waste tyre recycle plant

Get Price Quote

We are manufacturer & exporter of waste tyre pyrolysis plants with 5 - 10TPD processing capacity. Pyrolysis plant is an industry that converts scrap tyres into Pyrolysis Oil, Carbon Black, Scrap Steel and Hydrocarbon Gas. The plant is manufactured using high quality material, is highly durable and has high performance level. To manufacture these plants, we make use of quality-approved components that are source from certified vendors. Features : 100% of waste tyre recycling is achieved ( no waste left after the process ) No chemical ingredients are used in process ( environment friendly ) During and after the process, No soil, water or air pollution is observed Creates economically valuable products out of waste ( all of the products are industrial raw materials that have a market value ) The most cost - effective waste tire recycling technology in the world Raw material ( waste tyre ) is cheap and easy to provide. These are the by-products of tire production Each recycled ton of tyre preserves 10 tons of Co2 that is a major green house gas The process can be applied to all rubber based materials The system creates an alternative source of energy to replace petroleum products and natural gas System gives the opportunity to governments and local administrations to deal with the waste tire problem to a great extent System prevents the spread of diseases caused by the waste tires We deliver plants with capacities of 10 ton per day and its multiples The process of pyrolysis has duration of 4 to 12 hours, depending on the amounts and the type of tire ( car tires, truck tires etc) During the process different vacuum values are applied in pre determined temperatures and in different phases, different gases are obtained and the condensed gas is stored as fuel - oil in tanks.

10 Ton Waste Tyre Recycling Pyrolysis Plant

4,500,000 Per Set

1 Set(s) (MOQ)

Best Deals from Tyre Recycling Plant

Semi-Automatic Waste Tyre Recycling Plant

Get Price Quote

Waste Tyre Recycling Plant

Get Price Quote

To cater to the variegated demands of the customers in various industries, we are offering the qualitative range of Waste Tyre Recycling Plant at modest rates. Our Recycling Plant is noted for its features like efficient operation, smooth finish and long functional life. We are an illustrious Manufacturer, Exporter and Supplier from Gujarat, India and are offering Waste Tyre Recycling Plant to our prestigious buyers across the world.

Tyre Recycling Plant

Get Price Quote

tyre recycling plant.

waste tyre recycle plant

Get Price Quote

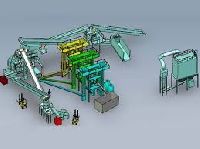

waste tyre pyrolysis full plant

Waste Tyre Recycling Plant

Get Price Quote

We are offering waste tyre recycling plant. We are from fab-india manufacturing of waste scrap tyre plastic recycling plants since last 5 years, fab-india already supplied 250+ plants in all over india & outside also like nairobi,nepal and more, with the waste tyre recycling plant you can produce pyrolysis oil , carbon black powder & steel scrap. Nad from selling above said products you can generate profit to respective market.

Tyre Recycling Plant

Get Price Quote

Waste tyre recycling pyrolysis plant of capacity 5 ton x 2 total 10 ton with all related machinery reactors, condensers, chimney, Systems Oil tanks, Storage tanks , Cooling tower, Electrical Panels & all necessary equipment's for run the both plants

Continuous Waste Tyre Recycle Plant

Get Price Quote

We are the main supplier of this product.

Waste Tyre Recycling Pyrolysis Plant.

Get Price Quote

We are manufacturer of the waste tyre recycling pyrolysis plant, we provide all kind of parts and sercive related to the machine and its equipments, which are of high grade quality raw materials. The plant that we manufacture are long lasting and of very good quality, at a very negotiable rate

Waste Tyre Recycling Plant

Get Price Quote

Waste tyre recycling pyrolysis plant of capacity 5 ton x 2 total 10 ton with all related machinery reactors, condensers, chimney, Systems Oil tanks, Storage tanks , Cooling tower, Electrical Panels & all necessary equipment's for run the both plants

Tyre Recycling Plant Manufacturer

Get Price Quote

1 Set(s) (MOQ)

We are offering Tyre Recycling Plant. Features of the plant: 100% recycling of tyre wastage is achieved (No churn left after the process) No chemical ingredients are used in process (environment friendly) During and after the process; no soil, water or air pollution is observed. Creates economically valuable products out of wastage tyres (These are an industrial product that have a good market value and demand) The most cost-effective wastage tyre recycling technology in the world. Raw material (wastage tyre) is cheap and easy to provide. These are the by-products of tyre production. Each recycled ton of tyres preserves 10 tons of CO2 that is a major green house gas. The process can be applied to all rubber based materials. The system creates an alternate source of energy to replace petroleum products and natural gas. System gives the opportunity to governments and local administrations to deal with the wastage tyre problem to a great extent. The process of Pyrolysis has duration of 4 to 12 hours, depending on the quantity and size of tyre (car tyre, truck tyre, etc.). During the process different vacuum values are applied in pre-determined temperatures and in different phases. Different gases are obtained and the condensed gas is stored as a fuel-oil in tanks.

