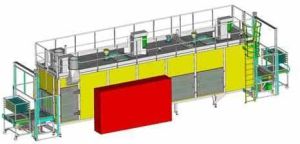

tunnel type oven

1,500,000 - 15,000,000 Per Piece

We manufacture sophisticated range of Tunnel Type Oven. Tunnel Type oven is preferred by various industries where production volume is fairly large and continuous. Our Tunnel Ovens are categorized by incomparable suppleness and can be used for all types of products. Features Best performance Low maintenance Durable Low fuel consumption Long lasting Safe operation Applications Mainly used for baking

Tunnel Oven

Get Price Quote

1 Piece (MOQ)

Our company’s name figures in the list of top Manufacturers and Suppliers of high-grade Tunnel Oven. The Tunnel Oven that we offer are precisely engineered using premium raw material in our state-of-the-art manufacturing unit. Used for baking biscuits, cakes and other similar kinds of food, we them available in different specifications as per the requirements of customers. Our strong distribution network facilitates timely of our products across the country. For discounted prices, contact us. Baking Scop : Bread Cake, Mooncake, Biscuit, Toast, Baguette and other kings of similar food. Product Categories : According To customers requirements, we can offer electrical type, LPG type. natural gas type and the length and width can also be customized.

Best Deals from Tunnel Oven

Suncross Tunnel Oven

4,000,000 Per Piece

1 Piece (MOQ)

CUSTOM DESIGNED TUNNEL OVENS

Get Price Quote

SAKAV has designed and manufactured tunnel ovens for all types of processing. These ovens have been designed for use with a wide range of existing conveyor systems. Since 1985 we have been providing electric gas and steam heated units with operating temperatures from 650C to 6500C. Tunnel ovens are designed to include support points for your conveyor system. Adjustable silhouette dampers are provided on the oven end openings to minimize heat loss. Each Oven is designed for the specific application and can include multiple heat zones and a cooling zone. Units can be provided in sections for easy installation and mating with existing conveyor system. Our experienced engineers will work closely with you to develop a tunnel oven to readily accept your conveyor system. Every unit is completely assembled and tested prior to shipment STANDARD FEATURES Aluminized or stainless steel interior depending on maximum temperature rating. 16 gauge aluminized steel exterior with enamel finish Welded structural steel, channel base provides a rigid assembly easily moved at any time. Heavy duty, all welded, structural steel slide bed is supported by cross angles welded to vertical structural members to transfer load to base Side hinged doors provided along oven length for access to work space and heat chamber. Adjustable dampers at each end of heat zone can be positioned near load to minimize heat loss from end of oven. Adjustable patented opposed louvers on full coverage supply and return ductwork. Duct work removable for cleaning Control Panel Brushed stainless steel control panel face 1 year limited warranty. TUNNEL OVEN LENGTH Tunnel oven width is selected to accommodate the parts and conveyor system. The speed of the conveyor system and the dwell time determine tunnel oven length. Heat zone length is the product of the conveyor speed and dwell time. To estimate the length of tunnel over required, insert your process information in the relationship below. To heat zone length calculated, approximately one foot must be added for insulation and silhouette dampers at each end of the oven. Equipment width will be approximately 2' wider than tunnel work space width to accommodate insulation, ductwork and control enclosure. To receive a detailed quotation for your application complete the "Request for Quotation Data Sheet" found on the reverse side of our catalog index. (Conveyor speed of ___ feet per hour) x (Dwell time of __ hour) = (Heat zone length of______ feet) STANDARD EQUIPMENT All Models - 230 volts, 3-phase, 50Hz - Other electrical characteristics available Vertical downward air flow between full coverage ductwork above and below conveyor belt. Other air flow patterns available. Trilite Green enamel painted aluminized steel exterior. Electric Models Each features completely wired, side access control panel enclosing terminals for incoming power, temperature controllers, push buttons and pilot lights. Motor starter and heating element contactors electrically interlocked to shut off heaters if power to blower is interrupted and to permit operation of blower without heat for cooling. Incoloy sheathed tubular heating elements. Gas Models - 1,000 BTU natural gas at 6" water column pressure; - Other gas characteristics available Control panel as on electric models. Automatic preignition purge period and push button electric ignition contributes to ease of operation. Modulating gas burner is protected with electronic flame safety relay.

Tunnel Ovens PCB IR

650,000 Per Piece

1 Piece(s) (MOQ)

tunnel ovens

Get Price Quote

Tunnel Oven

Get Price Quote

With our brilliant logistics network, we can furnish urgent and massive requirements of the buyers with ease. As we have marked a distinct name in the market, we are recognized as the trusted organization for supplying quality Tunnel Oven.

Tunnel Oven

Get Price Quote

Our company stocks the product in mass. Thus, we can cater to bulk/retail requirements with easy and ensure fast delivery of product. Designed and developed using the premium raw material and modern work methods; we guarantee high quality standards and longevity of our products. Also, we make sure that the raw material is sourced from the trusted places.

