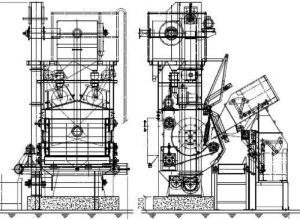

Industrial Tumblast Shot Blasting Machine

1,500,000 - 2,500,000 Per Piece

1 Piece (MOQ)

tumblast shot blasting machine

Get Price Quote

Airless Shot Blasting Machine Tumblast TypeThese machines are sturdy, rugged and proven across a wide variety of working conditions. They have been designed to carry out the multifarious jobs of cleaning and peening in faster time and of abetter quality than all other makes of the machine. The latest design of blast wheel is incorporasted, in order, also to keep the maintenance costs singificantly low. The ruber conveyor belt is rugged an given long life. Hence the machine is most economical in operation.Dust collector options are avaible i.e. Fabric. Cartridge type, as per your choice, The machine is avaible with vaious additional opional features like auto-mechnaical loader, program-logic Control system Time Contro, Electroni Brake system for blast wheel sound reducer etc, Please select the optional features as per your choice. Tumblast Shot Blasting Machine Ab-atb-20” X 27” Ex-works Price 4.0 To 5.0 Lac Processing Time – 4 Week Minimum Order Qty – 1 Supply Ability Per Month – 5 Nos Tumblast Shot Blasting Machine Ab-atb-27” X 36” Ex-works Price – 6.5 To 8.0 Lac Processing Time – 4 Week Minimum Order Qty – 1 Supply Ability Per Month – 5 Nos Tumblast Shot Blasting Machine Ab-atb- 36” X 42” Ex-works Price – 11.0 To 12.0 Lac Processing Time – 6 Week Minimum Order Qty – 1 Supply Ability Per Month – 2 Nos Rotary Barel Shot Blasting Machine Ab-atb- Rbf-1 Ex-works Price – 3.0 Lac To 3.5 Processing Time – 4 Week Minimum Order Qty – 1 Supply Ability Per Month – 5 Nos Rotary Barel Shot Blasting Machine Ab-atb-rbf-2 Ex-works Price – 4.0 Lac To 5.0 Lac Processing Time – 4 Week Minimum Order Qty – 1 Supply Ability Per Month – 5 Nos

Best Deals from Tumblast Shot Blasting Machines

Tumblast Type Shot Blasting Machine

Get Price Quote

tumblast shot blasting machine

350,000 Per piece

1 piece (MOQ)

tumblast shot blasting machine

Get Price Quote

Tumble Blasters process multiple parts, ranging in size from small to medium, with a level of speed and efficiency unmatched by other types of equipment in a comparable price range. Plus they are simple to operate. The operator loads parts onto a rugged perforated belt, closes the loading door, sets the timer and pushes the start button. By tumbling parts within the blast envelope, these machines deliver consistent results automatically whether working intermittently or non-stop in a multi-shift production facility.

tumblast shot blasting machine

Get Price Quote

Tumblast shot blasting machine is available in three sizes. Recommended for blast cleaning shot peening of small to medium size components in batched quantity.

Tumblast 36"x42" Shot Blasting Machine

Get Price Quote

tumblast shot blasting machines

900,000 Per Piece(s)

1 Piece(s) (MOQ)

The above machine is used for cleaning of castings and forgings, removal of heat scales, increasing pressure withstanding capacity of die castings, shot blasting of springs / gears etc. to increase their fatigue life, replace acid pickling and many other special applications for relatively small components. The efficiency and rugged design of this machine increases production, improves quality and reduces cost at the same time. Faster and better cleaning, leads to faster machining and grinding, saves labor, space, equipments, saves power, cut tooling cost, reduces rejection by easier inspection at the early stages, provide excellent bonding surface and gives uniform shot blasting for increase life. We strongly recommend our airless centrifugal shot peen machines with dust collection chambers. The components are continually tumbled during the abrasive blasting process and dust collection, filter bags are shaken after blasting operation by electrically operated mechanism.