Tyre Recycling Plant ( 05 Ton)

Get Price Quote

Waste Tyre Recycling Plant { 5 Ton } • 100% waste tyre recycling is achieved (no churn left after the process). • No chemical ingredients are used in process (environment friendly). • During and after the process; no soil, water or air pollution is observed. • Creates economically valuable products out of waste (all of the products are industrial raw materials that have a market value). • The most cost-effective waste tyre recycling technology in the world. • Raw material (waste tyre) is cheap and easy to provide. These are the by-products of tyre production. • Each recycled ton of tyre preserves 10 tons of CO2 that is a major greenhouse gas. • The process can be applied to all rubber based materials. • The system creates an alternative source of energy to replace petroleum products and natural gas. • System gives the opportunity to governments and local administrations to deal with the waste tyre problem to a great extent. • System prevents the spread of diseases caused by waste tyres. • We deliver plants with capacities of 5 ton day & 10 tonday and its multiples. • The process of Pyrolysis has duration of 4 to 12 hours, depending on the amount and type of tyre (car tyre, truck tyre, etc.). During the process different vacuum values are applied in pre-determined temperatures and in different phases different gases are obtained and the condensed gas is stored as fuel-oil in tanks.

Old Tyre Recycling Pyrolysis Plant

Get Price Quote

1 Set(s) (MOQ)

We are offering old tyre recycling pyrolysis plant. Old tyre recycling pyrolysis plant (6 months) eith good condition, 1 cooling tower, 1 carbon conveyer chain sell immediately .

Waste Tyre Recycling Plant

2,400,000 Per Piece

Waste Tyre Recycling Plant

Get Price Quote

1 Set(s) (MOQ)

We are offering waste tyre recycling plant. Product name list and other tyre pyrolysis machine main parts list: 1) main machine, the reactor with cover, and reactor base 2) oil separator 3) oil gas cooling system( pipe cooling system 10pipes(219mm*6m) and 5 condenser ) 4) heavy oil tank 5) light oil tank 6) waste gas recycling pipes, gas burners 7) water sealing tank (anti-fire system) 8) deducting system (process smoke, pollution-free) 9) draught fan 10) speed reducer 11) blowers 12) oil pump 13) water pump 14) control cabinet 15) waste wire pulling machine technical detail: ø this is a batch process system. ø the wastage tyres are fed into the reactor vessel and heated under controlled conditions of temperature and pressure. ø the process will bring about molecular restructuring of the rubber under the pyrolysis process as the result; furnace oil in gaseous form is produced along with other gases. ø these vaporized gases are passed through heat exchanges, where in the furnace oil is condensed into liquid form. ø during the process, carbon black and steel are also generated. ø the heat exchanger uses coolant water, as a condensing medium and this water is re-circulated through process. ø these systems can be operated 24/365. project planning & implementation (for the 10 ton/day capacity): construction shed approx. 4000 sq. Ft. water required. 100 liters per day power requirement 40 hp. manpower: worker 7 labours. technical 2 person manager 1 features of the plant ø 100% wastage tyre recycling is achieved (no churn left after the process) ø no chemical ingredients are used in process (environment friendly) ø during and after the process; no soil, water or air pollution is observed. ø creates economically valuable products out of wastage tyres (these are an industrial product that have a good market value and demand) ø the most cost-effective wastage tyre recycling technology in the world. ø raw material (wastage tyre) is cheap and easy to provide. These are the by-products of tyre production. special features: two catalyst room, in this way, can speed up the process of pyrolysis. two horizontal condenser, the cooling area of one horizontal condenser can be equaled with more than three vertical condensers. And also, the cooling way is longer than vertical condenser, in this way, the oil output will be guaranteed. equipment model jzm-02 material plastic rubber (tyres) life garbage structure horizontal tyre revolves capacity for one batch about 8-10 tons wastage tyres operating mode intermittent operation type of drive external annual gear drive output products: 1. 45% pyrolysis oil, 2. 35% carbon black, 3. 12 % steel, 4. 8% gas. oil report: gross calorific value 10500 kcal/ kg flash point 42 sulphur 1.17% density 0.92 viscosity 36.06 the perfect solution (pyrolysis process): pyrolysis is the decomposition of organic compounds under oxygen free (anaerobic) atmosphere that produces gas, oil, carbon black and steel. Efficient industrial pyrolysis is a process to treat the rubber and industrial plastic wastage as well. as a result of pyrolysis of wastage tyres one obtains, ü fuel oil (45% to 50%) the main oil product produced by our recycling application is the fuel oil that is wide used for industrial and commercial purposes. The oil has 45% to 50% of the amount of recycled scrap tyres, which will be carried with licensed tanker trucks. ücarbon black (30% to 35%) carbon black is the main product recycled by pyrolysis technology. The amount of recycled carbon black is 30% to 35% of the total amount of scrap tyres recycled in the system. carbon black produced by pyrolysis process (cbp) is more economical compared to carbon black produced primarily from petroleum and is more price-efficient to be used as an ingredient in the industries listed; § electric cable junketing § conveyor band § carrier bands § black nylon bag, plastic pipes § rubber additive § automotive spare parts § black colorant in rubber materials § industrial rubber products üsteel wire (10% to 15%) tyres contain steel wires and the amount range of 10% to 15% of the total tyre wastage ügas (5% to 8%) non-condense able gases arise during the pyrolysis process. profit of plant 10 tons waste tire oil refining equipment processing costs and profit no. items: cost of per batch 1 10 tons of waste tires 8t×11=88000 2 0.4 tons of coal or wood 0.4t×5=2000 3 water and electricity 3000 4 workers+other 2000+2000=4000 5 total cost 97000 no. items: income 1 crude oil 8t×40%×37=118400 2 carbon black 8t×35%×4=11200 3 steel wire 8t×15%×15=18000 4 gross profit 147600 5 daily net profit 50600 6 monthly net profit 25×52600=1265000 7 yearly net profit 12×1265000=15180000

