Three Connection FIG Pump

Get Price Quote

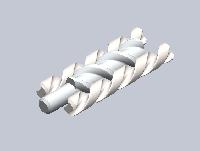

triple screw pumps

45,680 Per

1 Piece(s) (MOQ)

Best Deals from Triple Screw Pumps

Triple Screw Pump

Get Price Quote

We are offering triple screw pump. Material of construction casing: cast iron, cast steel, cast stainless steel liner: cast iron, cast stainless steel screws: alloy steel, nitried steel & stainless steel salient features high reliability long service life negligible maintenance high efficiency self priming smooth pulsation free flow low noise and vibration high speed capability insensitive to viscosities high pressure capability fast, easy replacement of parts mounting configurations to fit any spaces limitation :-horizontal, vertical, close-coupled ,sump in � line construction enables simplified piping arrangement. Ansi or din flanges while in operation, the screws are in hydrodynamics balance on film lubrication and do not require any additional bearings. The one ball bearing often used is only for axial positioning of rotor and safer operation of mechanical seals. Small rotor dimensions enable the pump to be operated at high speeds directly coupled 3000 or 3600 rpm motors or other prime movers. Such unique design and features had demonstrated excellent reliability with pumps in operation continuously non- stop for decades together without replacement of any components or maintenance on clean fluids. Key features � benefits that reduce life cycle cost maximum reliability of system to increase revenue pumps delivers smooth flows with minimum pulsations hydraulically balanced screws lower maintenance costs by up to 50 % pumping elements contained in one cartridge assembly fast, easy replacement of parts reduced overhaul turn around time no timing gears required and fewer wearable parts one or no bearings required and fewer wearable parts versatility to meet customer specification custom design fabricated pump and per api standards a choice of shaft seals for every application mounting configurations to fit in any space limitations: horizontal, vertical, close coupled, sump in � line construction enables simplified piping arrangements ansi or din flanges one pump size designed to offer flexibility in flow specifications capacity : from 1 to 400 m3hr pressure : up to 64 kgcm2 viscosity : 1-1, 00,000 centi stokes temperature: up to 300 .c user industries cement industry power stations petro chemical refineries oil depots ship building industry rayon, staple fibres steel industries fertilizer industries paper mills food processing industries breweries bitumen and asphalt industries these pumps are designed for handling clear viscous liquids and are suitable for different pressures upto 70 bars. The pumping elements comprise of a power screw and two idler screws, running in a close fitting insert. The idler screws serve to maintain the closed chambers that pump the liquid. Each screw is provided with a drum so that axial forces are hydraulically balanced. The shaft seal chamber is connected internally to the inlet and the seal is therefore always subjected to the inlet and the seal is therefore always subject to inlet pressure only. The inserts screws and balancing bushes together with bearing and seals for a replaceable cartridge that is located inside a casing. The pumps can be supplied in a variety of materials of construction and for various mounting arrangements.

3 HP Milk Pump

Get Price Quote

1 Piece (MOQ)

Three Screw Pump

Get Price Quote

The screw pump of series P 3S FP for a pump and up to 40 bar are three screw rotary positive displacement pump for handling lubricating fluids. They must not contain any abrasive particles nor chemically attack the pump materials. The pump are designed as flange mounted pump and via an intermidate lantern connected with the driving motor.

triple screw pumps

100,000 Per Piece

1 Piece (MOQ)

triple screw pumps

Get Price Quote

PDT Triple Screw Pumps

Get Price Quote

The PDT Triple Screw Pumps are available in vertical tank top mounted construction. These PDT Triple Screw Pumps can be provided with a return valve for allowing excess pressure to return to the tank. The PDT Triple Screw Pumps are used in Turbine Governing Systems. About PDT Triple Screw Pumps Carbon steel fabricated design casings are available.Suctions of vertically tank top mounted casings are completely immersed in liquids.

Triple Screw Pump

Get Price Quote

Marine Pumps Triple Screw Pumps

Get Price Quote

Three Screw Pump

Get Price Quote

Discharge : Upto 2800 lpm Differential Pressure : upto 220 bar Viscosity : 3 to 3750 cSt Typical Applications Machinery lubrication, hydraulic elevators, fuel oil transport and burner service, powering hydraulic machinery, polymer pumping, in refinery process for high temperature viscous products such as asphalt, vacuum tower bottoms and residualfuel oils.

triple screw pumps

Get Price Quote

Hydro Prokav offers Wide Variety of high performance Triple-Screw Pumps which are highly efficient in handling a wide range of liquids with varying viscosity at high pressures, for use in a variety of industrial and marine applications.

