of simplified solutions that are cost-effective too. We provide error proof PRESS Tool manufacturing design precision is our ultimate motive for press too. We provide error proof Presstool manufacturing. Precision is our ultimate motive for presstools.

Design Engineering Tool

1,000 - 10,000 Per Unit

G4 SL TOOLKIT is now “CITIUSKBE TOOL KIT” which is a Flag ship product of SREE VARAHHAS TECHNOLOGIES. WHAT IS CITIUSKBE TOOL KIT? Citius Solutions has developed CITIUSKBE TOOL KIT as a ‘Plug-in’ for NX CAD software, with a view to help Designers, Managers and Entire Organizations extract more out of their NX Software. It is developed with ‘Configurability’ as its USP, to enable organizations to define and incorporate their own standards into this tool very easily, without any programming knowledge, which will make the implementation of this toolkit very fast and effective. * It is a Plug-In for NX CAD Software

SPM Machining Tools Designing Services

10,000 - 500,000 Per 1 set

As per customer need we will design machine and can train you as a expert as shwon images 4 legs rotary as per customer request

press tool design services

Get Price Quote

Consider our name if seeking expert level press tool design services. Operational from Karnataka, India, we are actively involved in serving one-stop solutions to the press tool industry. Ours is a team of professionals and designers who work in coordination with each other and produce 3D press tool designs depending on clients’ business requirements. All you need to provide is your requirements related to dimension, grade, design specifications, etc.; we will manage the rest.

Press Tool Die Designing Services

Get Price Quote

Details : Process Plan, Concept, Design, Assly to Drafting and detailing with GD & T Draw and Forming Dies Trim, Blank & Pierce Dies Progressive, Compound and combination Dies

Press Tool Design

Get Price Quote

We manufacture a wide array of press tools that are widelyused in the automobile industry for dieing sheet metal components and aremanufactured from high quality superior quality ferrous and non-ferrousmaterial that provide sturdy construction. Offering assured performance andefficiency, these dies and tools are competitively priced.

tool design

Get Price Quote

hs engineering services offers solutions and services to the mold & die industry as well. we can design a complete mold including the mold base and all accessories for the client. we have relevant expertise in the mold industry and apply that to create molds as per the client’s requirements.

tool design

Get Price Quote

We offer complete Tool Engineering service for Sheet Metal, Plastic, Die Casting, Forging and Automation products. We always starve hard to meet customer stated and implied need for tool engineering services. We do design and develop the tools according to customer requirements. The word “tooling” refers to the hardware necessary to produce a particular product. A considerable amount of tooling is the result of work performed by the tool designer and tool manufacturer. Tooling consists of a vast array of cutting devices, jigs, fixtures, dies, gauges, etc. used in normal production. The type of production will determine to a large extent the type of tooling. The most common classification of types of tooling is as follows: Cutting tools, such as drills, reamers, milling cutters, broaches, and taps Jigs and fixtures of guiding the tool and holding the work piece Gauges and measuring instruments Sheet-metal press working dies for all types of sheet-metal fabrication Dies for plastic molding, die casting, permanent molding, and investment casting Forging dies for hot and cold forging, upsetting, extrusion and cold finishing. Tool Design is a specialized phase of tool engineering. Tool-design functions are performed by a tool-design specialist who devotes his entire working time to tool design. Tool Designer uses the latest CAD/CAM/CAE tools for design and analysis of tools before the design is released for manufacturing thus it helps in cost cutting and improve the quality of tools. Our tool designer is commonly a specialist in one or perhaps two of the above types of tooling. For example, a designer of injection molds for plastics usually has little to do with the design of metal-cutting tools. On the other hand, a designer of cutting tools should be knowledgeable in jig and fixture design because of the close relationship between cutting tools and jigs and fixtures. Our basic task during the tool design project is to provide drawings of a tool or set of tools to produce the work piece. We are provided with a blueprint of the work piece to be manufactured, the name and specifications of the machine to produce the work piece, and the number of work pieces required. Our Tool design and manufacturing are based on the quantity of parts to be produced and are made as economically as possible for the required service. Our Tools are made as easy and safe to operate; it should also look practical and attractive, but it certainly should not have unnecessary elaborate trimmings or needless complexity. The latter point is very important, since even experienced designers sometimes let their enthusiasm for fine mechanisms lead them to develop excellent tools that are not practical from the standpoint of cost. Of course, striving to obtain economy may be overdone, and unsatisfactory tools produced. It is a question of good judgment based on experience. In order to complete our task as tool designer we produce a complete set of drawings showing an assembly drawing, one or more subassemblies, if the design is complex, a detail drawing of each part, a complete list of parts needed to make the tool. These are handed to the toolmakers, whose task it is to make the tools.

tool design service

Get Price Quote

tool design service, Hardware Tools, Cutting Tools

tool design service

Get Price Quote

We offer highly advanced tool designed services in the industry. The company is well supported with technical expertise and market competence to offer Tool Designing Services keeping the end vision of the valued clients in the market. Besides, we are acknowledged as one of the most reputed sources of quality tool design services in India.

tool design services

Get Price Quote

We are providing Tool Design Services

tool designing services

Get Price Quote

Nikita CAD/ CAM Solutions is a premier service provider company, instrumental in providing told designing services to the clients in and around New Delhi, India. Active in this trade since 2004, we are well supported with technical expertise and industrious workforce that goes the extra mile to achieve complete clients’ credibility. Over the years, we have earned accolades for rendering time-bound and precision designing solutions. Our service charges are reasonable; clients can approach us anytime for further discussion.

Machining Tools Designing Services

Get Price Quote

Machining Tools Designing Services, CNC Machining Services

Press Tool Designing Service

Get Price Quote

We are into design & manufacturing of press tools. We also provide design solutions for all types of press tools.

tool designing

Get Price Quote

tool designing, SPM Design, jig and jig fixture