Auto Door Tumblast Shot Blasting Machine

650,000 Per Piece

1 Piece (MOQ)

tumblast machine

Get Price Quote

Standard Tumblast machines are the flexible, low-cost solution to batch clean tumble-proof components in the most efficient and economical way. This machine has multiple applications such as : It is used for the descaling of heat treated and forged parts. It can be used for the desanding of components which are either ferrous or non ferrous. It can be also used on metallic and non-metallic parts for deburring. Die cast parts can be deflashed with it. It can also be used for the removal of contamination. Features Compact design, simple operating principle Forced but gentle turning and tumbling of the parts for all-round shot impingement Targeted high performance shot blasting for specific applications Continuous and thorough shot removal The tumbling action of the belt conveyor ensures that components are continually exposed to the blast stream and completely cleaned. For easy unloading, the belt conveyor is reversed, delivering the components into the loading skip or stillage. Optimized shot blast effect During shot blasting, the work pieces, regardless of size and shape, are evenly and continuously tumbled. This is necessary for the effective and uniform treatment of all surfaces. During tumbling, the work pieces continually undergo shot removal, enabling work piece interiors and cavities to be perfectly cleaned For the complete removal of all shot, the final tumbling time that follows the shot blast sequence can be regulated to suit the type of work pieces being blast cleaned The tightly sealed, leak-proof blast chamber minimizes shot consumption Steel/Metallic conveyor or rubber belt conveyor (depending on machine size and application) Space-saving, ergonomic design Distortion-resistant rigid housing Process-appropriate blast chamber shielded with large, smooth, and highly wear resistant liners especially designed to withstand abrasion by shot impact Gravity /Rotary/ magnetic separation systems Special design for use of aluminum abrasive Removal of shot, sand, or scale via screw conveyor Magna valves (optional) Ergonomic maintenance platform Adequate loading / unloading systems Dust removal system

tumblast shot blasting machine

Get Price Quote

1 Piece (MOQ)

Tumblast Type Shot Blasting Machine 300 Kgs Capacity

385,000 - 535,000 Per Unit

1 Set(s) (MOQ)

tumblast shot blasting machine

1,800,000 Per Set

1 Set (MOQ)

tumblast shot blasting machine

650,000 - 1,200,000 Per piece

Centrifugal AutobTumblast Shot Blasting Machine suitable for Batch capacity of 200- 500;kgs

tumblast type shot blast machine

520,000 - 4,000,000 Per No

1 Set (MOQ)

Tumblast Type Shot Blasting Machine

Get Price Quote

1 Piece (MOQ)

Tumblast Type Shot Blasting Machine Manufacturer Features : Compact design, simple operating principle Forced but gentle turning and tumbling of the parts for all-round shot impingement Targeted high performance shot blasting for specific applications Continuous and thorough shot removal The tumbling action of the belt conveyor ensures that components are continually exposed to the blast stream and completely cleaned. For easy unloading, the belt conveyor is reversed, delivering the components into the loading skip or stillage. Applications: It is used for the descaling of heat treated and forged parts. It can be used for the desanding of components which are either ferrous or non ferrous. It can be also used on metallic and non-metallic parts for deburring. Die cast parts can be flashed with it. It can also be used for the removal of contamination. During shot blasting, the work pieces, regardless of size and shape, are evenly and continuously tumbled. This is necessary for the effective and uniform treatment of all surfaces. During tumbling, the work pieces continually undergo shot removal, enabling work piece interiors and cavities to be perfectly cleaned For the complete removal of all shot, the final tumbling time that follows the shot blast sequence can be regulated to suit the type of work pieces being blast cleaned The tightly sealed, leak-proof blast chamber minimizes shot consumption Steel/Metallic conveyor or rubber belt conveyor (depending on machine size and application) Space-saving, ergonomic design Distortion-resistant rigid housing Process-appropriate blast chamber shielded with large, smooth, and highly wear resistant liners especially designed to withstand abrasion by shot impact Gravity /Rotary/ magnetic separation systems Special design for use of aluminum abrasive Removal of shot, sand, or scale via screw conveyor Magna valves (optional) Ergonomic maintenance platform Adequate loading / unloading systems Dust removal system The tumblast shot blast machines are an excellent method to clean and finish quantities of components such as castings and little fabrications. The conveyor belt gives the tumbling action to detect all areas of the components to the blast stream, to assure complete cleaning in one cycle. After the blast cycle, the automatic reversal of the conveyor removes the components ready for further processing. Tumble Belt shot blasting machine Suitable For Shot Blast cleaning of small forging, casting or heat-treated parts Shot Blast cleaning of bulk manufactured parts like nut, bolt, washer, automobile components etc. Shot Blast cleaning of big parts suitable for tumbling Deburring Deflashing Degreasing Scale removal Rust Removal Shot peening.

tumblast shot blasting machines

350,000 - 950,000 Per piece

Tumblast Type Shot Blasting Machine

800,000 - 2,000,000 Per INR

Tumblast Type Shot Blasting Machine is designed to carry out the different jobs of cleaning and peening. We are a prominent Tumblast Type Shot Blasting Machine Manufacturer, Exporter and Supplier in Rajasthan (India). Our Tumblast Type Shot Blasting Machine is easy to operate and has long functional life. We can customize our Tumblast Type Shot Blasting Machine as per the customer’s provision. Process : The door of the machine is opened and components are loaded on to the endless rubber conveyor belt of the machine manually with loader arrangement Then the door is being closed and blasting operation takes place The abrasive at high velocity falls upon the tumbling components and clean them The rubber conveyor belt tumbles the components gently and ensures adequate exposure of the components After blast cleaning cycle is over, the blast wheel is shut off and door is opened The components are unloaded on the trolley by moving the conveyor belt in reverse direction

tumblast shot blasting machine

Get Price Quote

1 Piece (MOQ)

Brake Shoe Tumblast Shot Blasting Machine

150,000 Per Piece

1 Piece (MOQ)