Hydroprokav triple screw pumps

Get Price Quote

Hydroprokav Progressive Cavity Screw Pumps are manufactured in a state of art plant spread over 25,000 square meters at Coimbatore. This modern plan comprises a full- fledged rubber with test labs, highly sophisticated quality control & R&D facility. Hydroprokav pumps are being satisfactory used by over 5000 customers for transferring more than 10,000 fluids & spans 40 countries worldwide. The unique 2.5 lengthy geometry of Hydroprokav pumps help bringing about many advantages like: Increased life of rotor & stator thereby reducing maintenance costs. Stability in pressure & flow over long periods ensuring optimum performance. Reduced thrust loads on universal joints & bearings thereby avoiding breakdowns. Reduction of vibration, turbulence, sheer rates & pulsation ensuring smooth performance. Hydropokav also offers Twin screw & Triple Screws pumps. This makes Hydroprokav pumps the ideal solution for transfer of viscous liquids & high pressure applications.

Three Spindle Screw Pump

Get Price Quote

"TUSHACO" - a leading name in the field of Positive Displacement Rotary pumps since 1968 introduced for the first time in India the concept of "Three Screw Pumps" already in 1970's. Foreseeing the growing demand for totally reliable fuel and lube oil pumps for Thermal and Hydel Power Plants, Fertilizer, Chemical and Steel Projects a beginning was made by importing critical components and building pumps locally. Over decades, thousands Three Screw pumps have been manufactured and delivered. Valuable experience gained and modern manufacturing and testing facilities established under joint collaboration from world-renowned German company. Today TUSHACO is undisputed leader not only in Three Screw pump technology but equally in the other types - namely Twin Screw, Single Screw/ Progressing Cavity - as well as the conventional types like Shuttle Block, Internal Gear, External Gear, Trochoidal and Vane types. This unique position, combined with years of Application Engineering expertise and knowledge of Process Engineering requirements offers direct benefit to customers by the right choice of the pump design selection for almost any given duty parameters. TUSHACO pumps are on the OEM list of practically all major plant and equipment manufacturers, consulting organizations and has met with approvals from third party inspection agencies - national and international. Reliable performance of thousands of TUSHACO Three Screw pumps in India and overseas - over decades is the silent testimonial of the hard and dedicated efforts behind this success. Working Principle TUSHACO Three Screw pumps employ just three screw elements - one power screw and two idler screws running in the three precision bores in the housing or liner. The screws are so profiled that they form a liquid tight seal between the thread. As the screws rotate, pockets/ cavities are formed where liquid gets trapped and conveyed from one end of the infinite stroke. This results in smooth, pulsation free flow with extremely low noise and vibration levels, almost impossible to be achieved by any other design of positive displacement or other types. The power rotor does not drive the idlers as commonly believed. The hydraulic forces acting on screw flanks turn the idlers torquelessly thus reducing the friction. The idlers simply roll over the root diameter of idler dia.reduce the unit pressure, centralize the power rotor and absorb the radial loads. A balance piston integrally machined on power rotor takes care of axial thrusts. While in operation, the screws are in hydrodynamic balance on film lubrication and do not require any additional bearings. The one ball bearing often used is only for axial positioning of rotor and safer operation of mechanical seals. Small rotor dimensions enable the pump to be operated at high speeds directly coupled 3000 or 3600 RPM motors or other prime movers. Such unique design and features has demonstrated excellent reliability with pumps in operation continuously non-stop for decades together without replacement of any components or maintenance on clean fluids.