Waste Tyre Recycling Plant

3,500,000 Per Units

1 Units (MOQ)

Waste Tyre Recycling Plant

Get Price Quote

Tyre Pyrolysis Recycling Plant with its unique renewable technology has come up with a concept of setting new standard in renewable energy, that includes using of waste tyres as a raw material and producing green fuel oil, carbon black, steel and gas. With global warming and utilization of rubber, it has now become necessary to recycle the waste and convert it in fuel oil in such a way that it is environment friendly. This is a unique technology and can change energy market scenario in a big way.

Waste Tire Recycling Plant

Get Price Quote

waste tyre recycle plant

Get Price Quote

The main features include high level safety, environmental attributes at par with international standards, easy & affordable maintenance, higher efficiency and commercial viability. The Plant is auto-controlled with PLC Panel. Crumb Rubber Line includes a broad range of customized shredders and granulators, which have higher efficiency, toughness and consistency. Fornnax Crumb Rubber Line generates pure rubber crumb for playground surfaces & powdered rubber which is used to manufacture extruded rubber parts.

Tyre Recycling Plant

Get Price Quote

Divya international is a leading manufacturer of waste tyre recycling pyrolysis plant and spare parts in india. We have 2.5 years of technical and practical experience of running plants. We have implemented pyrolysis technologies in our plants that allow industrial customers to improve performance while lowering environmental impact.

Tyre Recycling Plant

Get Price Quote

THE PLANT IS TOTALLY MANUFACTURED. 100% WASTAGE TYRE RECYCLING IS ACHIEVED. 100% POLLUTION FREE. NO CHEMICAL INGREDIENTS USED DURING PROCESS. VISIT FOR MOTHER PLANT DEMOSTRATION AT OUR SITE.

Waste Tyre Recycling Plant

Get Price Quote

waste tyre recycle plant

350 Per Piece

waste tyre recycle plant

3,600,000 Per

Waste Tyre Recycling Plant

Get Price Quote

Waste Tyre Recycling Plant, Rubber Bale Cutter, reclaim rubber machinery

Waste Tyre Recycling Plant

Get Price Quote

Waste Tyre Recycling Plant, reclaim rubber machinery

Tyre Recycling Plant

Get Price Quote

Tyre Recycling Plant, cnc wood engraving machines, Rubber Recycling Machine

tyre recycling plants

Get Price Quote

tyre recycling plants, Recycling Plant, Industrial Oil

Tyre Recycling Plant

Get Price Quote

Tyre Recycling Plant, Cement Ball Mill, cement plants, Mini Cement Plant