Twin Screw Pump

Get Price Quote

1 Piece (MOQ)

It is capable of handling both product transfer and Cleaning-in-Place (CIP). Its low pulsation characteristics and excellent solids handling capability reduce the risk of product damage.

Twin Screw Pump

Get Price Quote

Features : Positive clearance between rotors ensures no metal to metal contact. This unique feature enables to run the pump even dry for some time without any damage & wear and tear is reduced to the minimum ensuring extremely long service life. Can handle fluids that do not have enough lubricating value and also very low or high viscous products. Lowest NPSHR, Axial smooth steady flow & Pulsation free output. Partial heating / complete heating / cooling arrangements are also offered. Available with Inbuilt Relief Valve.Applications : Loading and Unloading of Fuel Oil and other products from Railway Wagon Rakes, Truck Tankers, Barges, Ships and Tankers. Bulk Cargo Handling. Lubrication, Circulation and Cooling. Long Distance Pipeline Pumping of Viscous Products. Process Pumping of Products like Bitumen, Molasses, Additives, Paraffin, Polyester, Lyes, Residues, Etc.

Best Deals from Twin Screw Pump

Twin Screw Pumps

Get Price Quote

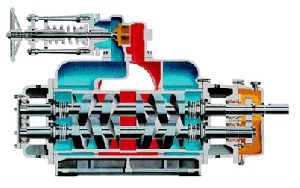

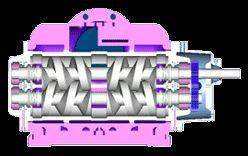

The working principle of Hydro Prokav dual flow Twin Screw Pumps is dependent on the rotation of the two screw spindles in the closed compartment. There is always a predefined fine clearance exists between the outside diameters of the screw spindles and the casing bore/ liner in which the screw spindles are located. Each half of the screw spindles is left handed and right handed thus when the spindles rotates, driven by the timing helical gears located at the end of the screw. The liquid is drawn towards the end of the screw and entrapped between the bore of the pumping compartment as well as the flanks of the screws and is then propelled axially from both the ends towards the centre. Such a dual flow nullifies the axial thrust completely, thereby enabling the screws to remain in a state of hydraulic balance resulting in high volumetric efficiency and overall efficiency. Salient Features High volumetric efficiency High suction lifts without cavitation Self priming and ability to handle air vapour and gas in fluids No axial thrust Long and trouble free service life with safety in operation and user friendly design Uniform metered flow Ability to handle different types of liquids and fluids Conforms and adheres to API 676, 2nd edition Dry running capability Negligible wear over years Axial smooth steady flow High speed running Pulsation free output Negligible vibrations Intensive to varying viscosities Long maintenance free service Lowest NPSHR Interchangeable liner Adaptability of various MOC Shaft sealing at suction pressures Axial thrusts completely eliminated No metal to metal contact between rotors Positive clearance between rotors Confirming to API 676 Standards Mounting: Horizontal Internal Bearing pumps Horizontal External Bearing pumps Jacked Pumps Vertical Pumps Fluids Handled (applications) Fuel Oil LSHS HPS RFO Crude Oil Vacuum Residue Wax Bitumen Mineral Oil Turbine Oil Hydraulic Oil LDO Kerosene Oil Naphtha Lubricating Oil Molasses Black Liquor Polymeric Resins Lacquers Cosmetic Creams Detergents Soaps Glucose Jelly Fats User industries Petro Chem icals Refineries Oil Storage Depots Bunkering Stations Power plants Marine Shipping Sugar Industries Steel Industries Paper Industries Textile Industries On shore and off shore Exploration

Twin Screw Pumps

5,000 - 600,000 Per 1

A pair of specially profiled screw, machined integral from solid stock and well supported on antifriction bearings run in precision bored interchangeable casing liners.

Twin Screw Pump

Get Price Quote

Twin Screw Pumps are designed for pumping contaminated or slightly abrasive liquid, lubricating and non lubricating media of low or high viscosity which do not chemically attack the pump materials. These are double entry pumps and the shaft spindle is axially held in position by ball bearings. Single unbalanced mechanical seal is used keeping the liquid pumped isolated from the bearings and gearbox. A spring loaded built in relief valve is used to protect the pump from overloading.

Twin Screw Pump

Get Price Quote

Twin Screw Pumps

Get Price Quote

We are counted among the reliable Manufacturers and Suppliers of Twin Screw Pumps. Our Twin Screw Pumps are made using the finest grade components that enhance the performance and durability. The Twin Screw Pumps, provided by us, are widely installed in industrial sectors for performing different tasks such as Water based paints, bulk transfer of fluids etc. Besides, we provide these Twin Screw Pumps at the most reasonable prices to valuable clients. Details Discharge : Up to 8000 lpmDifferential Pressure : Up to 16 barViscosity : 1 to 50,000 cSt Typical Applications LoadingUnloadingBulk transfer of different fluids ranging from fuel oil to Bitumen SplApplication Water based paints

W-UTPSPL Rotary Twin Screw Pumps

Get Price Quote

The W-UTPSPL Rotary Twin Screw pumps have external bearings and can handle all types of viscous media. These self priming W-UTPSPL Rotary Twin Screw Pumps can even handle homogenous fluids. About W-UTPSPL Rotary Twin Screw Pumps Has a maximum power of 40 Bars.Maximum temperature of 300 degree C Required By Chemical industryPetrochemical industryMarine Shipbuilding industry

Twin Screw Pump

Get Price Quote

1 Piece (MOQ)

We are offering twin screw pump. • absolutely no metal-to-metal contact between the moving screws as a small positive clearance is maintained between them. This ensures the pump very long operational service, resulting in no wear and tear of pump parts. • pump capable of running dry • screws are mounted on the timing gears and the speed of both the screws are therefore synchronized resulting in pulsation free, turbulent free flow • flow of the liquid is always in the straight path • sealing is situated at the suction pressure • pump requires very low npsh (net positive suction head) • the rotation of screws is perfectly balanced resulting in no vibration and negligible noise.