Three Screw Pump

Get Price Quote

Delta Corporation group is the pioneer in the field of Positive Displacement Rotary pumps since 1968. They introduced for the first time in India the concept of "Three Screw Pumps" in 1970's. Foreseeing the growing demand for totally reliable fuel and lube oil pumps for Thermal and Hydel Power Plants, Fertilizer, Chemical and Steel Projects a beginning was made by importing critical components and building pumps locally. Over decades, thousands of Three Screw pumps have been manufactured and delivered. Valuable experience was gained and modern manufacturing and testing facilities established under guidance from world-renowned European companies. Over the years the market has grown considerably and the field of applications has become more diverse for these pumps, compelling innovations in the design and production of the pumps to answer the demands of the market. In line with the current requirements, Delta is proud to present to this mature market, reliable, low noise, low vibration and low cost three screw pumps produced as per the latest state of the art manufacturing practices. We have partnered with Settima Meccnaica s.r.l who are leading manufacturers of screw pumps in Europe since 1978. Settima has focus on low noise, low pulsation pumps which help increase the overall efficiency and life of the pumps Settima-Delta pumps are on the OEM list of major plant and equipment manufacturers, consulting organizations and has met with approvals from third party inspection agencies - national and international. Working Principle Settima-Delta Three Screw pumps employ just three screw elements - one power screw and two idler screws running in the three precision bores in the housing or liner. The screws are so profiled that they form a liquid tight seal between the thread. As the screws rotate, pockets/ cavities are formed where liquid gets trapped and conveyed from one end of the infinite stroke. This results in smooth, pulsation free flow with extremely low noise and vibration levels, almost impossible to be achieved by any other design of positive displacement or other types. The power rotor does not drive the idlers as commonly believed. The hydraulic forces acting on screw flanks turn the idlers torquelessly thus reducing the friction. The idlers simply roll over the root diameter of idler dia.reduce the unit pressure, centralize the power rotor and absorb the radial loads. A balance piston integrally machined on power rotor takes care of axial thrusts. While in operation, the screws are in hydrodynamic balance on film lubrication and do not require any additional bearings. The one ball bearing often used is only for axial positioning of rotor and safer operation of mechanical seals. Small rotor dimensions enable the pump to be operated at high speeds directly coupled 3000 or 3600 RPM motors or other prime movers. Such unique design and features has demonstrated excellent reliability with pumps in operation continuously non-stop for decades together without replacement of any components or maintenance on clean fluids. Salient Features High reliability High speed capability High speed capability Long service life Insensitive to viscosities Insensitive to viscosities Negligible maintenance High pressure capability High pressure capability High efficiency Axial flow - no churning, chewing or shearing Axial flow - no churning, chewing or shearing Self priming Excellent suction capability Excellent suction capability Smooth pulsation free flow Hydraulic balancing of forces eliminates need for any bearings Hydraulic balancing of forces eliminates need for any bearings Low noise and vibrations Typical Applications Fuel Oil Service:Fuel oil burner service for Thermal Power Plant/ Industrial Package, Boilers, Furnaces, Kilns and Combustion systems. Fuel transfer and booster service for Captive Diesel/ Gas Turbine Plants and Industrial Combustion Systems, Fuel Oil Circulations and Centrifuge Feeding. Tank farm tank to tank transfers. Hydraulic Duties :Hydraulic governing service for Water Turbines, Inlet Penstock Valves. Low and medium pressure hydraulic applications, high pressure jacking oil service for rotor lifting for Turbines/ Compressors/ Alternators. Lubricating Duty :Pressure lubrication and cooling of bearings for Turbo Machinery, Gear Boxes, Bearing Lubrication of Coal Mills, ID/FD Fans, Diesel Engines, Steel Rolling Mills, Air pre-heater guide bearings, Compressors. Seal Oil Service :Hydrogen cooled Generators, Gas and Refrigeration Compressors.

triple screw pumps

100,000 Per unit

Triple Screw Pump

Get Price Quote

Single, double and triple screw pumps for various kind of liquid application in various industries and spares for these pumps.

Triple Screw Pump

Get Price Quote

Triple Screw Pump

Get Price Quote

1 Piece (MOQ)

Three Spindle Screw Pump

Get Price Quote

Three Screw Pumps" already in 1970's. Foreseeing the growing demand for totally reliable fuel and lube oil pumps for Thermal and Hydel Power Plants, Fertilizer, Chemical and Steel Projects a beginning was made by importing critical components and building pumps locally. Over decades, thousands Three Screw pumps have been manufactured and delivered. Three Screw pump technology but equally in the other types - namely Twin Screw, Single Screw Progressing Cavity - as well as the conventional types like Shuttle Block, Internal Gear, External Gear, Trochoidal and Vane types.