Tunnel Oven

Get Price Quote

One of the most renowned Manufacturers, Exporters and Suppliers of Tunnel Oven; we offer the most reliable and certified Ovens. We have rich industry experience that we have used to bring forth the quality assured and tested Tunnel Oven for different types of processing; manufactured under the watchful supervision of experts. We offer Tunnel Oven that is stringently controlled by a PLC thus includes complete temperature recording facilities. The Tunnel Oven has conveyors that are designed to run continuously with pneumatic vertical doors at the feed and discharge ends of the conveyors.

tunnel ovens

Get Price Quote

These ovens have been designed for use with a wide range of existing conveyor systems. We provide electric gas and steam heated units with operating temperatures from 650C to 6500C. Tunnel ovens are designed to include support points for your conveyor system. Adjustable silhouette dampers are provided on the oven end openings to minimize heat loss. Each Oven is designed for the specific application and can include multiple heat zones and a cooling zone. Units can be provided in sections for easy installation and mating with existing conveyor system.

Electrically heated Tunnel oven

Get Price Quote

Electrically heated Tunnel oven for curing depressed center wheels

Tunnel Oven

Get Price Quote

Critical conponents such as chain is made in Japan,PLC control is made by Siemens.Each tunnel oven is tailor-made according to customers'product and capacity requirement. Available xith gas burner or electric heating clement.For gas tunnel oven,each burner can be switched on or off while other burner are working.For electric heating tunnel oven,the power of each electric heating element can be adjusted to meet product requirement.

Gas Tunnel Oven

Get Price Quote

Industrial Polymerization Tunnel Ovens

Get Price Quote

We are leading manufacturer and supplier of Polymerization Tunnels. Our product range comprises of various types of polymerization tunnels. Specifications: Hot-water heated batch oven 2 heating zones & one cooling zone. Parts on carts

Tunnel Oven

Get Price Quote

Tunnel Oven

Get Price Quote

Tunnel Oven

Get Price Quote

Tunnel ovens are designed to include support points for your conveyor system. Adjustable silhouette dampers are provided on the oven end openings to minimize heat loss. Each Oven is designed for the specific application and can include multiple heat zones and a cooling zone. Units can be provided in sections for easy installation and mating with existing conveyor system. FEATURES: 1 Aluminized or stainless steel interior depending on maximum temperature rating. 2 Welded structural steel, channel base provides a rigid assembly easily moved at any time. 3 Side hinged doors provided along oven length for access to work space and heat chamber.

Bread / Bun Baking Tunnel Travelling Oven

Get Price Quote

We are offering Bread / Bun Baking Tunnel Travelling Oven.

Tunnel Oven

Get Price Quote

This style of oven is similar to web dryers in that the product is normally spool to spool or continuously run unsupported through the oven. Some applications include heat shrinking, curing and drying for inks and coatings on wire, cable, and tubing; preheating composite lumber prior to embossing; post heat extrusionspultrusions, and curing paint on sheet metal coils. Tunnel and clam shell ovens are custom built with removable side panels or hinged housings for easy product threading and maintenance. ovens are designed to be installed quickly, with a minimum of field wiring or preparation required. They are completely factory assembled, set up and tested prior to shipment to assure a simple trouble free start up.

Tunnel Microwave Ovens

Get Price Quote

Microwave Tunnel for the production of ingots of gold and silver A tunnel oven for the continuous production of gold bullion and silver in a controlled atmosphere. The melting of metals takes place in ingot molds of isostatic graphite by electromagnetic induction. This unit includes the following parts:1. Loading Zone2. Melting Zone3. Zone solidification4. Cooling Zone5. Unloading zone6. Power ConverterLoading Zonescroll -Piano in tapes for the automatic loading of the ingot in the pushing ramp.Motorized -Spintore for precise positioning of the bracketsMelting Zone-room fusion with adjustment of the operating temperature: ~ 1200 ° C.-System induction heating.-Area melting enclosed by panels of insulating materials with an inert gas inlet at the entrance of the brackets.-Avanzamento of the brackets on tubular guides cooled steel AISI310-Monitoring and temperature adjustment by means of pyrometers (working range 600-1800 ° C) with on the operator panel display.Solidification ZoneArea which allows the withdrawal of the cast ingot management; self-regulating system in relation to the following parameters:• ambient temperature• cooling water flow• cooling water temperatureThe system allows to ensure the highest quality of the surfaces of the finished ingot.Cooling Zonecooling -Double protected and closed.Room -Length studied to better control the cooling curve (the brackets with the ingots must exit at a temperature of ~ 30-40 ° C)Unloading zone-tape of ejection of the ingot from the cooling chamber-Piano scroll for the storage of melted ingots.Dimensions of Ingots:▪ Lingotto 100 oz Ag▪ Lingotto from 1000 g Au, Ag▪ Lingotto 500 g Au, Ag▪ Lingotto 250 g Au, Ag▪ Lingotto 100 g Au, Ag▪ Lingotto 50 g Au, Ag▪ Lingotto 1 Oz Ag▪ Lingotto 10 tolas Au