Twin Screw Pump

Get Price Quote

Twin screw pump, Twin screw pumps with separate timing gears are applied for pumping non-lubricant fluid. Twin screw pump without timing gears are designed for transferring fluid with little lubricant. Three screw pumps with meshing cycloid are used for delivery of lubricating fluid. The unique twin screw Granulators are specially designed for Polyacrylamide granulating.

Twin Screw Pumps

Get Price Quote

Horizontal Twin Screw Pump

150,000 Per Piece

1 Piece(s) (MOQ)

Roto’s horizontal external bearing Twin Screw Pumps find its suitability for handling fluid that shows different characteristics at different temperatures. These pumps are available in standard foot mounted & center-lined mounted configuration with or without steam jacketing arrangement. Guarantees reliable running and long life for all liquids whether it is neutral or aggressive. Mechanical seals are standard. Option for gland packing is also available. Pumps are fitted with relief valves suitable for 100% bypass. The suction and discharge ports are in-line. Brand Name - Roto Pumps Ltd. Web Link - https://www.rotopumps.com/pd-pumps/twin-screw-pumps/horizontal-external-bearing/External Bearing RE Pump Due to its external bearing mounted design, the product does not come in contact with the bearings and ensures long service life even with the corrosive or abrasive nature fluids. These 0 pumps can handle fluids with high temperatures up to 3500C / 0 6600F. API 682 type seals can be mounted. Built-in safety relief valve designed for 100% bypass. Material Options:Casing:• Cast Iron, • Cast Steel, • Fabricated Steel • Fabricated Stainless SteelLiner:• Case Steel • Stainless SteelScrews:• Alloy Steel • Stainless Steel, • Hardened SteelTiming Gears:• Hardened SteelOther Exotic Materials:• Duplex • Super DuplexScrew Surface Coating:• Hard Chrome PlatingPrice Range: Rs. 1.5 Lac-Rs. 50 Lacs* * Minimum prices are mentioned for smallest model Bare Shaft Pump. Prices may vary for complete Pump set with motor & accessories and for exotic material options or customized pumps.

Twin Screw Pump

12,000 Per Piece

Twin Screw Pump

Get Price Quote

Progressive Cavity Pumps which are also commonly known as Eccentric Screw Pumps or Helical Rotor Pumps operate employing a unique pumping principle. A high precision metallic single helical rotor rotates inside a double helical resilient stator forming a uniform seal line & cavity which is maintained at stand still or during rotation. To cater to the various types of Industries, Visflow Pumps offer the full range of products which are catagorised as under:

Twin Screw Pumps

Get Price Quote

Features Capable of Higher capacity / Bulk Liquid Handling No metal to metal contact between rotors Long life in service Dry running capability Lowest NPSHR Low Noise & Vibration Mounting type- Horizontal Foot, Horizontal Flanges, Vertical pedestal MOC-Cast Iron, Cast Steel, Fabricated Carbon Steel, Stainless Steel & etc., Sealing – Gland Packing, Grafoil Packing , Mechanical seal Description Application:- Loading / unloading of Lube Oil , Fuel oil and any industrial liquids Railway wagon , Truck tankers, Ships and Tankers-Bulk cargo handling. Lubrication, circulation and cooling. Process pumping of high viscous products, bitumen, molasses, soap and similar products. Long distance pipeline pumping of viscous products

Twin Screw Pumps

Get Price Quote

TWIN SCREW PUMPS –TD OPERATING RANGE: Typical Applications Loading & unloading of fuel oil and other products from: Railway wagon rakes, Truck tankers, Barges, Ships and Tankers, Bulk cargo handling Process pumping of high viscous products such as bitumen, molasses, soap and similar products Long distance pipeline pumping of viscous products. MOC • Cast iron / SS 316.

Jung Process Systems pumps

Get Price Quote

Jung Process Systems is a German manufacturer of the HYGHSPIN series - twin screw pumps known for their hygienic, high performance and gentle treatment of aqueous or viscous media. These pumps are specially designed for the food & beverage, dairy, confectionary, cosmetics, and pharmaceutical industries. We have taken up sole distributorship in India in 2015 General Features Pumps aqueous or highly viscous media. High suction performance. Product and CIP can be handled with only one pump. Pumping of fibrous media and products containing pieces. Abrasion-free gentle treatment: no contact between feeding elements. Supply rates up to 200 m3/hr. EHEDG and GOST-R certified. Simple assembly and disassembly.

Twin Screw Pump

Get Price Quote

Discharge : Upto 8000 lpm Differential Pressure : upto 16 bar Viscosity :1 to 50,000 cSt Typical Applications Loading, Unloading, Bulk transfer of different fluids ranging from fuel oil to Bitumen Spl. Application Water based paints.

Twin Screw Pump

4,000 - 20,000 Per Piece

Twin Screw Pumps

Get Price Quote

The working principle of Hydro Prokav dual flow Twin Screw Pumps is dependent on the rotation of the two screw spindles in the closed compartment. There is always a predefined fine clearance exists between the outside diameters of the screw spindles and the casing bore liner in which the screw spindles are located.