Tumbling Machine

Get Price Quote

2 Piece (MOQ)

A tumbling machine is a durable deburring and metal-polishing machine designed for finishing large parts or batches of smaller parts. A tumbling machine is also known as a barreling machine or a mass-finishing machine.

Stone Tumbling Finishing Machine

Get Price Quote

1 Piece (MOQ)

We take pride ourselves in offering a superior range of Vibratory Trough, which is fabricated using best grade raw materials that are sourced from reliable vendors in the market. This equipment is offered in, both, batch and continuous operations. Dryer Vibratory Machine is strongly built with extra Gussets on bowl, higher hp motor & heavy duty spring to withstand. These tested on various parameters

Best Deals from Tumbling Machine

Automatic Tumbling Belt Deflashing Machine

Get Price Quote

Tumbling Barrel Test Machine

Get Price Quote

Tumbling Barrel Test Machine is used for testing mechanical strength of electrical switches of 6A/16A/32A. Control panel made up of MS powder coated finish with wooden tumbling barrel as per IS specification with sliding acrylic door. The wooden tumbling is freely rotated at a constant speed of 5rpm by the constant speed gear motor. Digital rotation counter cum indicator controls the number of rotation of the wooden tumbling barrel. The number of rotation is fully programmable and settable with the help of membrane keys of digital rotation counter.

FINEX TUMBLING MACHINE

Get Price Quote

Tumbling Machine catalogue:It is a unique simulation of hand screening by the eye. The mechanical simulation is achieved by the Tumbler screening machine which works on the principle of gyratory motion which enhances the horizontal motion of the plain sifter. The eccentricity speed can be varied to vary the residence time of the powder to be screened.The three dimensional tumbling motion distributes the screening material over the entire surface of the screen. Gentle low frequency and high amplitude movement increases the screening efficiency without screen blinding. Ordinary motors are being used with pulleys to generate tumbling motion. Accessories such as top and bottom rotating brushes are offered to prevent screen blinding to take place.Sizes offered are from 24 inch to 72 inch Diameter.From Single deck to multiple decks of 5 screens,6 separation are available.It can handle in feed of material from 100 kgs to 10,000 kgs per hour.It is used for screening and grading of powders from 10 mesh to 400 mesh.It can be fabricated in Carbon steel and Stainless Steel.

Tumbling Machine

130,000 Per Piece

Tumbling Machine

Get Price Quote

Agm battery separator our rich industry experience in this field enabled us to provide highly qualitative agm separator to our reputed clients. Approx price: rs 290 kilogram features: long lasting fine finish easy to use accurate in size high strength

Tumbling Machine

Get Price Quote

Vibro Finishing Machine Vijimech Vibro finishing machine is a bowl type centrifugal finishing machine. The machine bowl is loaded with suitable ceramic plastic or steel media and the components be processed. The mutual rubbing action takes place inside the chamber due to the gyratory vibrations, Compared to other simpler processes this method completes the deburring process faster.

Tumbling Barrel Machine

180,000 Per Units

Tumbling Machine

Get Price Quote

Tumbling Machine, Cultivator, agricultural consultant

Tumbling Machine

432,000 Per Unit

Stone Tumbling Machine

70,000 Per Units

Granite Tumbling Machine

700,000 Per Piece

1 Piece(s) (MOQ)

Tumbling Machine

Get Price Quote

Evaporation of moisture from all types of Linen, Garments and Textile Made up Articles after they come from Washer Extractor or Hydro Extractor,Stainless Steel Cylinder. Microprocessor Control. Reversible.15, 30, 60, 120 and 200 kg Capacity.

Tumbling Machine

295,000 Per Piece

1 Piece (MOQ)

Manual Tumbling Machine

Get Price Quote

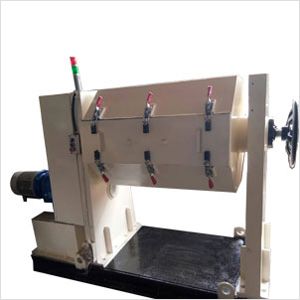

Drum Tumbling Machine

Get Price Quote

Drum Tumbling Machine Quantity At One Time Is 50-60 Pieces Per Slot (25 To 35 Mm Thick) And More Then 300 Cobal Or Bricks Are Also Tumble With It At A Same Time. Size of Stone Can Be Tumbled Are Up To (90 X 90) MM. 100% Maintenance Free. No Consumables Are Used. (Water & 10hp Three Phase Electricity Connection)

Tumbling Machine

65,000 Per Unit

1 Unit (MOQ)

Rumbling Machine

Get Price Quote

This machine is used for Lubricating of Slugs with zinc sterate powder prior extrusion process. The machine is very compact in design; the drive is done through motor by a reduction gear box. The machine design in Hexagonal Drum shape.

Stone Tumbling Machine

Get Price Quote